How can you leverage the sterile properties of the Aseptic Bag-In-Box system to ensure that products maintain a long shelf life during long-distance transportation?

To take advantage of the sterile properties of the Aseptic Bag-In-Box (BIB) system to ensure that products can maintain a long shelf life during long-distance transportation, several key measures can be taken:

Strict production environment control: During the filling and packaging process, ensure that the production environment meets sterile standards. This includes the use of high-efficiency filtration systems, ultraviolet disinfection and other necessary cleaning and disinfection measures to reduce the risk of microbial contamination.

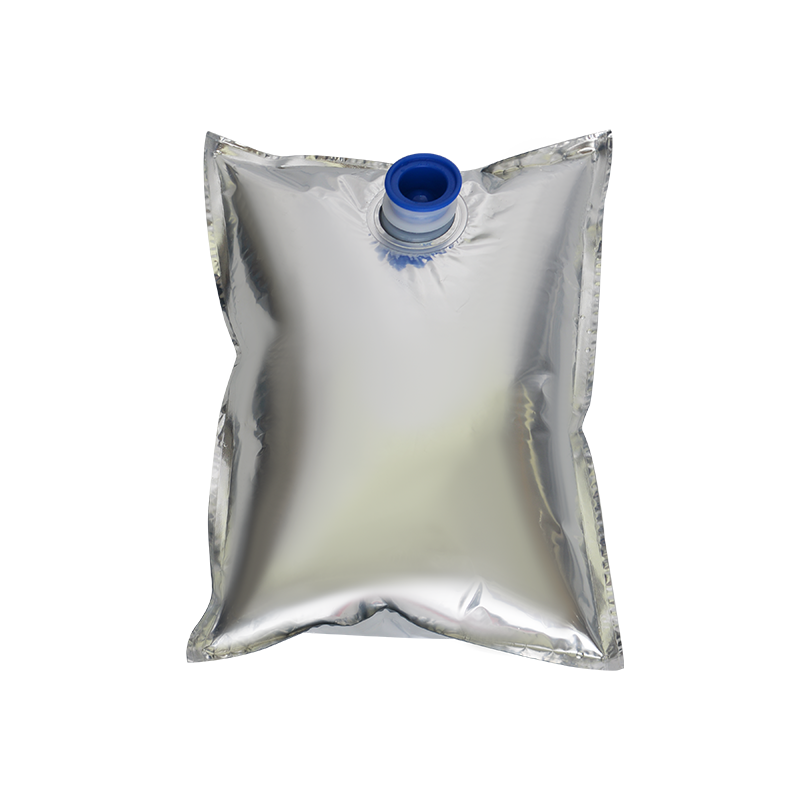

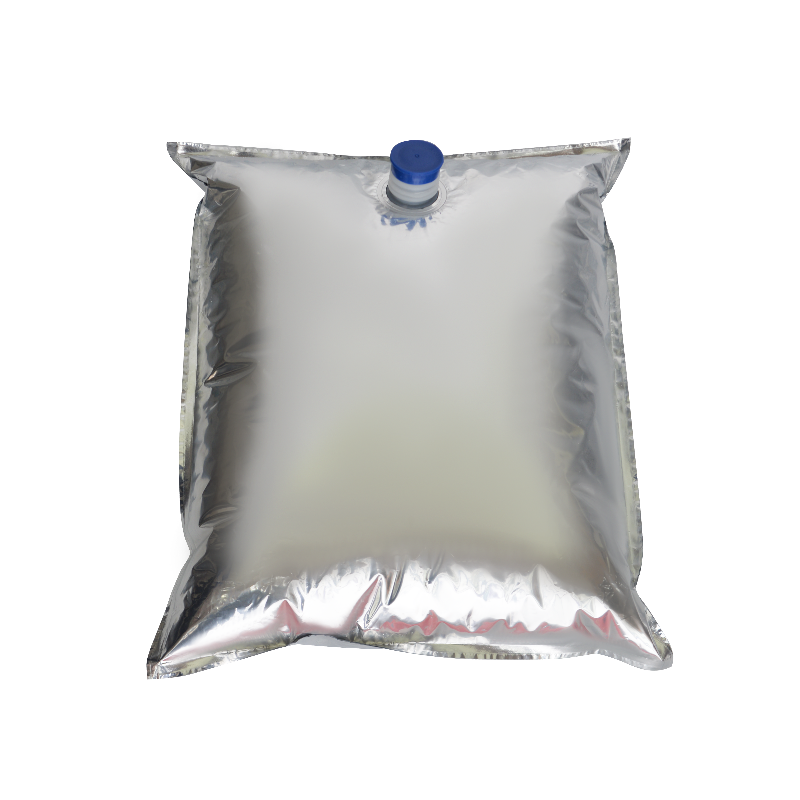

Aseptic filling technology: Using strictly sterilized and cleaned filling equipment, products are filled in a sterile environment. This ensures that products are not contaminated before entering BIB packaging.

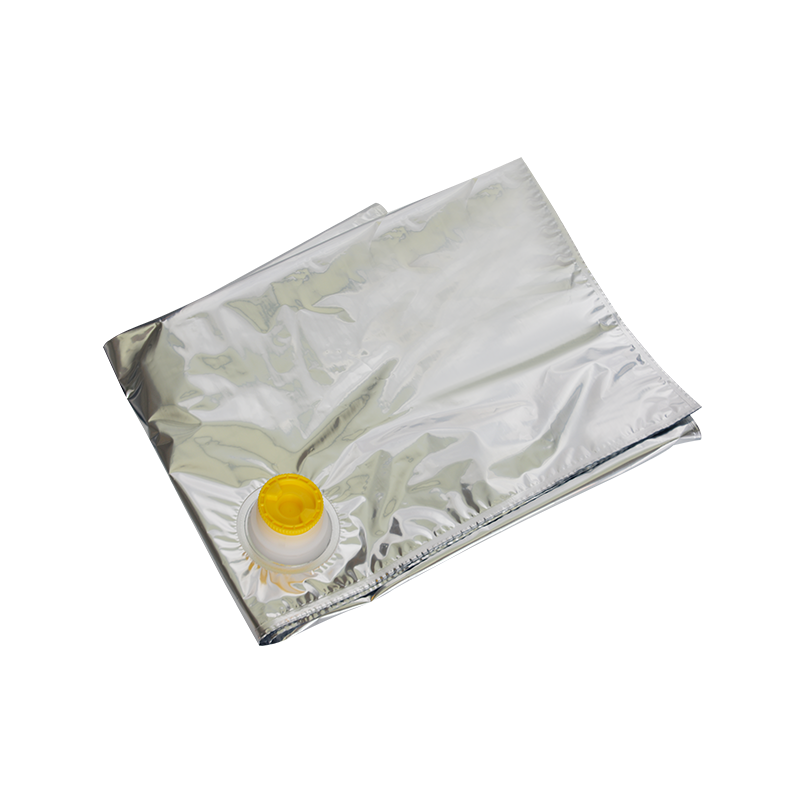

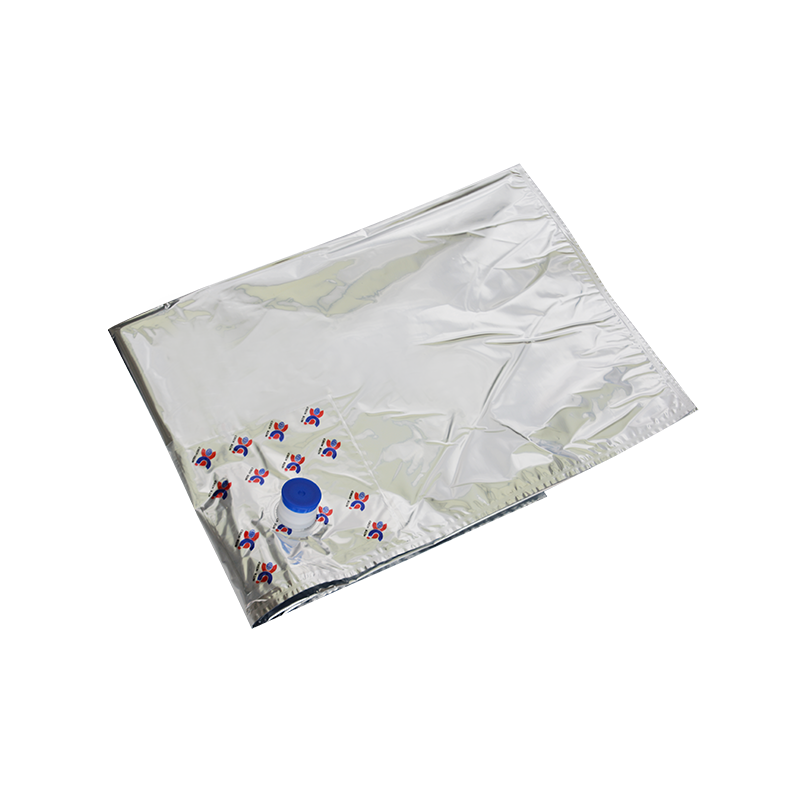

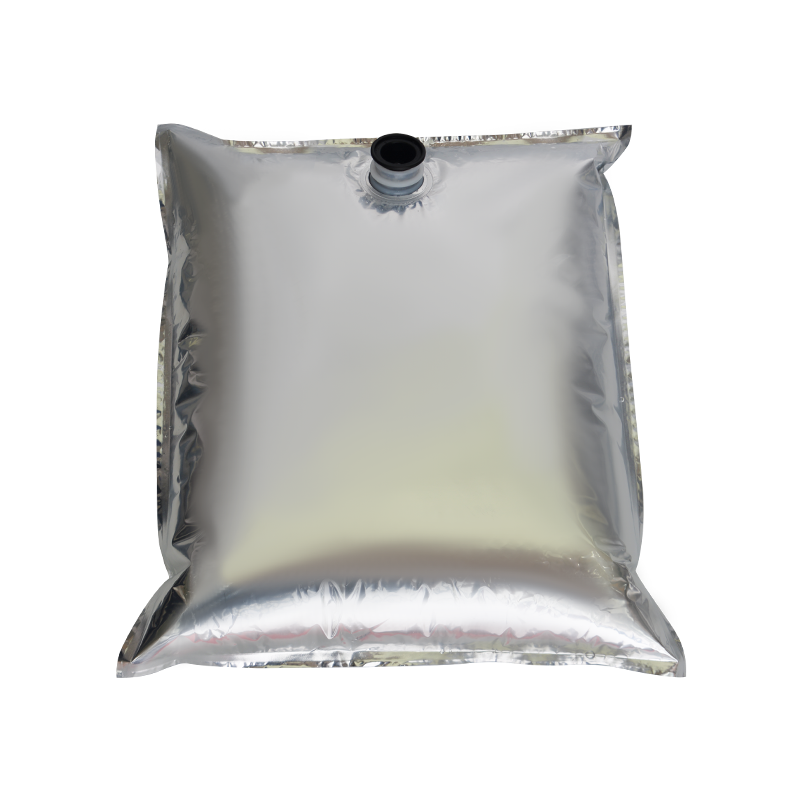

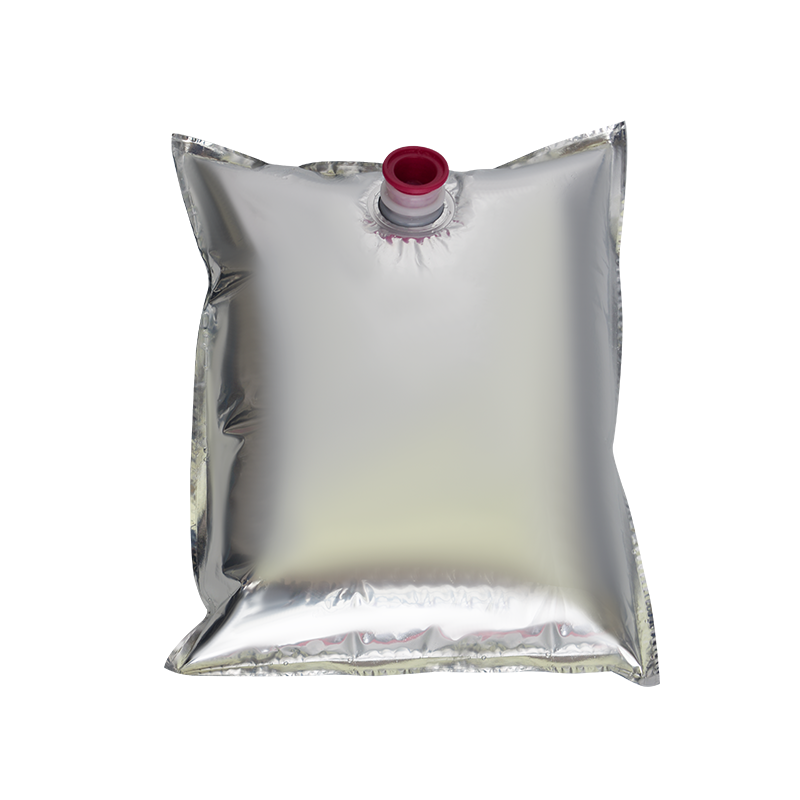

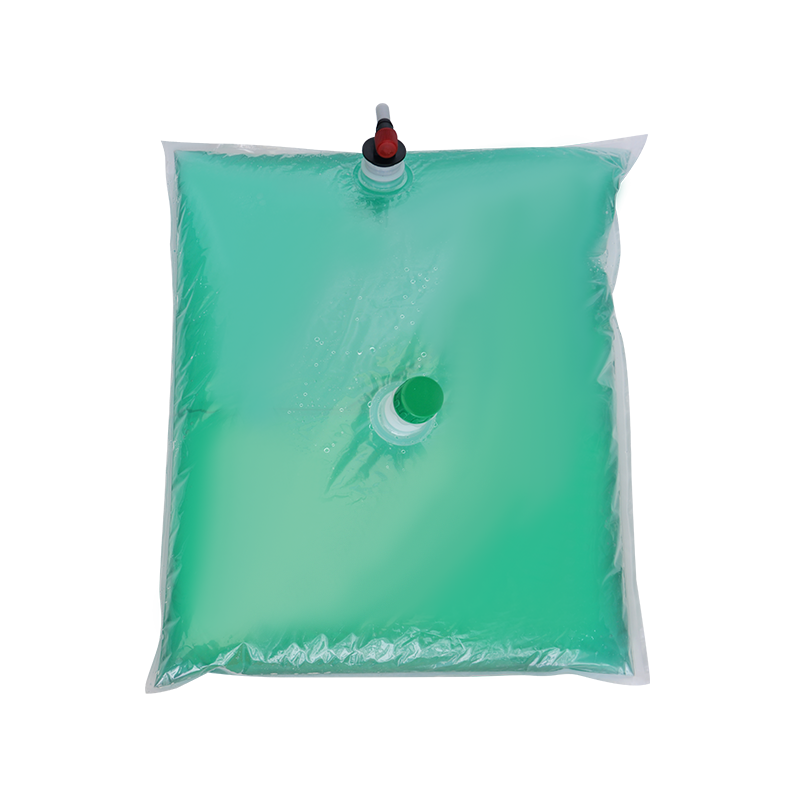

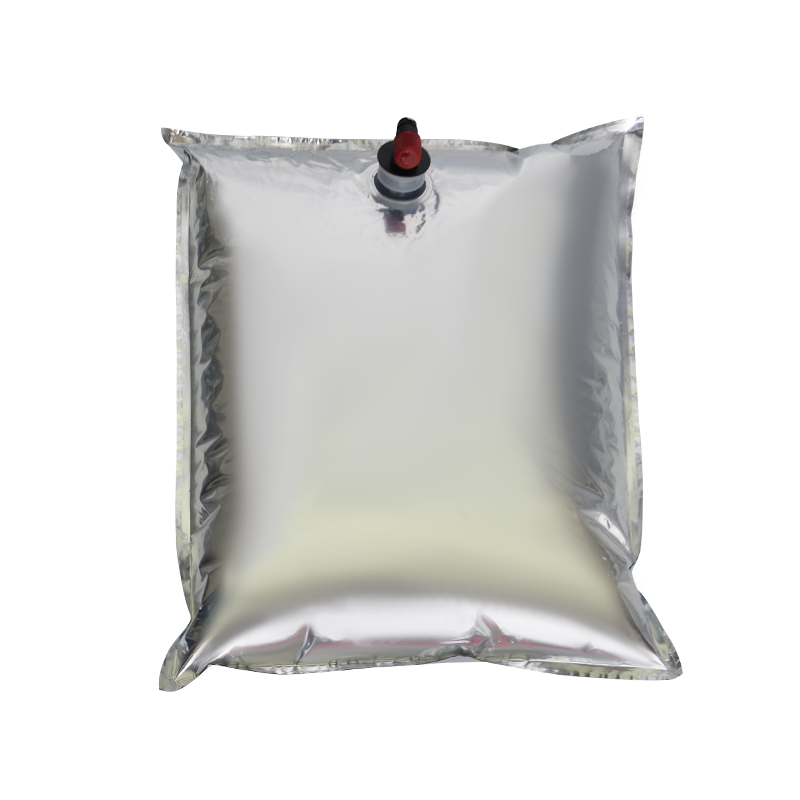

High-quality packaging materials: Choose high-quality BIB packaging materials with excellent barrier properties. These materials can effectively prevent external microorganisms, oxygen and moisture from entering the interior of the packaging, thereby maintaining the sterility of the product.

Proper package design and sealing: Ensure BIB packaging is properly designed, easy to open and close, and effectively maintains sterility when sealed. Use reliable sealing technology and materials to ensure that the packaging will not break or leak during long-distance transportation.

Temperature control during transportation: During long-distance transportation, ensure that products are within the appropriate temperature range. This can be accomplished through the use of refrigerated trucks, insulated boxes, or other temperature-controlled equipment. Proper temperature control can slow down the growth of microorganisms, thereby extending the shelf life of products.

Strict inspection and quality control: Strict inspection and quality control are carried out during production and transportation. This includes sampling and testing of raw materials, semi-finished products and finished products to ensure they meet sterility and quality requirements. At the same time, the packaging and transportation processes are monitored and recorded so that if problems arise, they can be quickly traced and resolved.

Proper Storage and Handling: After receiving the product, the consumer or retailer needs to store and handle the product correctly according to the instructions. This includes storing products at appropriate temperatures, avoiding direct sunlight and moisture. Proper storage and handling ensures that the product maintains a long shelf life.

By taking the above measures, the sterile properties of the Aseptic Bag-In-Box system can be fully utilized to ensure that products can maintain a long shelf life during long-distance transportation.

English

English русский

русский