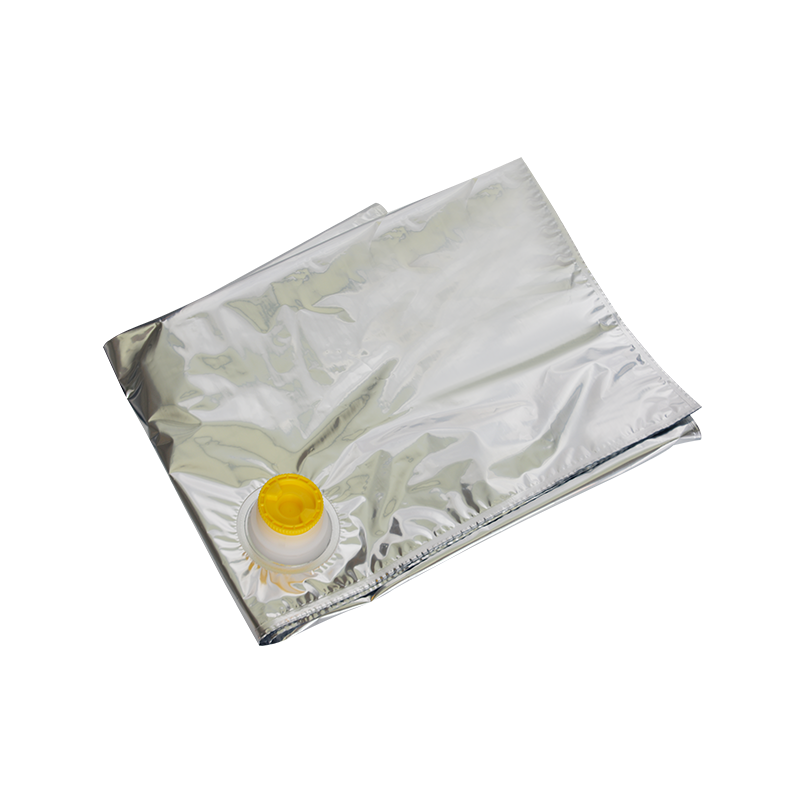

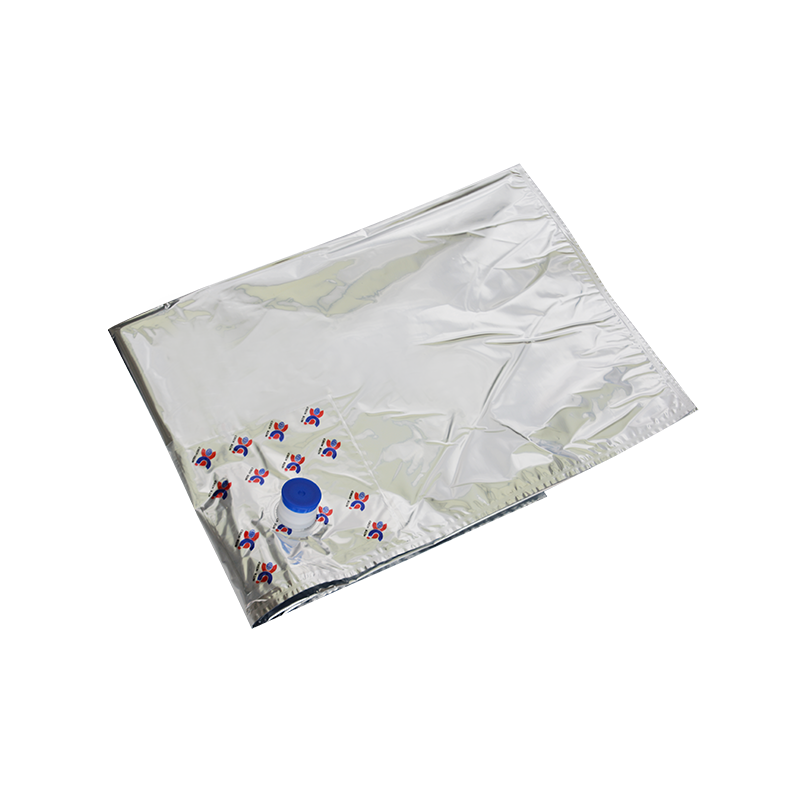

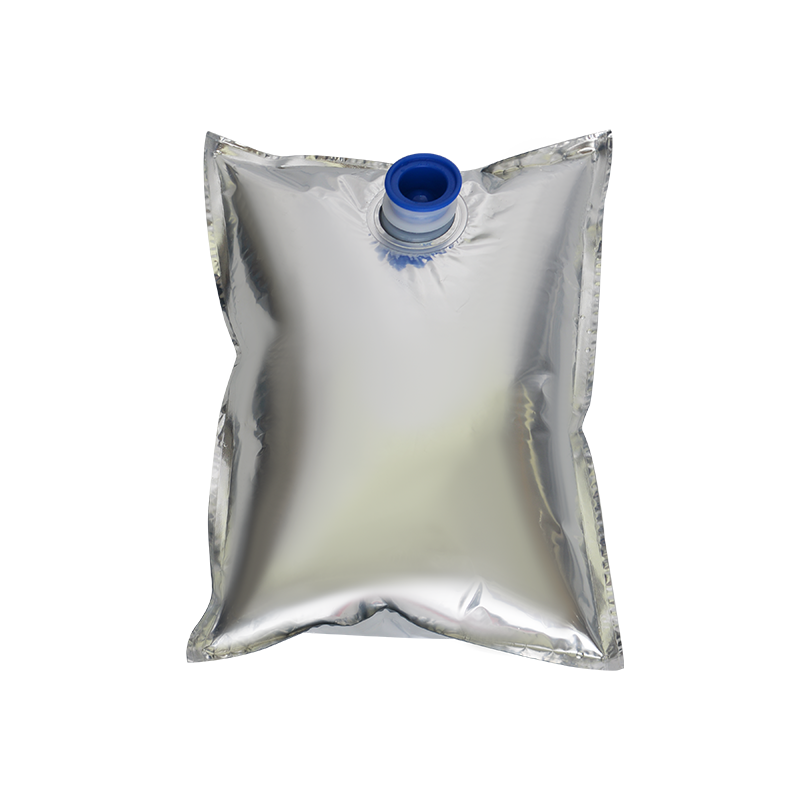

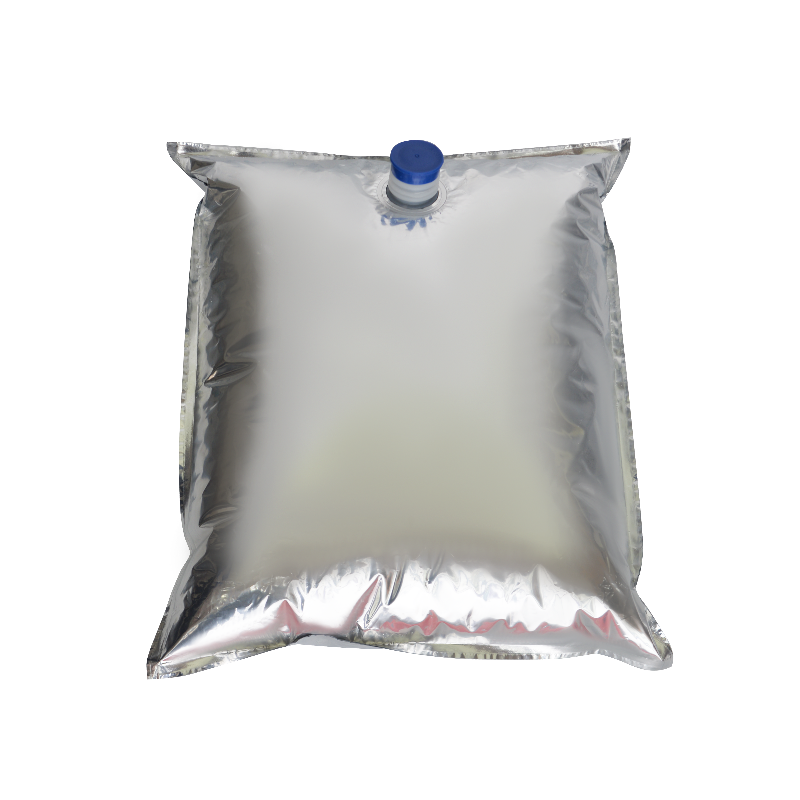

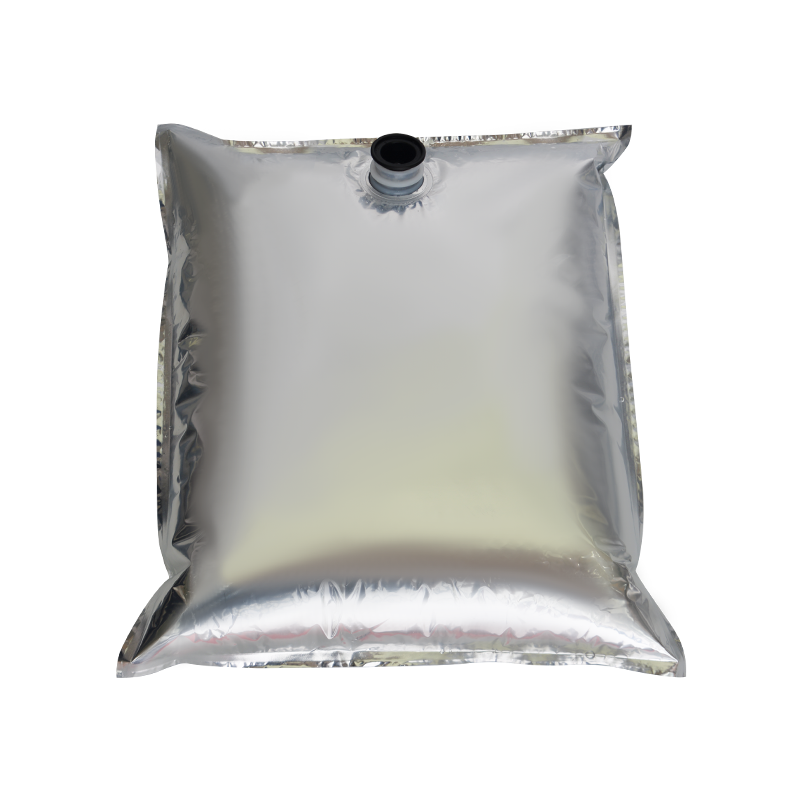

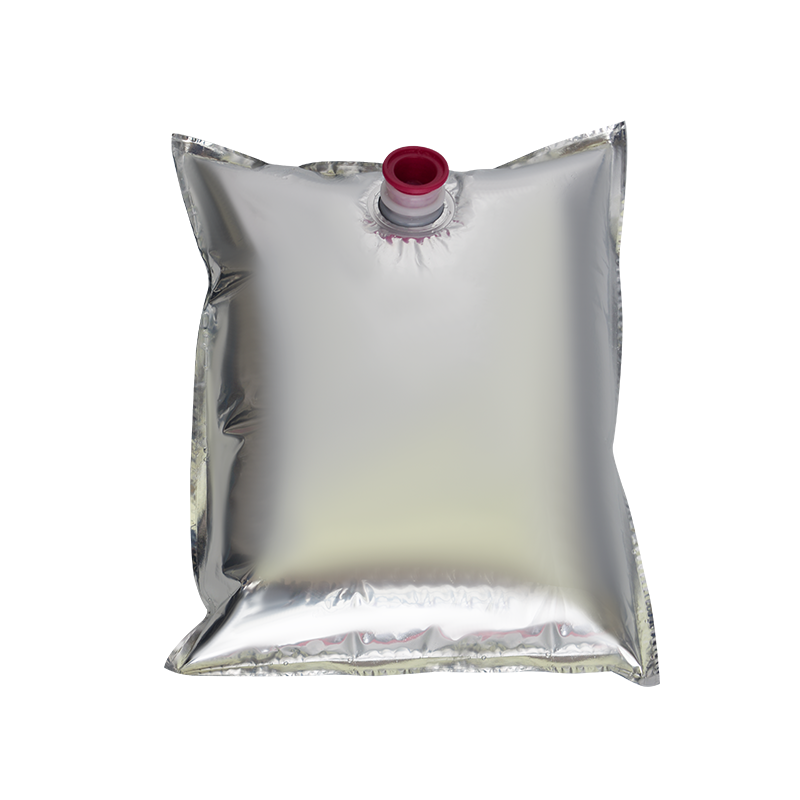

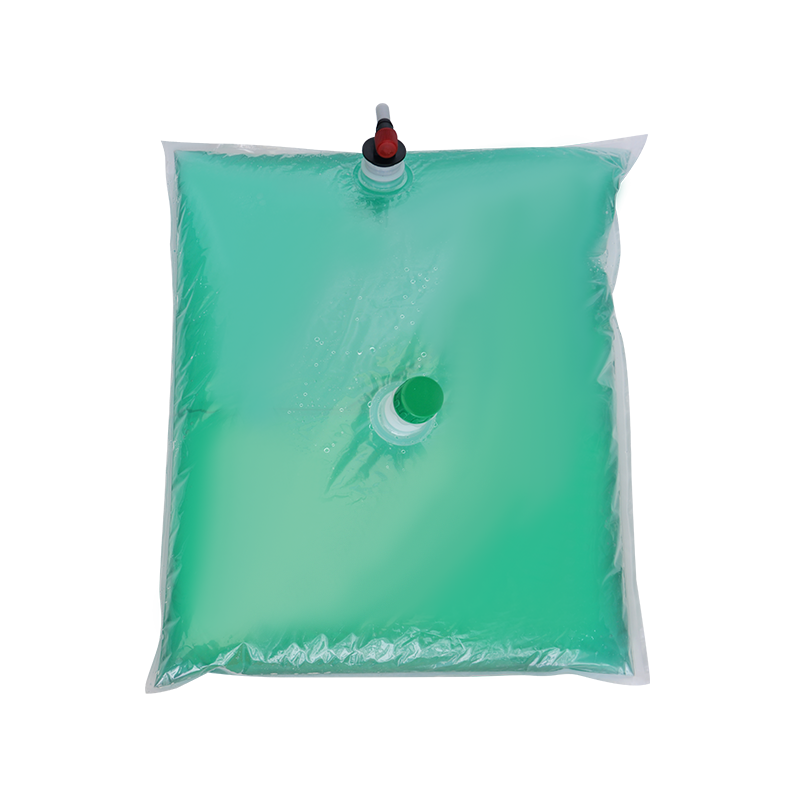

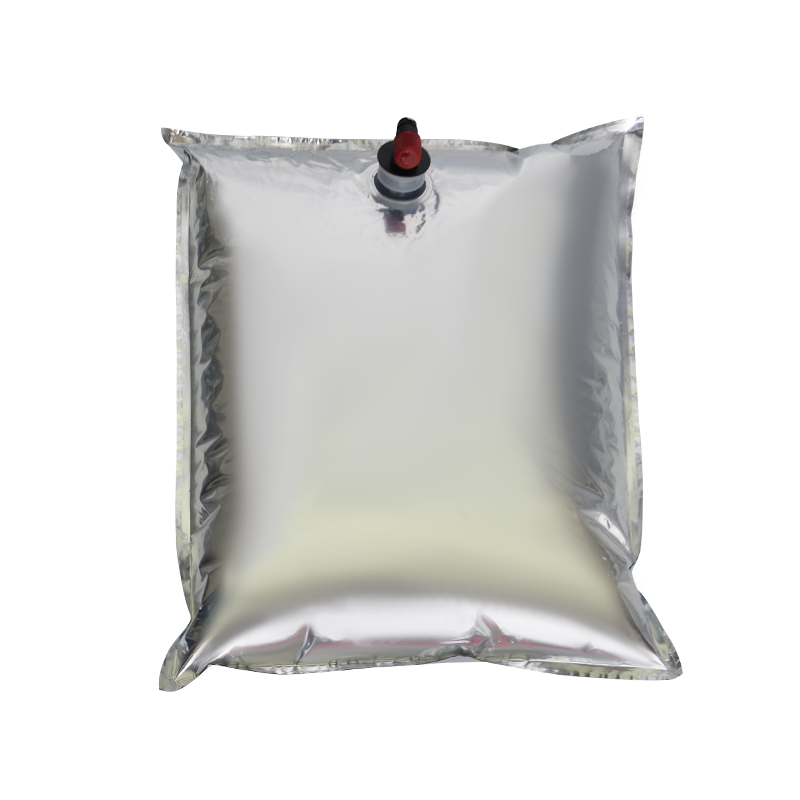

Aseptic bags, as a special packaging material, are widely used in medicine, food, biotechnology and other fields. Their unique sterile characteristics are crucial to ensuring the quality and safety of products. And all of this is inseparable from the clean environment control during its manufacturing process.

The creation of a clean environment is the basis for ensuring the sterility of Aseptic bags. The manufacturing workshop of Aseptic bags needs to reach a cleanliness level of C or above, which means that the number of dust particles and sedimentation bacteria in the workshop is strictly controlled at an extremely low level. In order to meet such standards, the workshop will use an advanced air purification system to continuously circulate and filter the air in the workshop to remove dust and microorganisms. At the same time, the doors, windows, floors, walls, etc. of the workshop will be made of materials that are easy to clean and disinfect to ensure the cleanliness of the entire workshop environment.

In such a clean environment, the manufacturing process of sterile bags can proceed smoothly. But it is not enough to rely solely on the cleanliness of the environment. The workshop and operators also need to carry out strict disinfection and sterilization. Before each production, the workshop will be thoroughly cleaned and disinfected to ensure that no microorganisms remain. Operators need to wear special clean clothes and undergo strict hand washing and disinfection procedures before entering the workshop for operation. Such measures further reduce the risk of microbial contamination and ensure the sterility of the sterile bag manufacturing process.

The creation of a clean environment and strict disinfection and sterilization measures together constitute an important guarantee in the sterile bag manufacturing process. In such an environment, the manufacturing process of sterile bags can proceed smoothly, ensuring the sterility inside them. This sterile state is crucial to ensuring product quality and safety.

In addition to the cleanliness of the manufacturing environment, the manufacturing process of sterile bags also requires strict control of other factors, such as material selection, precise control of the manufacturing process, etc. Only by strictly controlling these aspects can the sterility and reliability of the final product be ensured.

The manufacturing process of sterile bags needs to be carried out in a clean environment, which is the basis for ensuring sterility. Through strict disinfection and sterilization measures and the creation of a clean environment, we can ensure the sterility of the sterile bag manufacturing process, thus ensuring the quality and safety of the product.

English

English русский

русский