In the rapidly developing modern logistics system, efficient and safe storage and transportation are the key to ensure the maximization of product value and market response speed. Especially in the circulation of liquid products, traditional packaging methods often face challenges such as low space utilization, high transportation costs, and poor environmental adaptability. The emergence of the bag-in-box liquid valve system provides a revolutionary solution to these problems. With its unique design concept and excellent performance, it has become a new favorite in the field of liquid product storage and transportation.

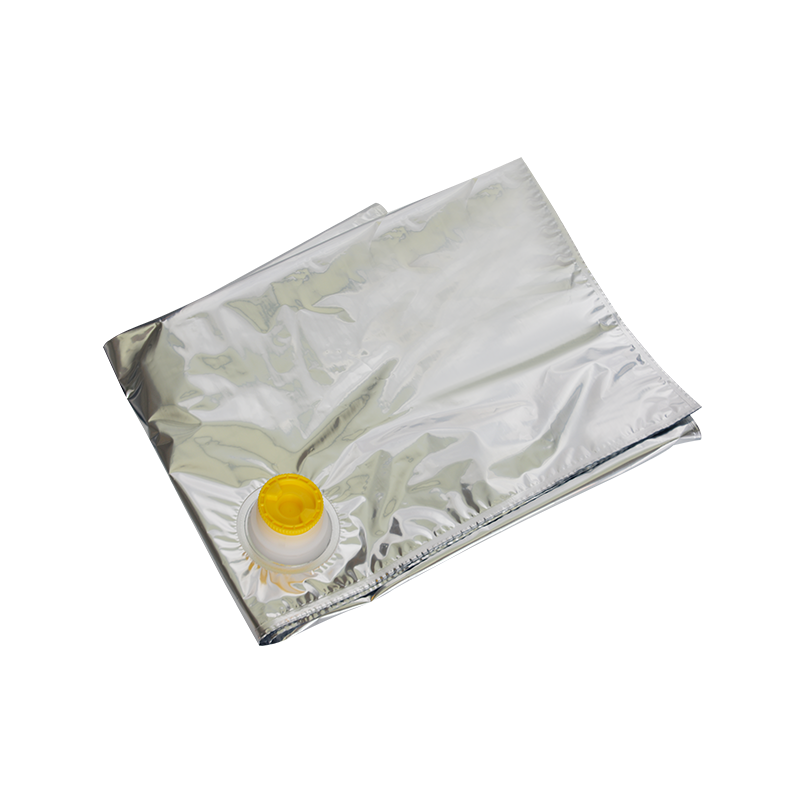

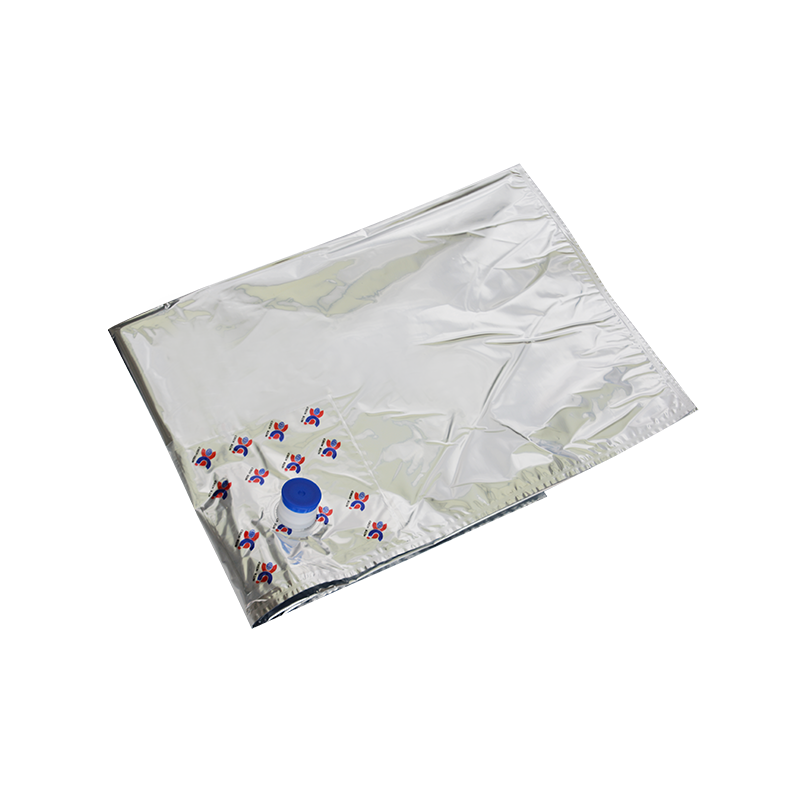

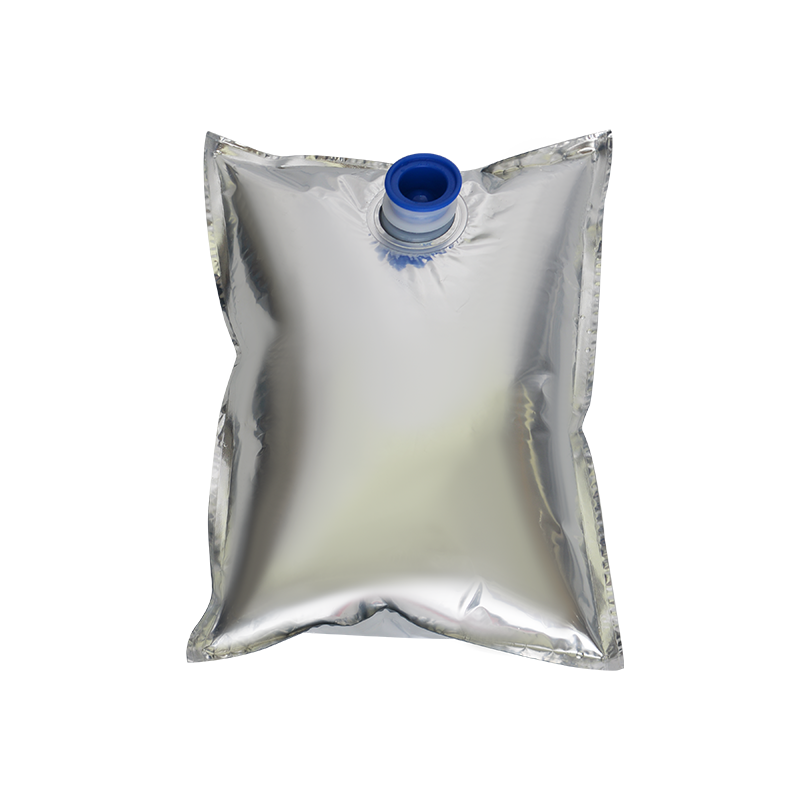

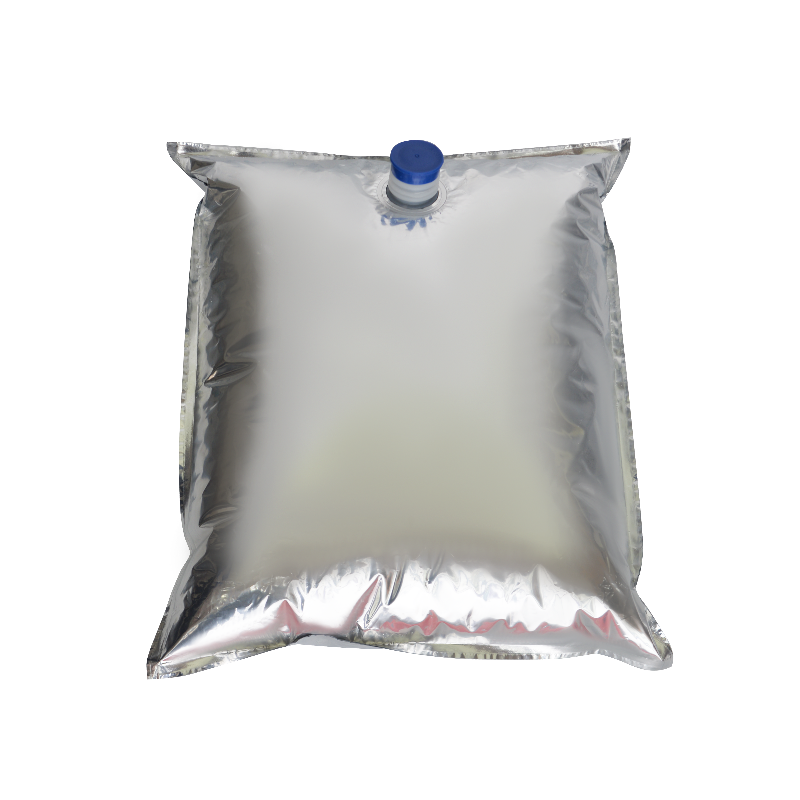

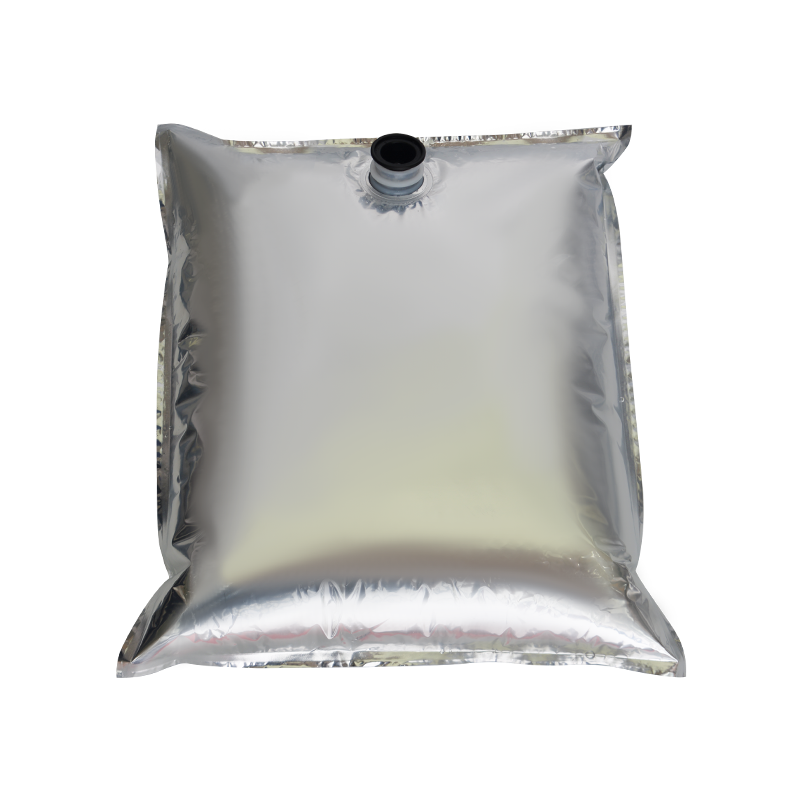

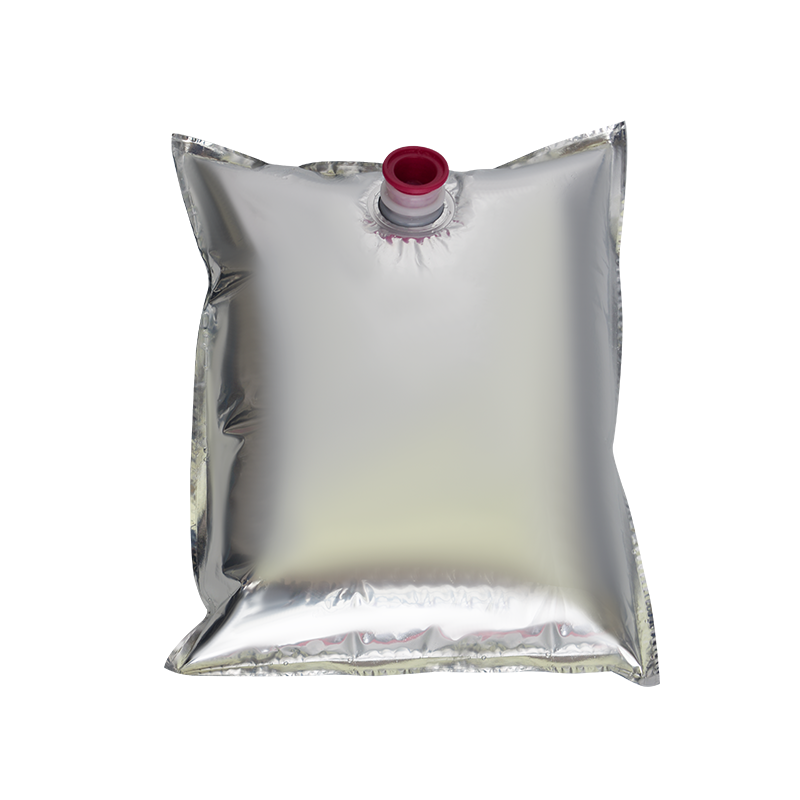

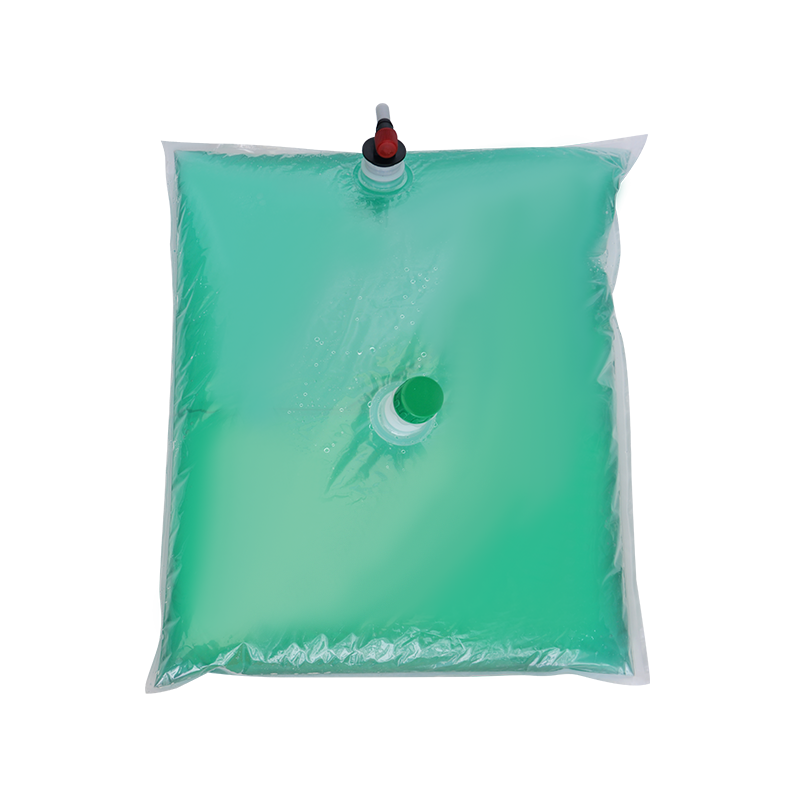

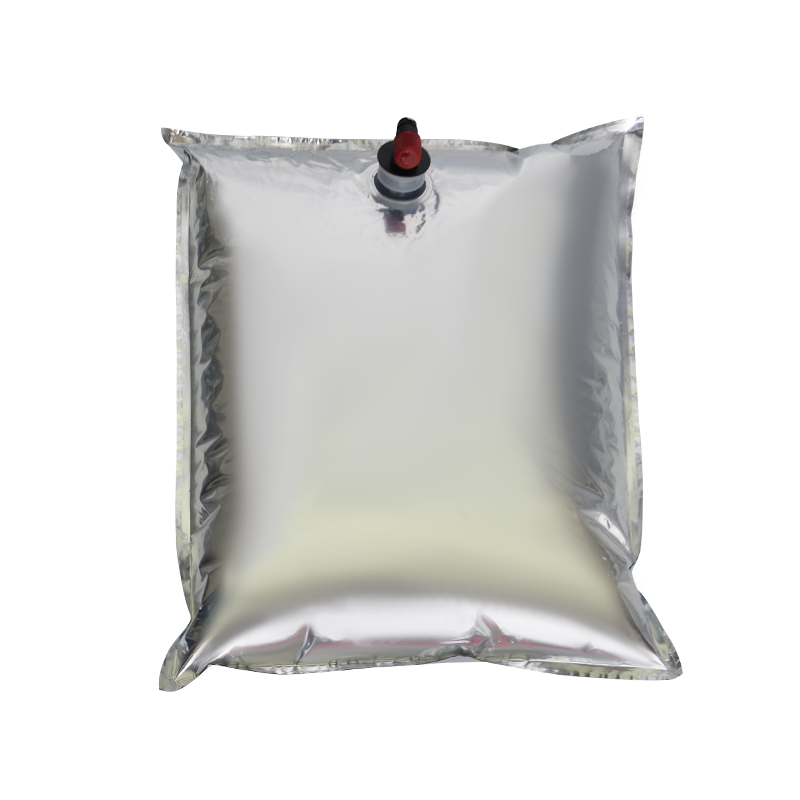

The core of the bag-in-box liquid valve system lies in its internal flexible bag structure. This bag is made of multi-layer composite materials. It not only has excellent corrosion resistance, barrier and puncture resistance, but also can be freely deformed according to the actual capacity of the internal liquid, thereby maximizing the use of space.

Compared with traditional rigid packaging, such as iron barrels and plastic barrels, bags in boxes can reduce the amount of packaging materials by up to 30% to 50%, while significantly increasing the liquid loading per unit volume without sacrificing protection performance. This efficient storage method not only reduces packaging costs, but also reduces space occupation during warehousing and transportation, and improves overall operational efficiency.

In the transportation link, the bag-in-box liquid valve system also performs well. Its external rigid packaging box provides solid support and protection for the internal flexible bag, effectively resisting vibration, impact and extrusion during transportation, ensuring the integrity and safety of the product.

The precise design of the valve system is also an important part of ensuring safe transportation. By adopting high-quality sealing materials and advanced manufacturing processes, the valve can maintain stable sealing performance in harsh transportation environments, prevent liquid leakage, and reduce transportation risks.

Another significant advantage of the bag-in-box liquid valve system is its high flexibility and customizability. Whether it is a small batch, multi-variety liquid product or a large batch, single variety of liquid raw materials, the size, material and valve configuration of the flexible bag can be adjusted to meet different storage and transportation needs. This flexibility enables the bag-in-box liquid valve system to be widely used in multiple industries such as food, beverage, medicine, and chemical industry, becoming an ideal choice for the storage and transportation of cross-industry liquid products.

Today, environmental protection and sustainable development have become an irreversible trend worldwide. The bag-in-box liquid valve system is particularly dazzling in this context with its environmentally friendly characteristics. Its internal flexible bags are mostly made of recyclable or degradable materials, reducing the consumption of natural resources and environmental pollution.

The bag-in-box liquid valve system is gradually changing the traditional pattern of liquid product storage and transportation with its advantages of high efficiency, safety, flexibility and environmental protection. In the future, the bag-in-box liquid valve system is expected to become a shining pearl in the field of liquid product packaging, leading the industry to a more green, intelligent and efficient direction.

English

English русский

русский