In the pharmaceutical field, the safety and stability of drugs are crucial. As the "protective shell" of drugs, the choice of packaging materials cannot be sloppy. In recent years, aluminum foil composite aseptic bags have gradually emerged in the pharmaceutical industry with their excellent performance and have become the trusted choice of many pharmaceutical companies and medical institutions.

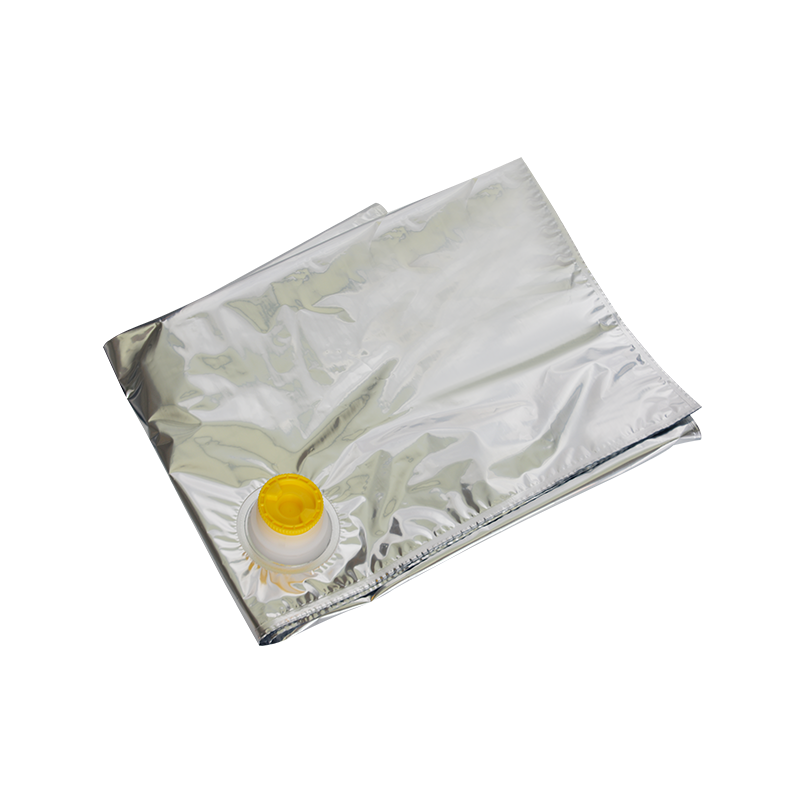

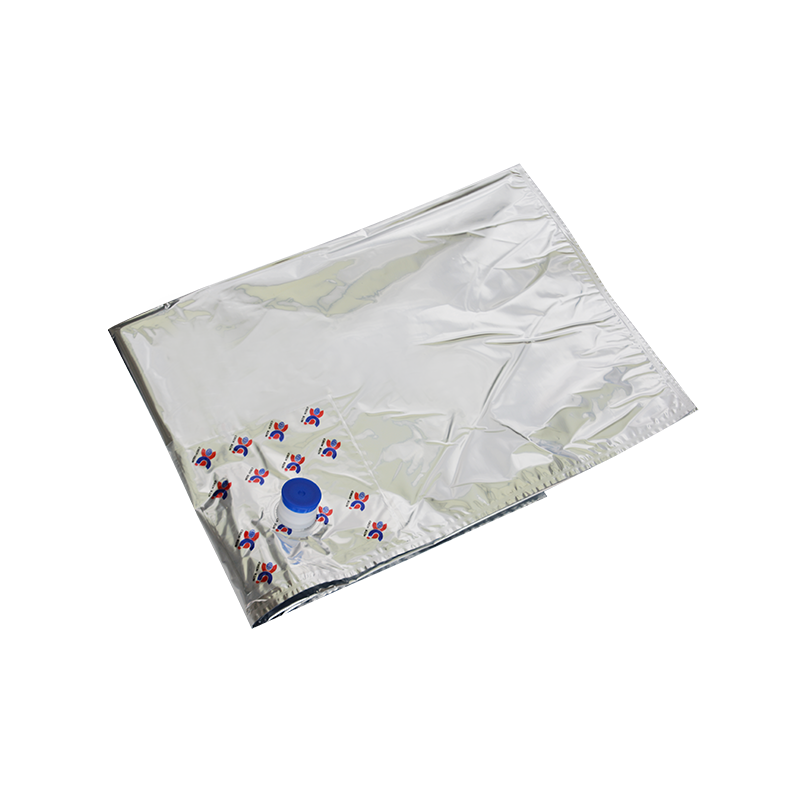

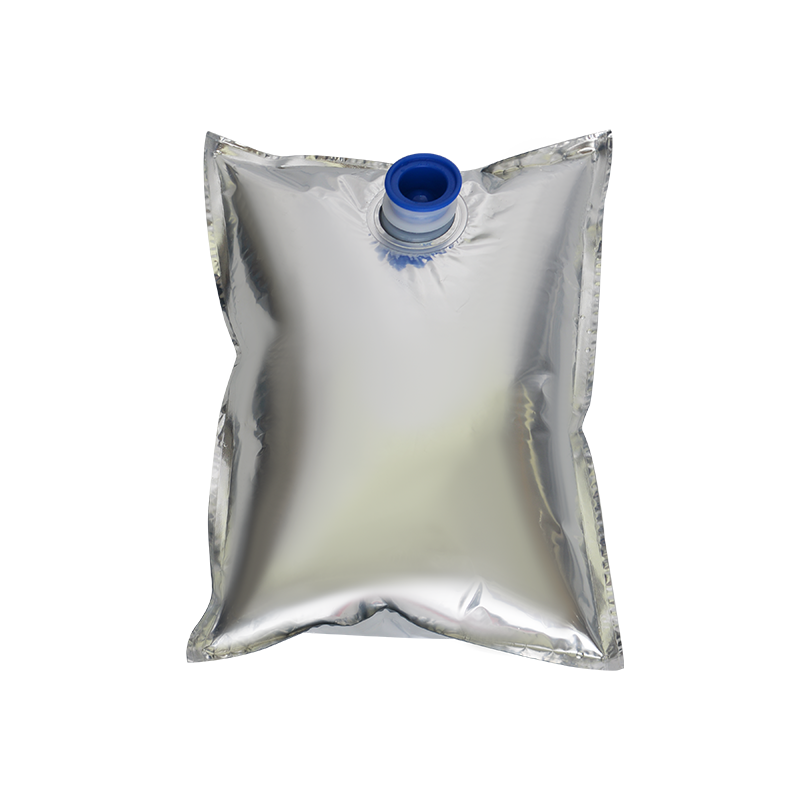

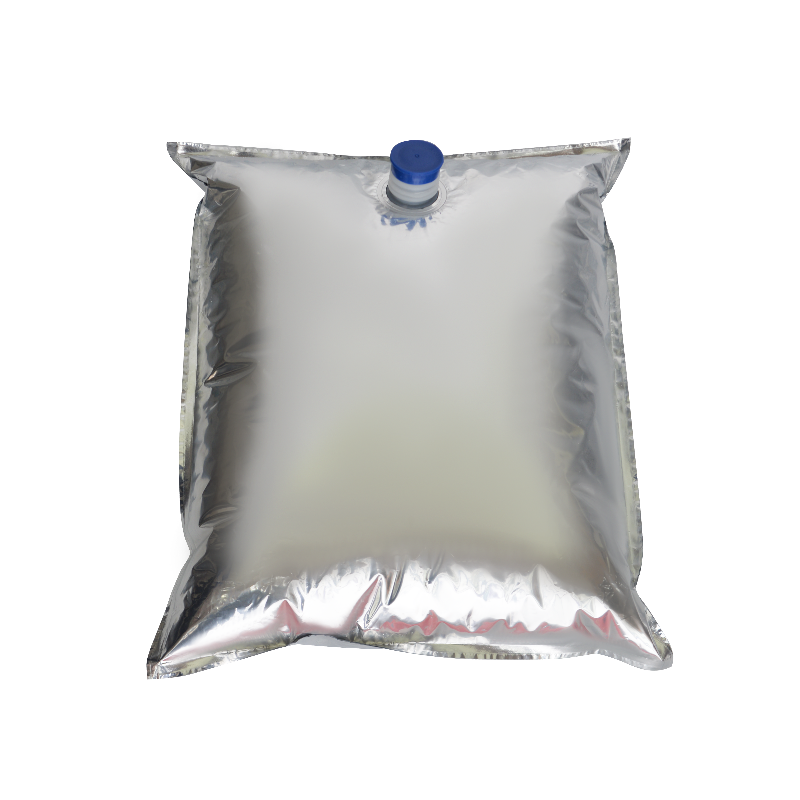

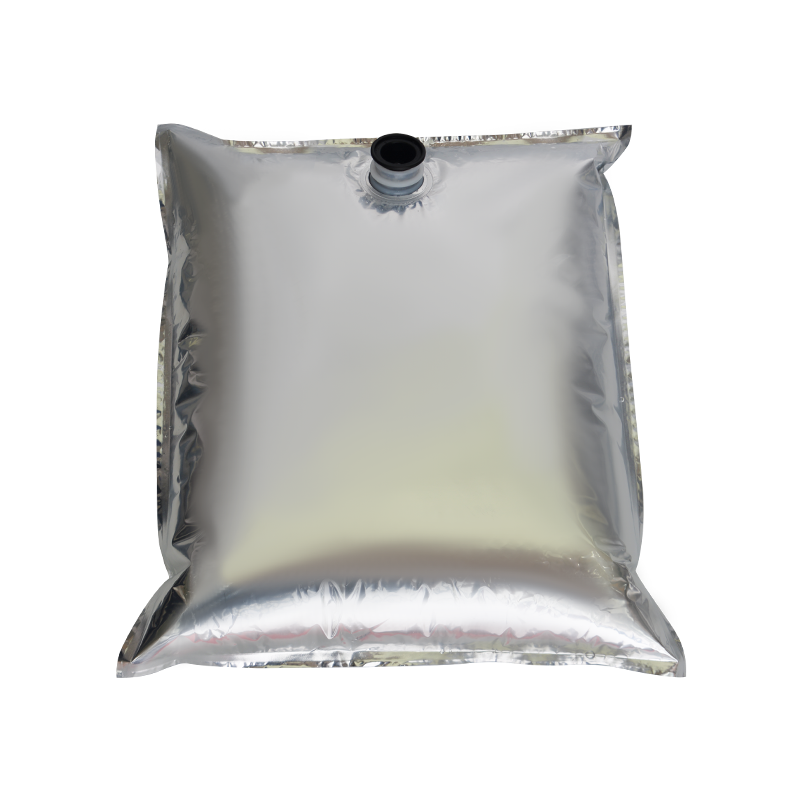

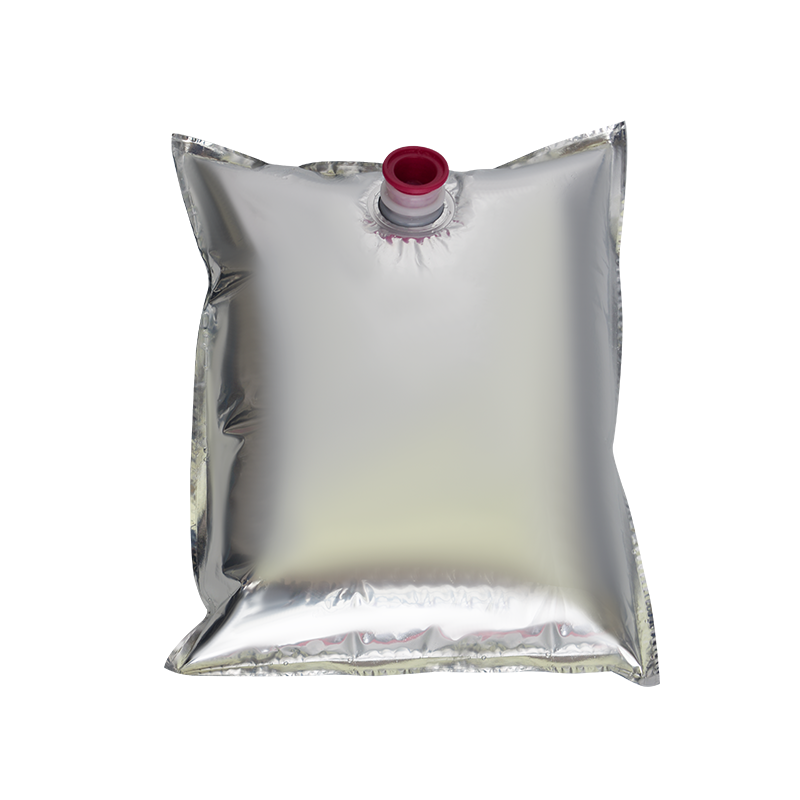

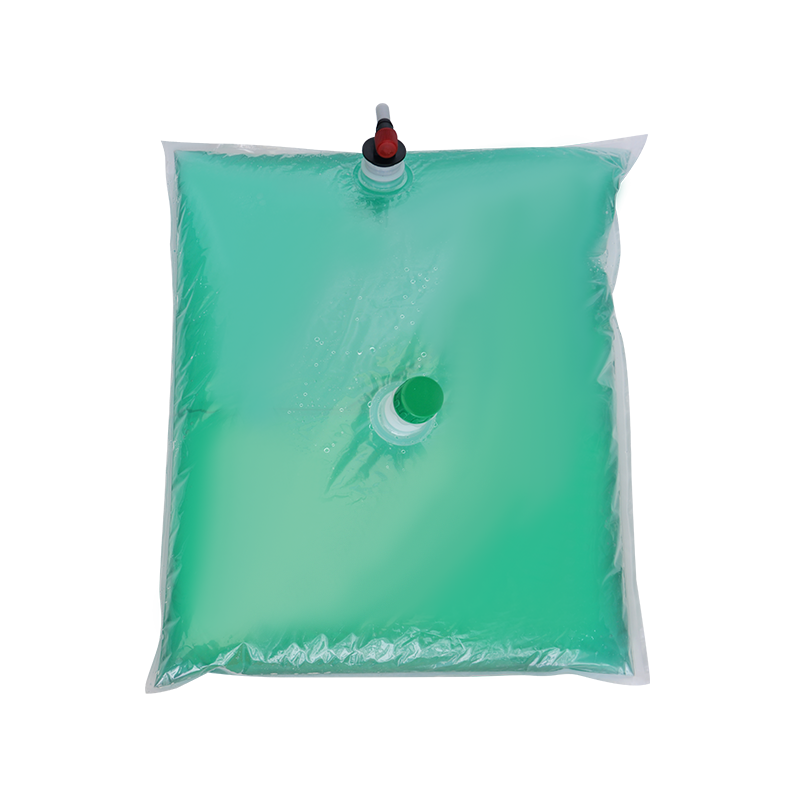

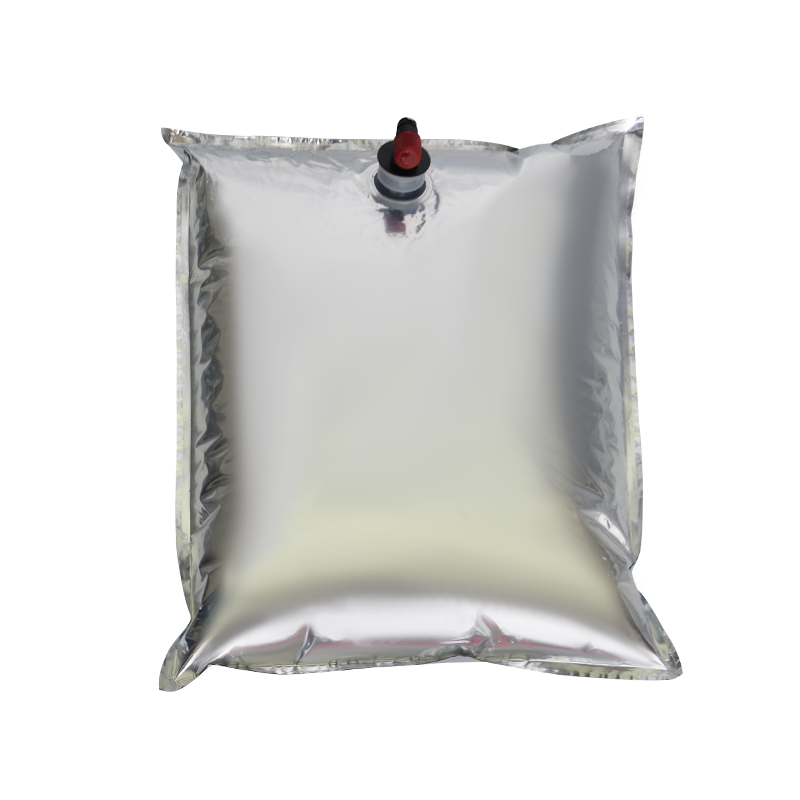

The reason why aluminum foil composite aseptic bags are favored in the pharmaceutical industry is first due to their excellent performance advantages. The outer layer is made of high-purity aluminum foil, which has excellent barrier properties and can effectively prevent the invasion of light, oxygen and microorganisms, ensuring that the drugs will not be contaminated by the outside world during storage and transportation. The inner layer is made of food-grade plastic film, which not only has good sealing and moisture resistance, but also effectively prevents drugs from getting damp, oxidized and deteriorating. Aluminum foil composite aseptic bags also have excellent high and low temperature resistance, which can adapt to the storage needs of drugs under various environmental conditions.

In the pharmaceutical industry, aluminum foil composite aseptic bags are widely used. In the packaging of solid drugs, whether it is tablets, capsules or granules, aluminum foil composite aseptic bags can provide reliable moisture, oxidation and pollution protection. Its unique sealing performance ensures that the medicine remains dry and pure before opening, thereby extending the shelf life of the medicine. Aluminum foil composite aseptic bags also perform well in the packaging of liquid medicines. Its soft inner layer material can fit the shape of the medicine closely, reduce the air contact area, and reduce the risk of medicine oxidation and deterioration. Aluminum foil composite aseptic bags are also widely used in the packaging of medical devices. Medical devices need to remain sterile during storage and transportation, and aluminum foil composite aseptic bags can provide a safe and sterile packaging environment to ensure the cleanliness and safety of medical devices.

With the advancement of science and technology and the development of the pharmaceutical industry, aluminum foil composite aseptic bags will show a broader application prospect in the future. Intelligent packaging will become an important development trend in the pharmaceutical industry. By integrating advanced technologies such as sensors and RFID into aluminum foil composite aseptic bags, we can achieve real-time tracking and monitoring of drug information. This not only helps to improve the safety and traceability of drugs, but also provides strong support for the supply chain management of drugs. The application of environmentally friendly materials will gradually become mainstream. With the improvement of global environmental awareness, the pharmaceutical industry will also pay more attention to the environmental performance of packaging materials. In the future, aluminum foil composite aseptic bags will actively explore the application of environmentally friendly materials such as degradable materials and bio-based materials to reduce the impact of products on the environment.

The demand for personalized customization will also become an important trend in the pharmaceutical industry. Different pharmaceutical companies and medical institutions have different needs for packaging materials, and the customized services of aluminum foil composite aseptic bags will be increasingly valued. By providing a variety of colors, patterns and size options, we can meet the personalized needs of different customers and enhance the market competitiveness of products.

Aluminum foil composite aseptic bags play an important role in the pharmaceutical industry with their excellent performance and wide range of applications. In the future, with the continuous advancement of technology and the diversification of consumer demand, aluminum foil composite aseptic bags will continue to play an important role in the pharmaceutical industry, providing more reliable guarantees for the safety and stability of drugs. We also look forward to the continuous innovation and development of this packaging material in the future, and make greater contributions to the prosperity of the pharmaceutical industry.

English

English русский

русский