In today's era of pursuing high efficiency, environmental protection and sustainable development, the bag-in-box liquid valve technology is gradually becoming an indispensable force in the field of liquid product packaging with its unique technological innovation and significant advantages. This technology not only integrates the essence of traditional packaging, but also achieves breakthroughs in multiple dimensions, bringing changes to the industry.

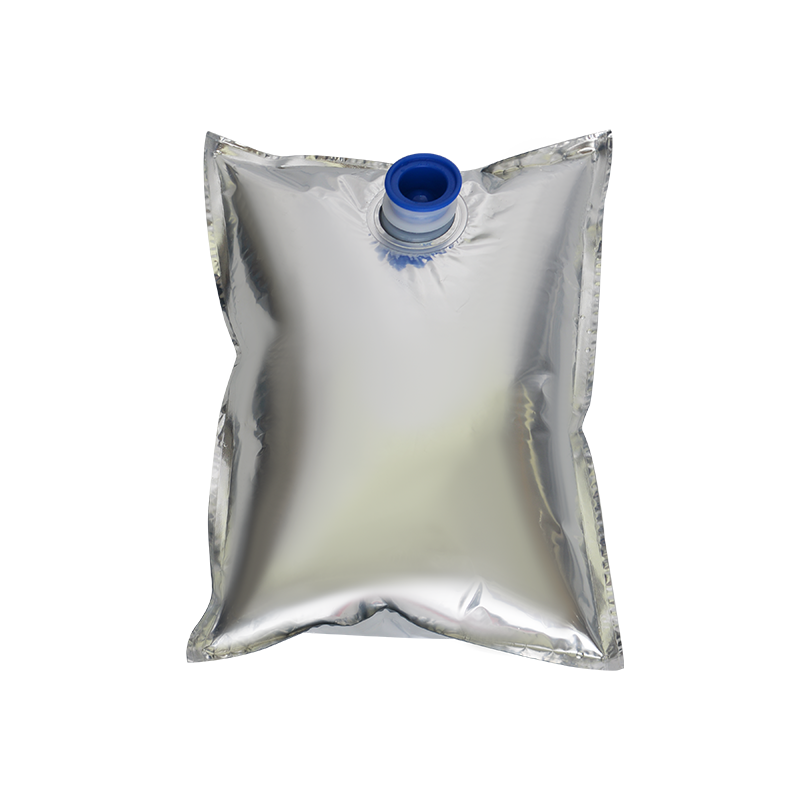

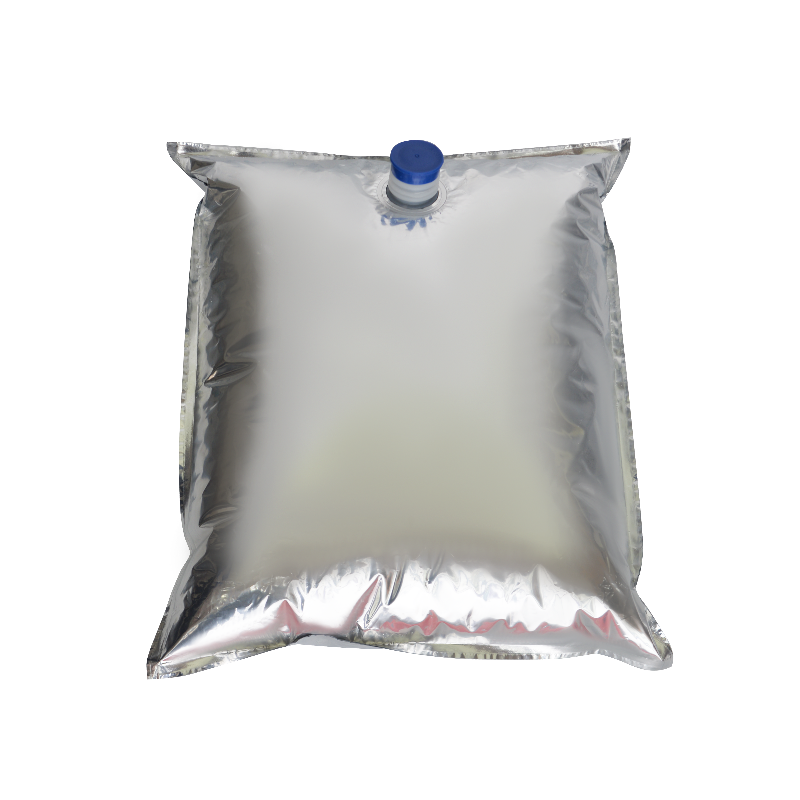

The core of the bag-in-box liquid valve lies in its built-in precision valve system. These valves are carefully designed to accurately control the outflow speed, flow rate and direction of the liquid. By adopting advanced sealing technology and materials, the valves not only ensure sealing, but also have good durability and corrosion resistance, ensuring stable performance during long-term use. In addition, some high-end valves also integrate anti-backflow mechanisms to effectively prevent external contaminants from entering the packaging, ensuring the purity and safety of liquid products.

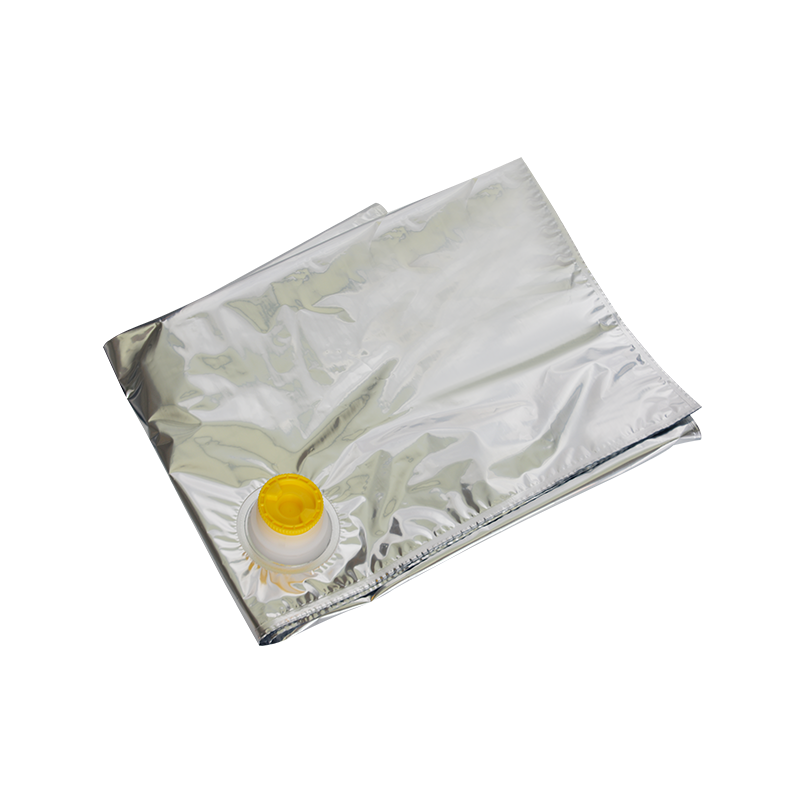

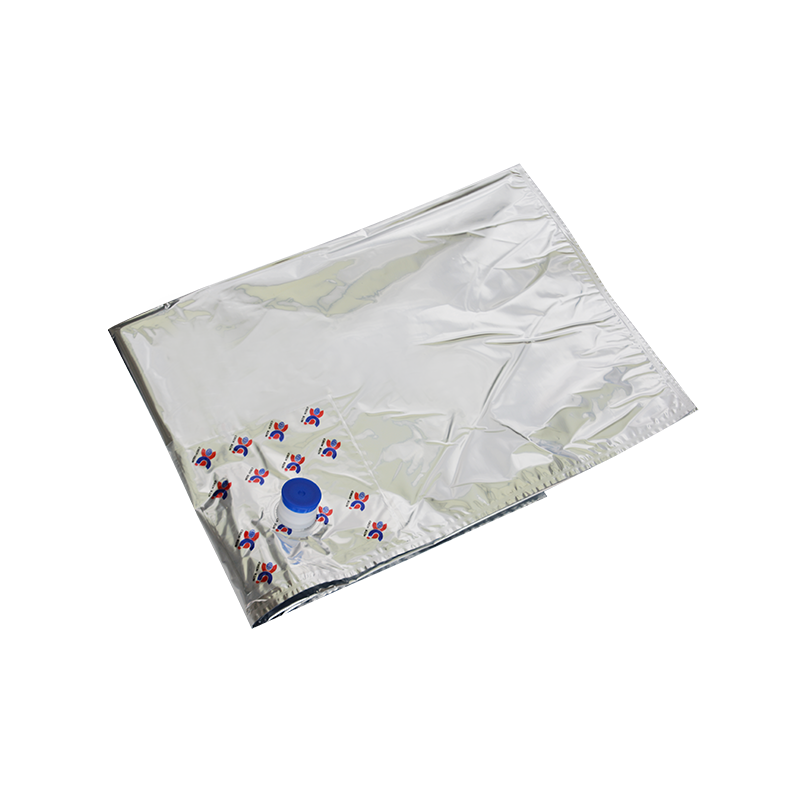

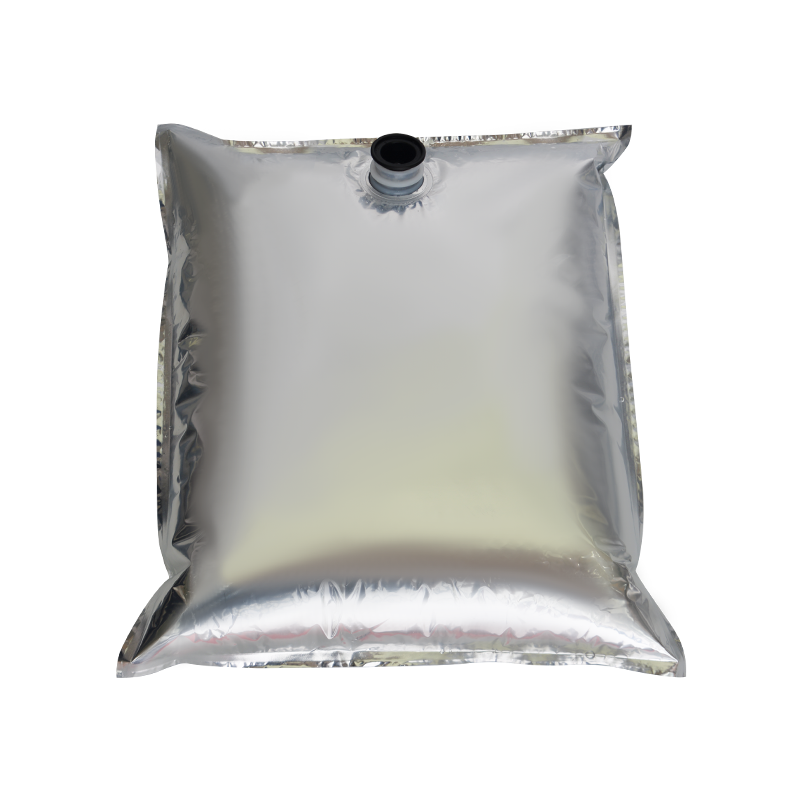

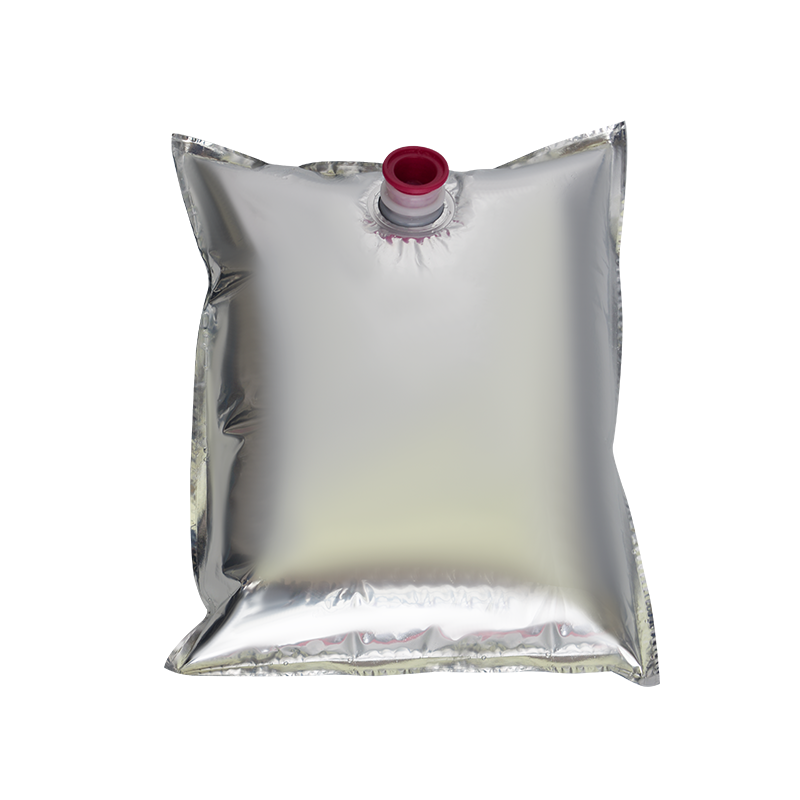

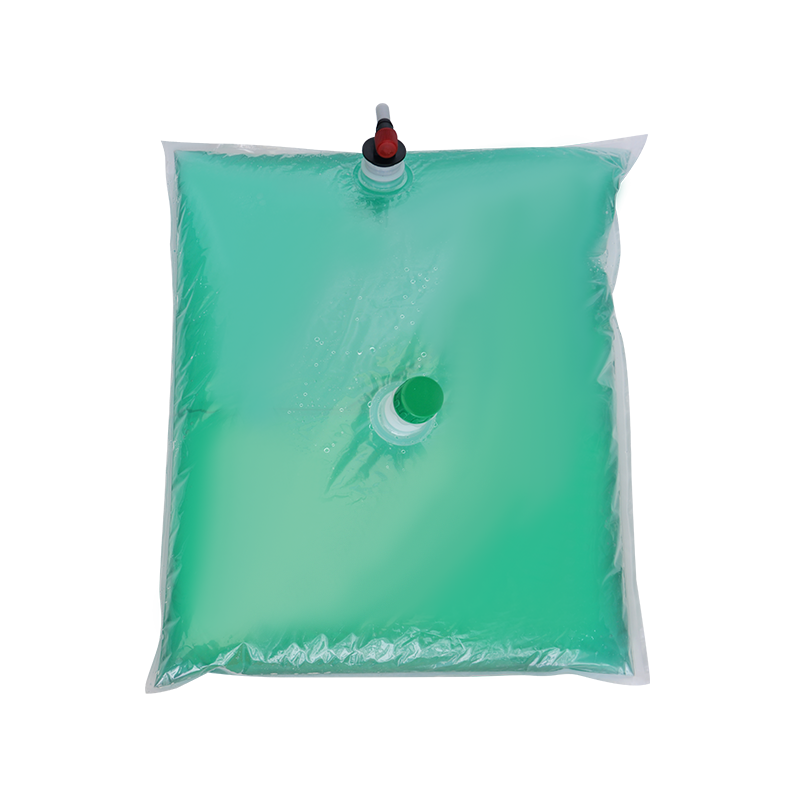

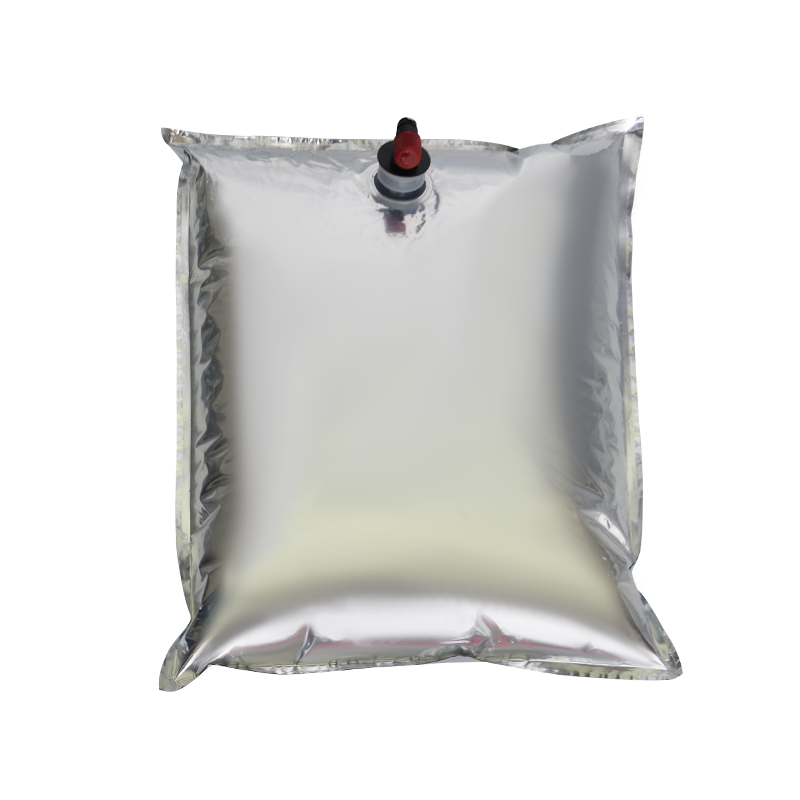

In order to meet the needs of different industries and customers, the bag-in-box liquid valve system also provides a wealth of customized services. From the selection of inner bag materials, the type and specifications of valves, to the design and printing of outer boxes, they can be flexibly adjusted according to the specific requirements of customers. This customized service not only improves the market competitiveness of the product, but also brings customers a more intimate and professional service experience.

The bag-in-box liquid valve system has significant advantages in environmental protection due to its lightweight and easy recycling characteristics. Compared with traditional glass bottles or all-plastic packaging, the bag-in-box design significantly reduces the consumption of packaging materials and the generation of waste. At the same time, since both the inner bag and the outer box can be recycled, this packaging form is also in line with the concept of sustainable development.

In the storage, transportation and distribution of liquid products, the bag-in-box liquid valve system shows the characteristics of efficiency and convenience. Its built-in valve system makes it easy and quick to take the liquid, and can be opened and closed quickly without additional tools. Due to the good flexibility and pressure resistance of the packaging material, the bag-in-box can also store more liquid products in a limited space, improving the efficiency of transportation and storage.

Safety is an important link that cannot be ignored in the packaging of liquid products. The bag-in-box liquid valve system ensures the safety and stability of liquids during storage and transportation by adopting a multi-layer composite inner bag and a high-precision valve design. The high barrier performance of the inner bag effectively prevents the penetration of oxygen, moisture and microorganisms, while the sealing and durability of the valve ensure the purity and safety of the liquid product. This safe and reliable design provides a strong guarantee for the long-term storage and transportation of liquid products.

Bag-in-box liquid valve technology is gradually changing the landscape of liquid product packaging with its unique technological innovation and significant advantages. With the continuous advancement of technology and the continuous expansion of the market, this technology will play a more important role in the future and bring more innovation and changes to the industry.

English

English русский

русский