In the medical, pharmaceutical and biotechnology industries, the demand for aseptic packaging is growing, and higher requirements are placed on the performance, capacity and safety of packaging materials. As a large-capacity, high-standard aseptic packaging solution, the 220L aseptic bag is occupying an increasingly important position in the industry with its unique professional advantages.

Sterility is one of the most basic and important requirements for medical packaging. The 220L aseptic bag is treated by strict irradiation sterilization or gas sterilization process to ensure that the space inside the bag meets the medical grade sterility standard. This treatment method can not only effectively kill microorganisms such as bacteria and viruses, but also maintain the stability and chemical inertness of the packaging material, and avoid contamination of medical supplies by residues generated during the sterilization process. Therefore, medical supplies packaged in 220L aseptic bags can maintain their sterility for a long time, providing solid protection for the health and safety of patients.

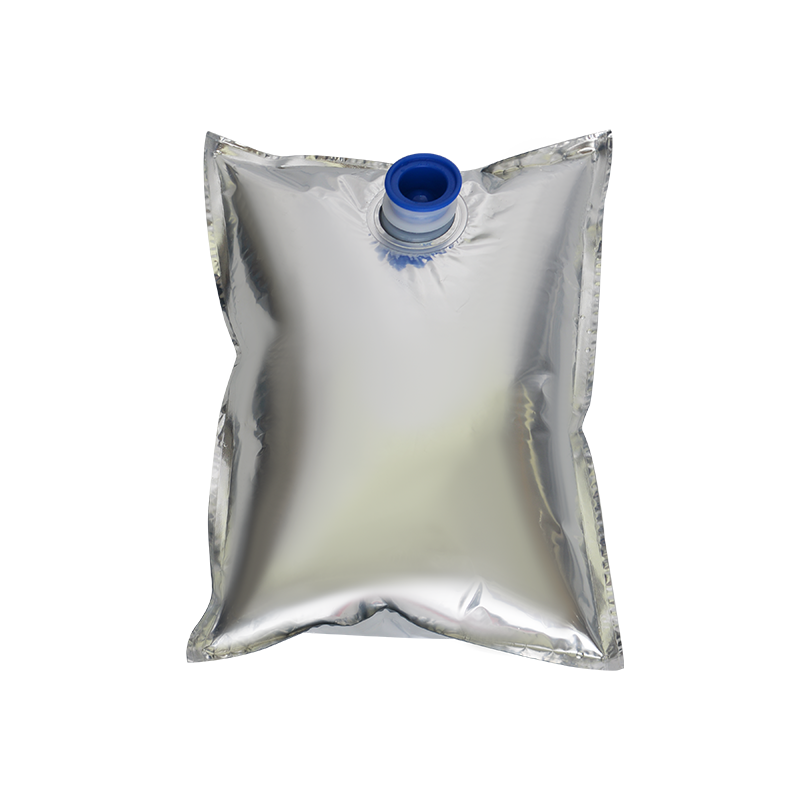

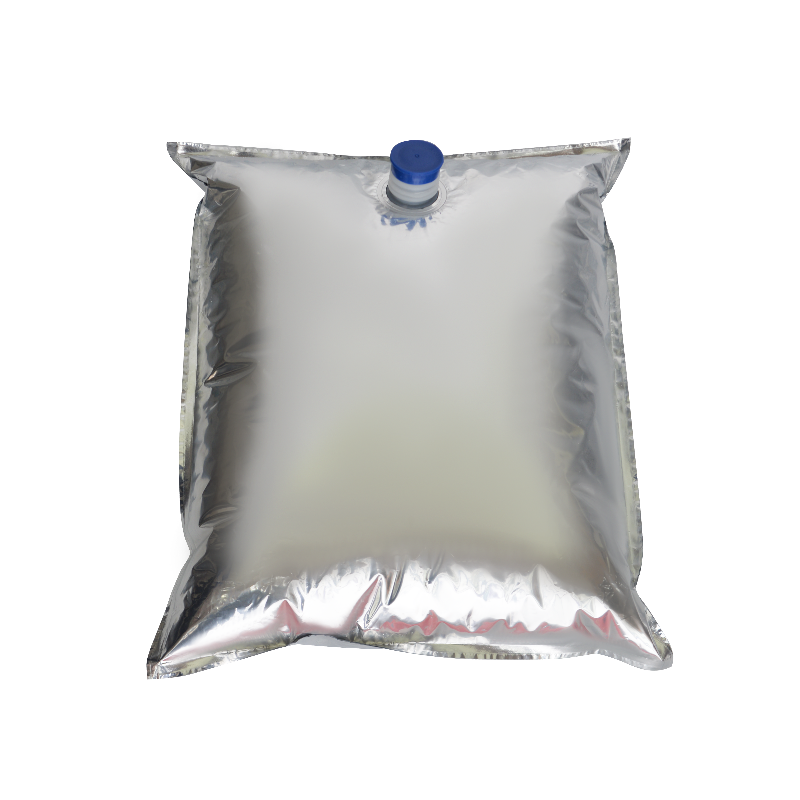

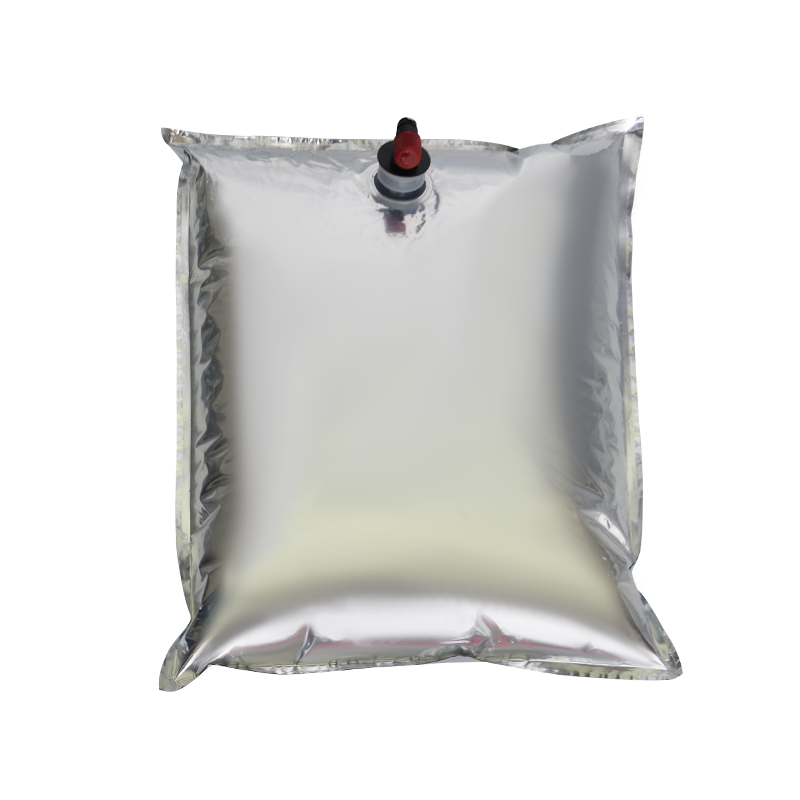

Compared with traditional small-capacity aseptic packaging, the biggest highlight of the 220L aseptic bag is its large-capacity design. This design significantly increases the single load volume, which not only reduces the use of packaging materials and reduces packaging costs, but also improves logistics efficiency and reduces the number of transportation times and transportation costs. For medical supplies that need to be stored and transported in large quantities, such as biological products, vaccines, surgical instruments, etc., 220L sterile bags are undoubtedly a more efficient and economical choice.

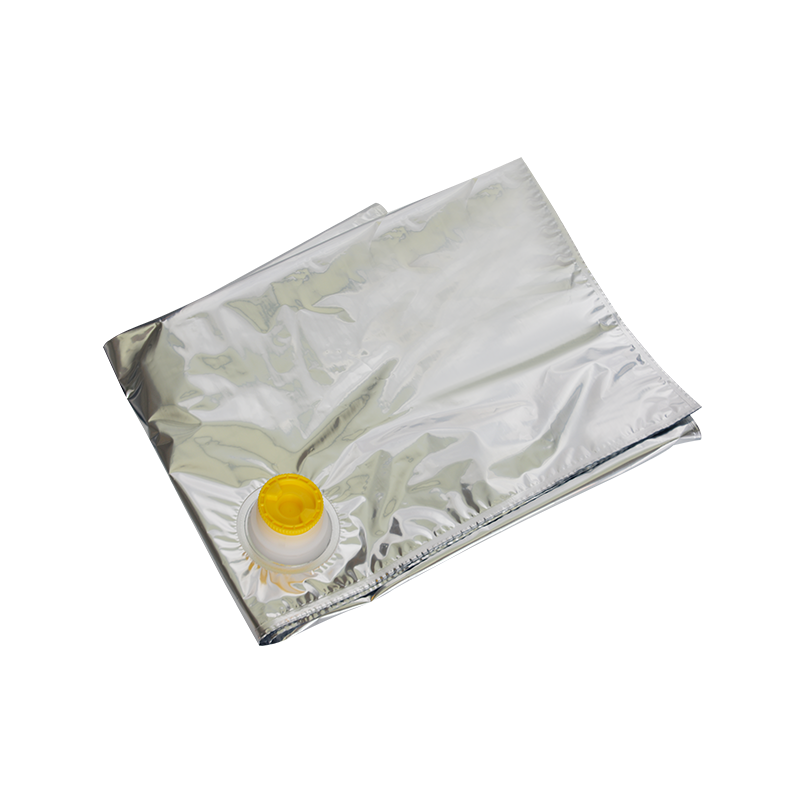

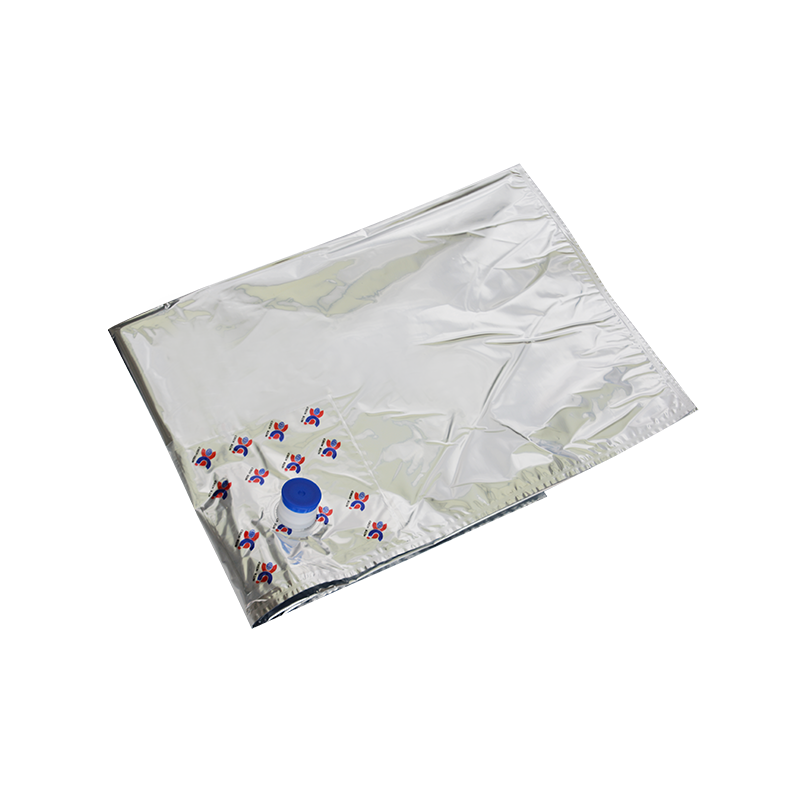

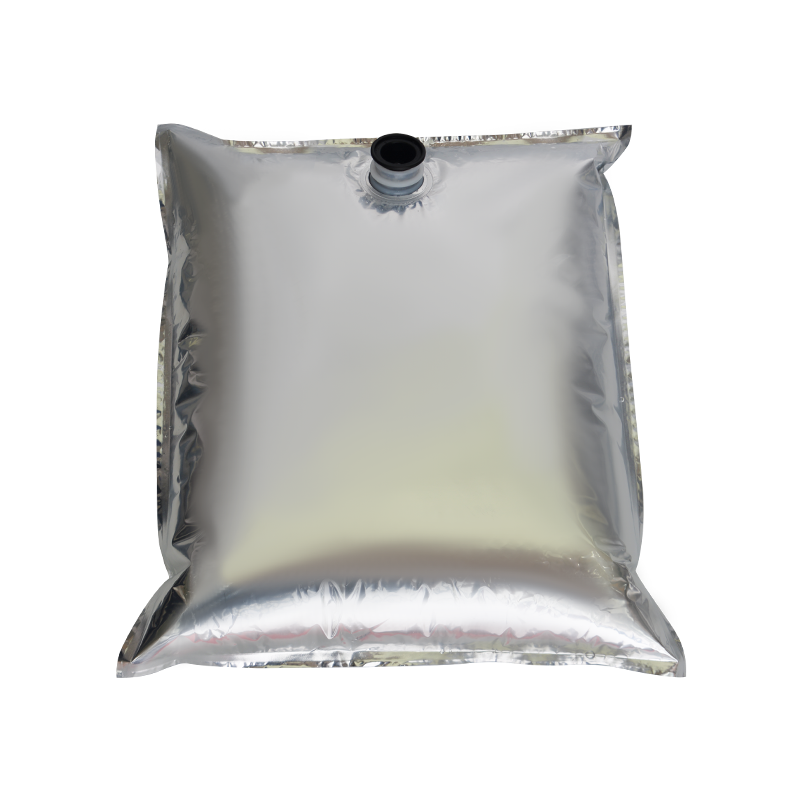

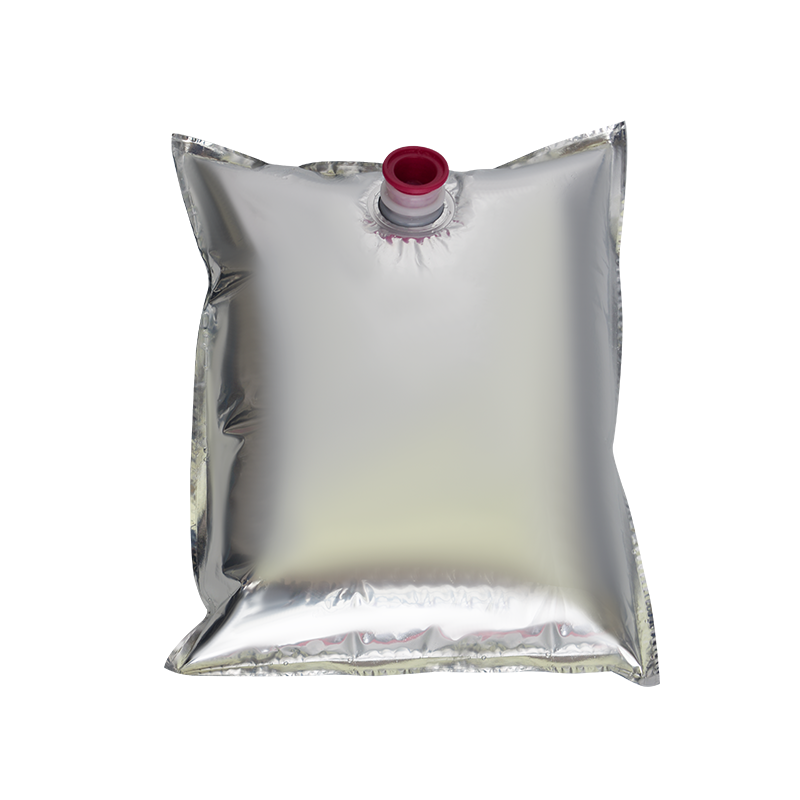

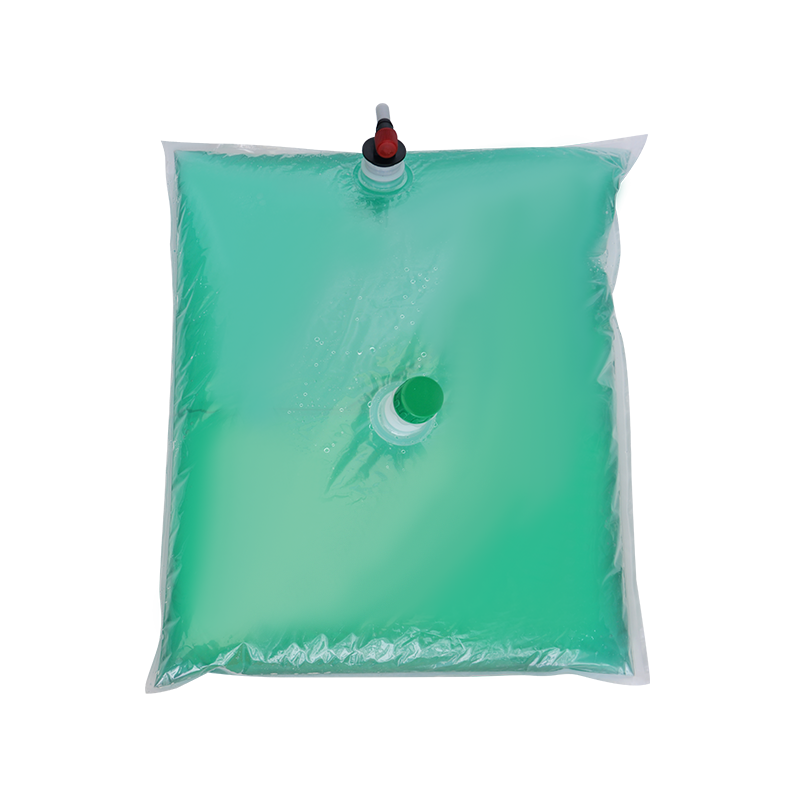

220L sterile bags are usually made of high-strength and high-toughness medical-grade materials, such as medical-grade polyethylene or polyamide. These materials not only have good sealing properties, which can effectively prevent external contamination from entering the bag, but also have chemical corrosion resistance and low temperature resistance. Even in extreme environments, the stability and integrity of the packaging materials can be maintained to ensure the safety and integrity of medical supplies. Sterile bags are also carefully designed to ensure that they are not easily damaged, deformed or leaked during transportation and storage, providing all-round protection for medical supplies.

In today's society, environmental protection and sustainability have become the focus of attention in all walks of life. 220L sterile bags fully consider environmental factors in both material selection and production process. The use of recyclable or biodegradable medical-grade materials reduces pollution to the environment; at the same time, energy consumption and waste generation are reduced through optimized production processes and technological innovation. This environmentally friendly design concept not only meets the requirements of the current global environmental protection trend, but also contributes to the sustainable development of the medical industry.

The 220L sterile bag has shown strong competitiveness and broad application prospects in the field of medical packaging with its professional advantages such as sterility assurance, large-capacity design, physical properties and durability, environmental protection and sustainability, and a wide range of application scenarios. With the continuous advancement of medical technology and the deepening of global medical cooperation, the 220L sterile bag will play a more important role in the future and contribute more to improving the quality and safety level of global medical care.

English

English русский

русский