In the fast-paced modern life, the storage, transportation and distribution efficiency of liquid products have become the focus of attention of all walks of life. From food and beverages to chemical raw materials, from agricultural irrigation to personal care, the demand for efficient, safe and environmentally friendly packaging solutions is growing. In this context, a packaging form called "Bag-in-Box" has rapidly emerged worldwide with its unique advantages and has become a packaging solution favored by many industries.

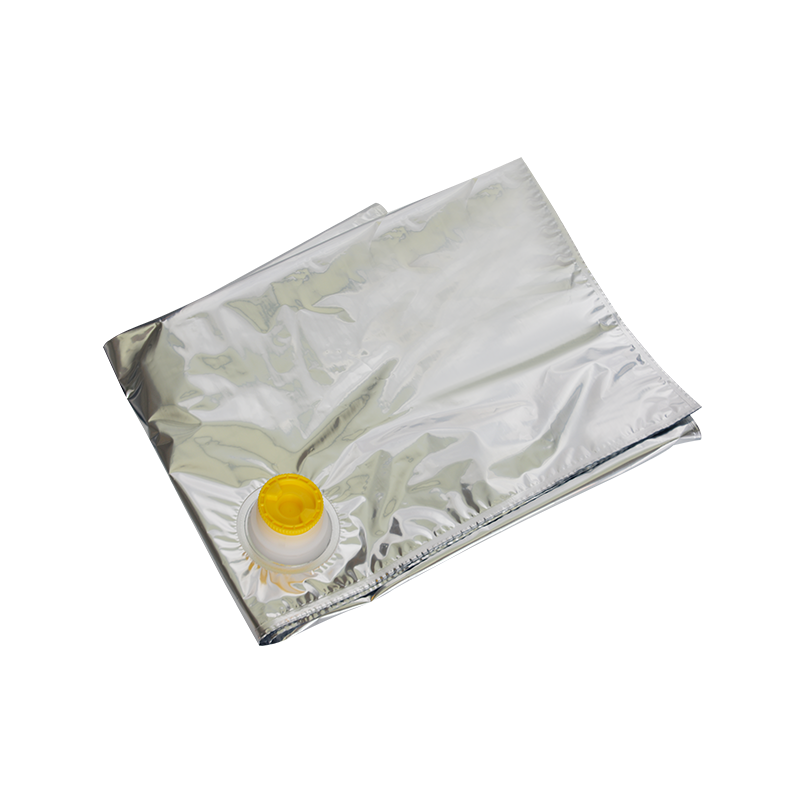

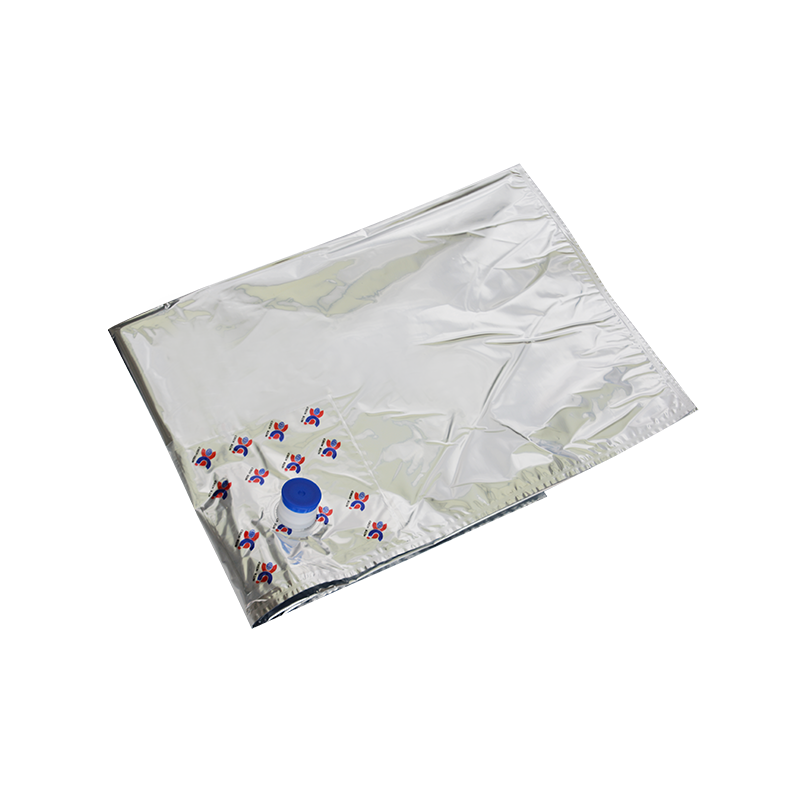

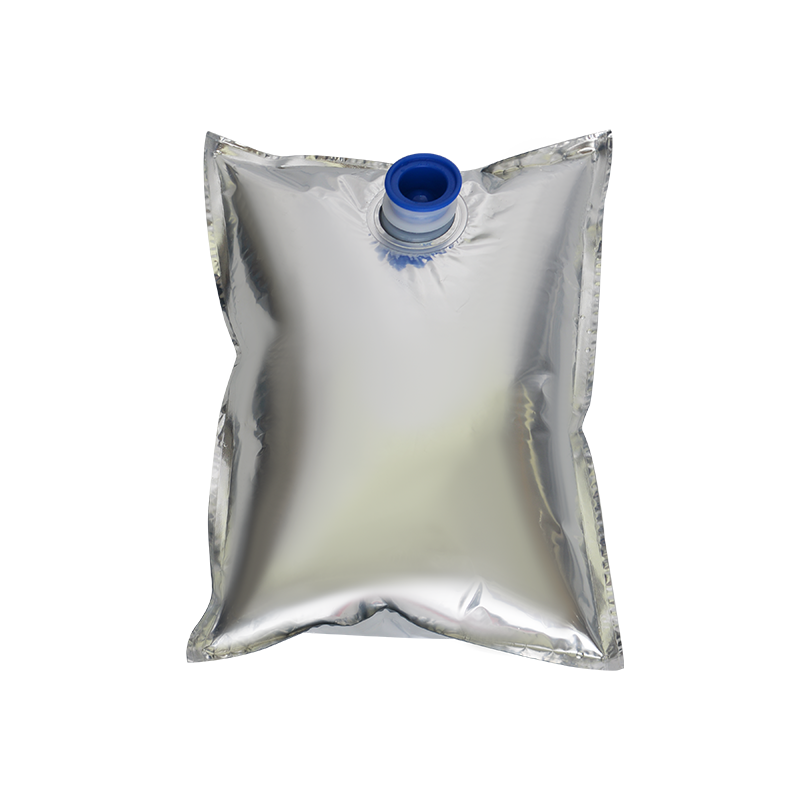

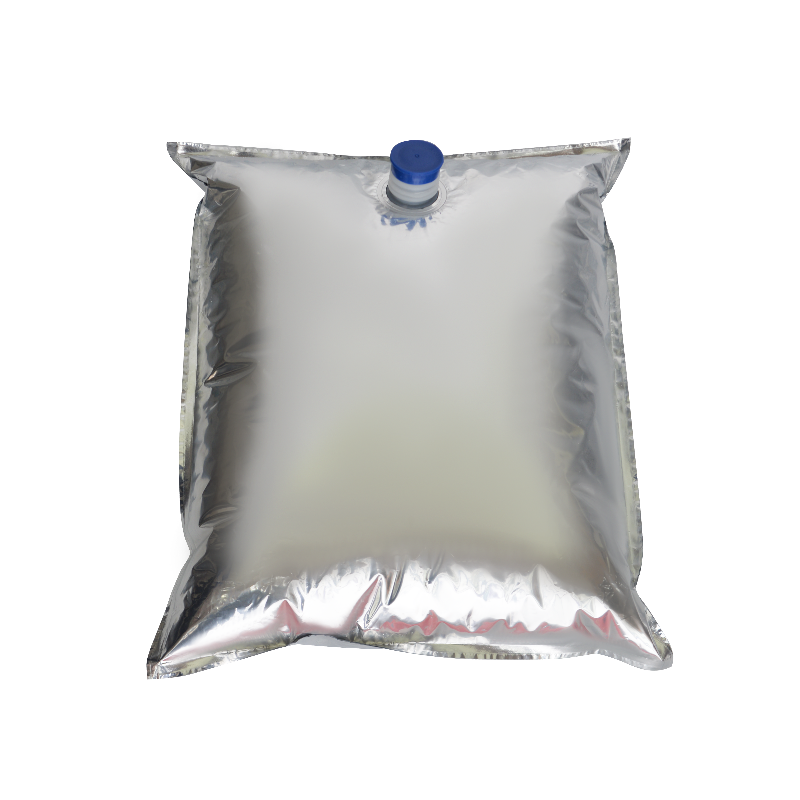

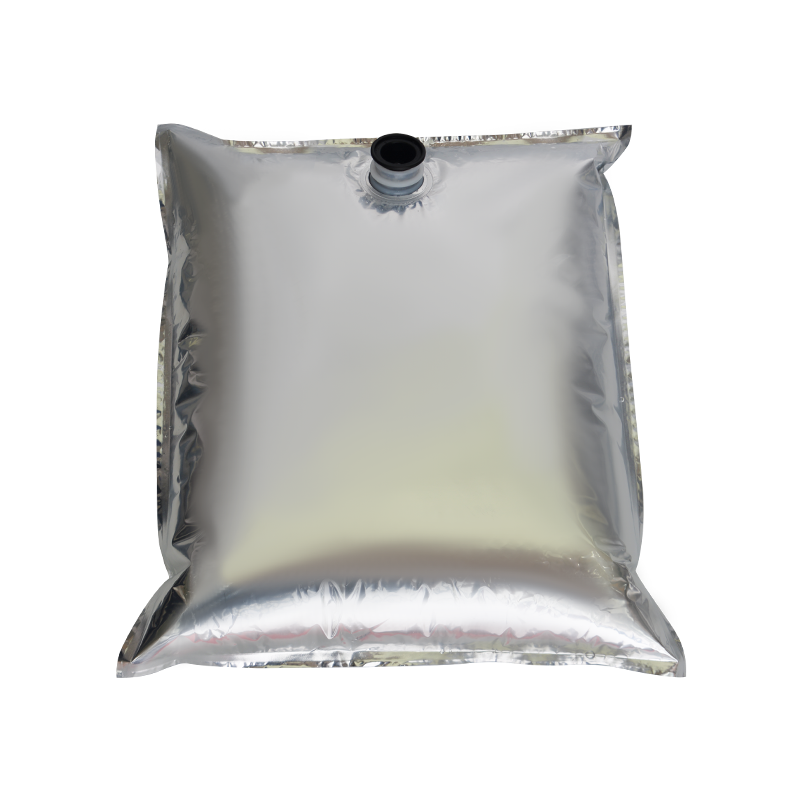

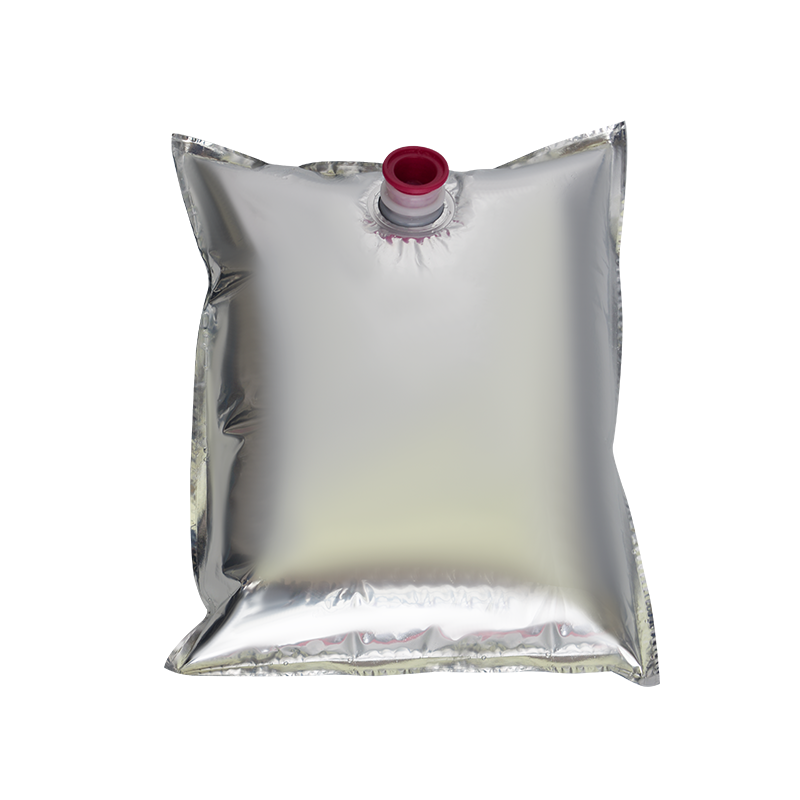

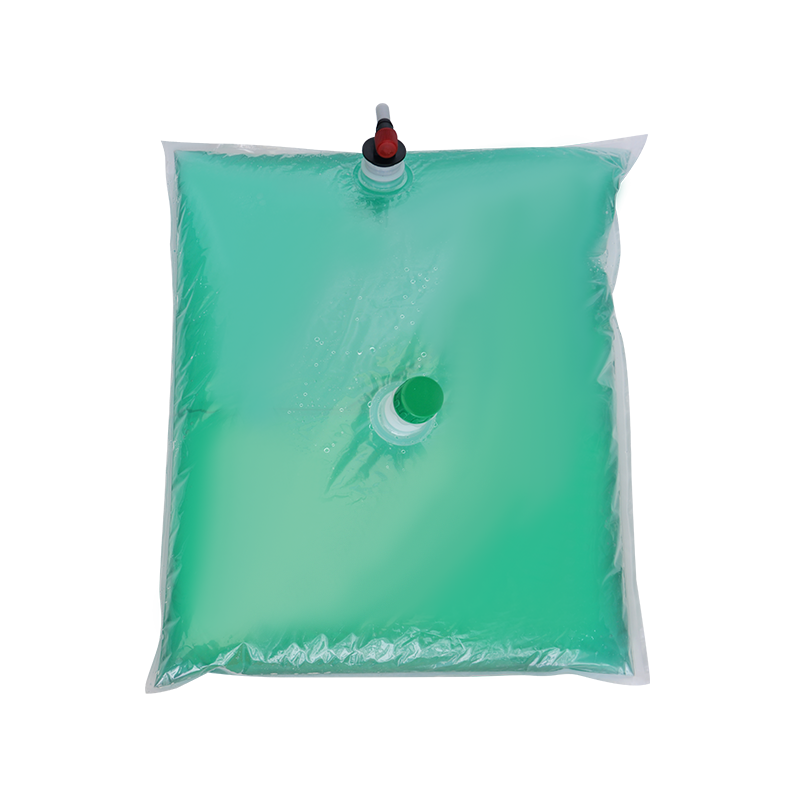

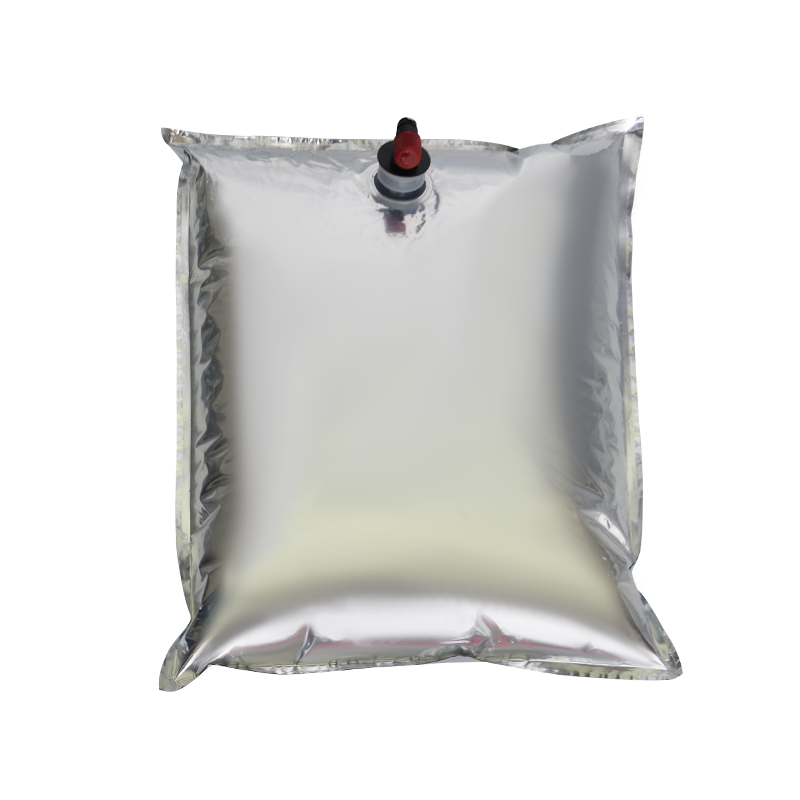

Bag-in-Box is a packaging system that places a flexible plastic bag in a hard shell. Its core is a flexible inner bag made of multi-layer composite materials, which usually include polyethylene (PE), nylon (NY), ethylene-vinyl alcohol copolymer (EVOH), etc., to provide barrier properties to prevent the influence of external factors such as oxygen, moisture, and ultraviolet rays on the contents. The hard shell is mostly made of corrugated cardboard or plastic, providing structural support and protection, and is easy to stack, store and transport.

The working principle of this packaging is simple and efficient: the inner bag is connected to the dispensing system through a special valve or adapter. The user only needs to open the valve to safely and hygienically dispense the liquid product into the required container through a pump or gravity. After use, the valve is closed to effectively prevent air from entering and extend the shelf life of the product.

Advantages of Bag-in-Box

Cost-effectiveness: Compared with traditional bottles or cans, Bag-in-Box has lower packaging costs because it reduces material use and space occupation during transportation, reducing overall logistics costs. At the same time, the large-capacity design reduces the need for frequent packaging changes and improves work efficiency.

Environmentally friendly and sustainable: The lightweight design and recyclable materials (such as cardboard, PE, etc.) of Bag-in-Box make it highly environmentally friendly. Reducing the use of plastics and reducing waste generation is in line with the global pursuit of sustainable development.

Fresh-keeping performance: The multi-layer composite inner bag provides gas barrier properties, effectively preventing oxidation and deterioration, and extending the shelf life of products. It is especially suitable for oxygen-sensitive products such as juice, wine, condiments, etc.

Convenience and flexibility: The flexible inner bag under the protection of the hard shell is easy to carry and handle, and is suitable for storage spaces of various sizes. In addition, the capacity can be customized according to different needs to meet the needs of different application scenarios.

Hygiene and safety: The disposable valve and adapter design, as well as the sealing of the inner bag, ensure the hygienic safety of the product before and after opening, and reduce the risk of cross contamination.

Bag-in-Box is widely used in the food and beverage industry, especially in the packaging of liquid foods such as juice, wine, beer, and cooking oil. In addition, it also shows great potential in the fields of agriculture, chemicals, personal care, and medicine, such as the packaging of pesticides, lubricants, shampoos, disinfectants and other products.

English

English русский

русский