In the food and beverage industry, aseptic packaging technology is increasingly becoming a key factor in ensuring product safety, extending shelf life, and improving consumer experience. Against this backdrop, aseptic bag-in-box (BIB), as an innovative packaging form, has rapidly emerged with its unique advantages and has become the first choice for many manufacturers and consumers.

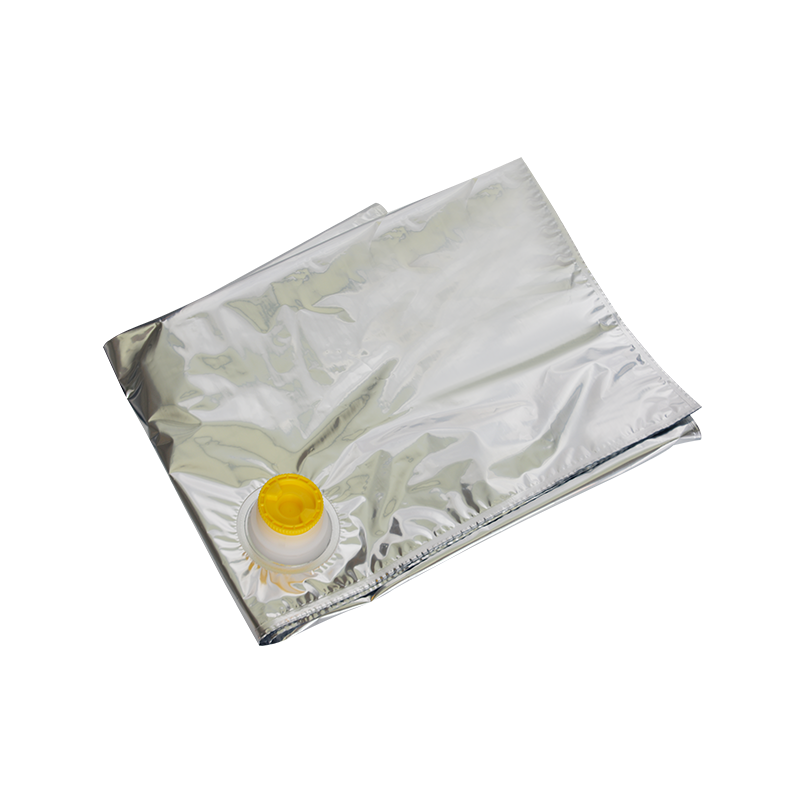

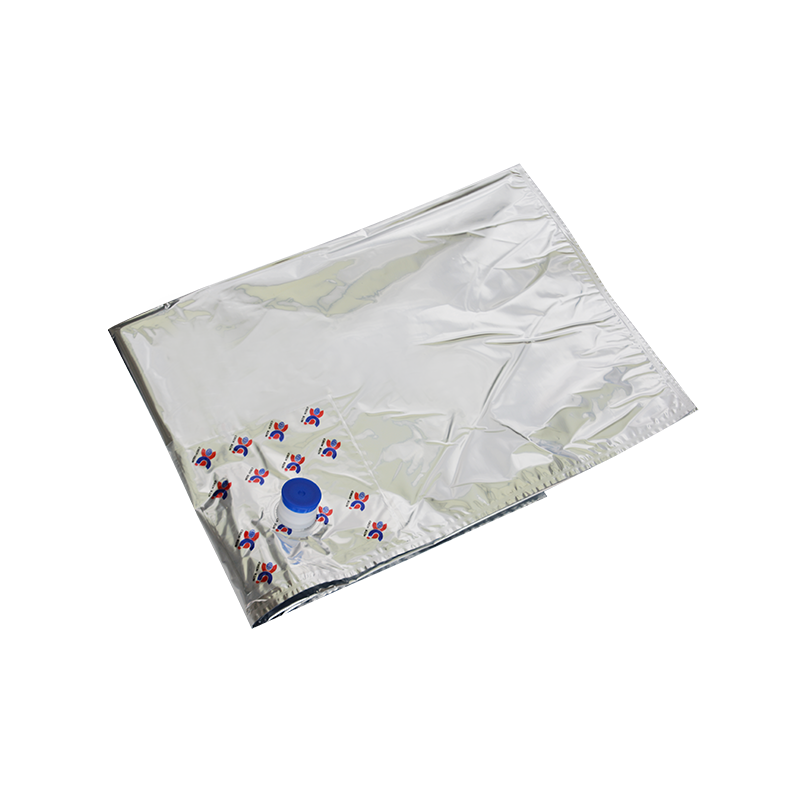

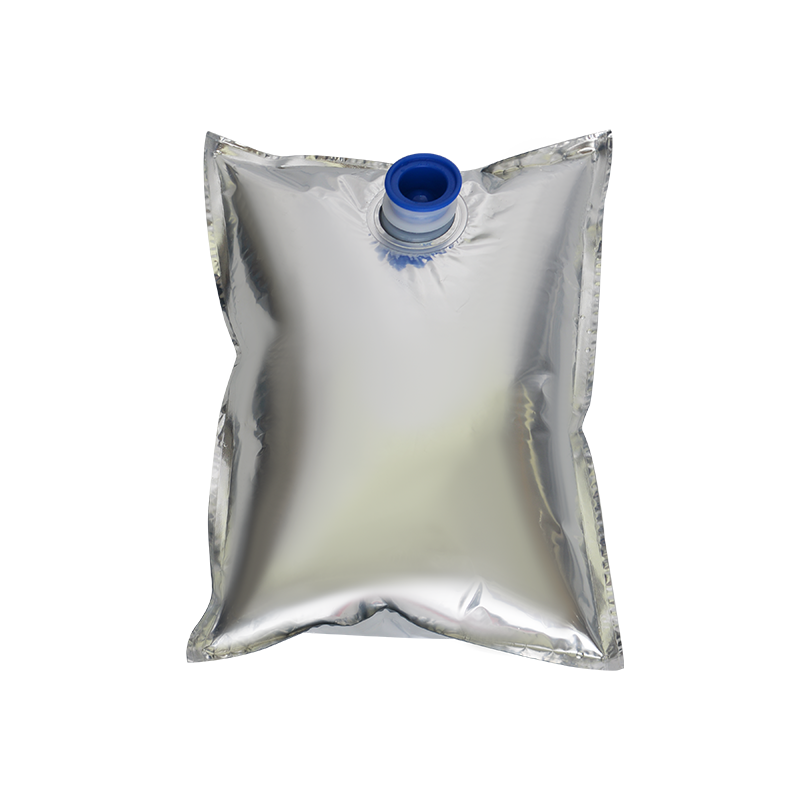

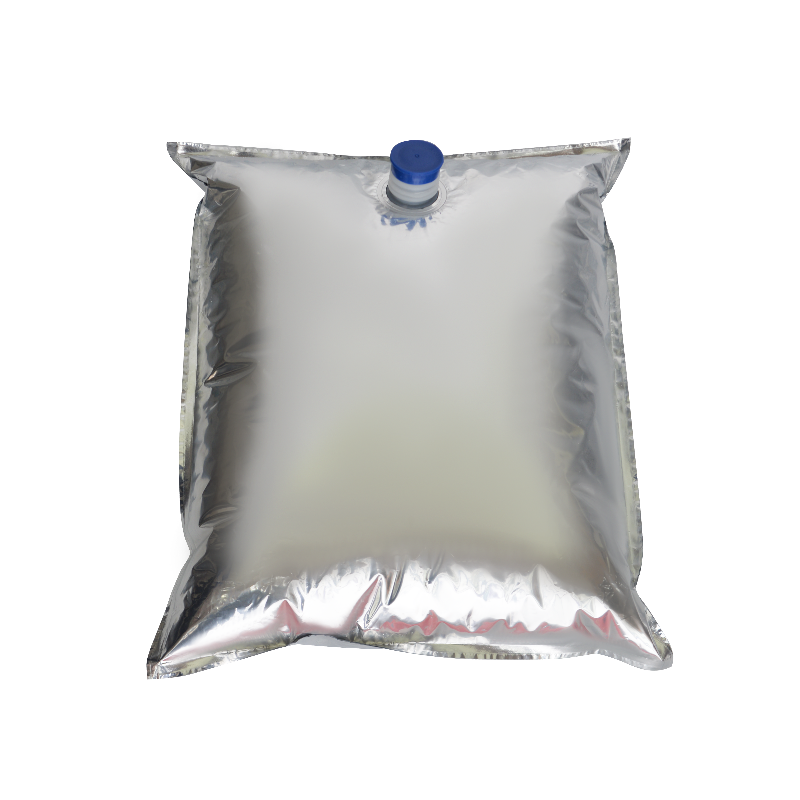

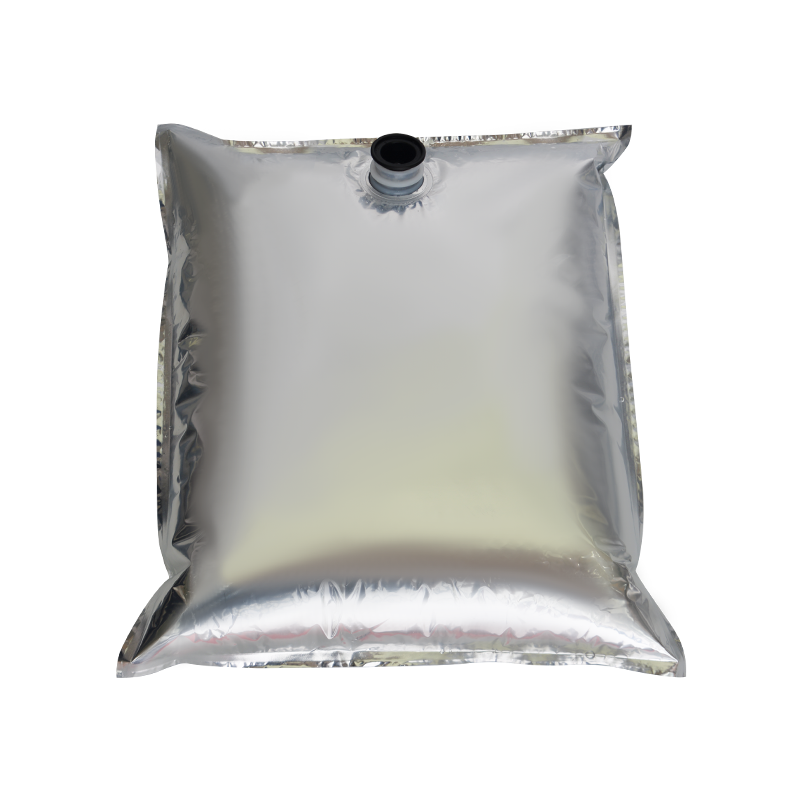

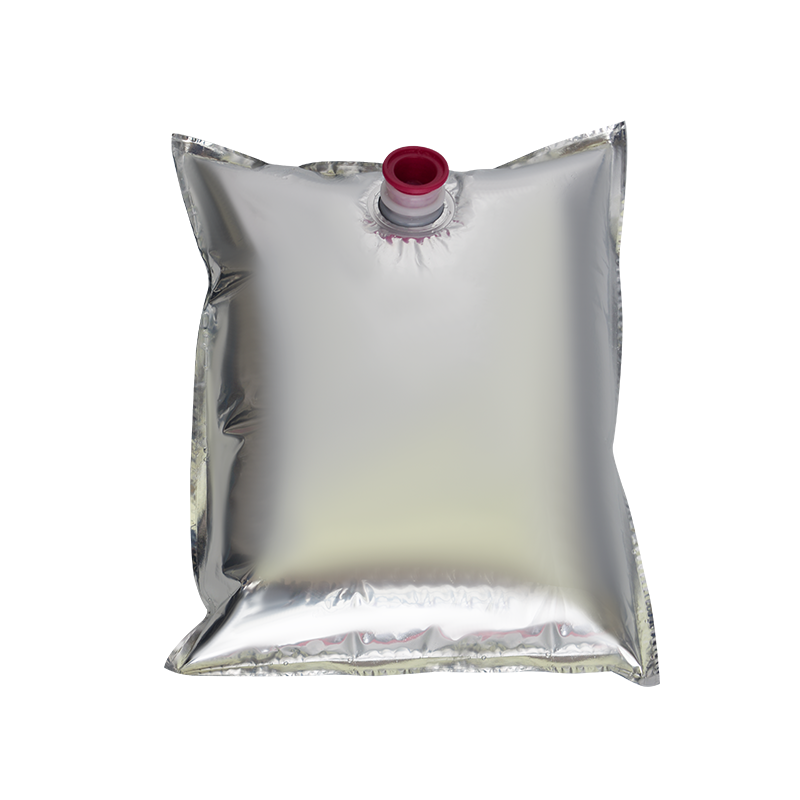

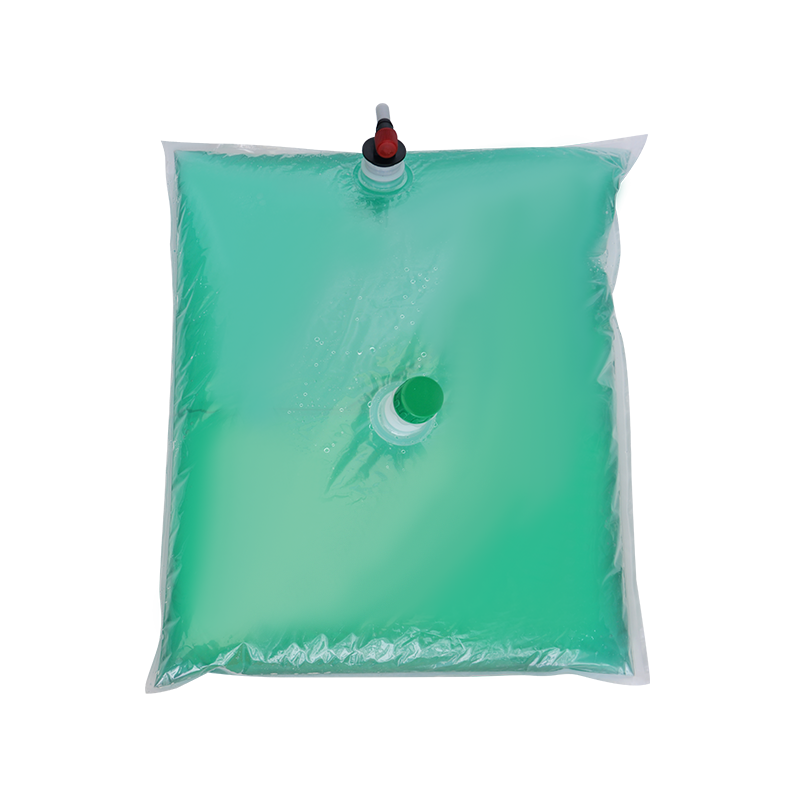

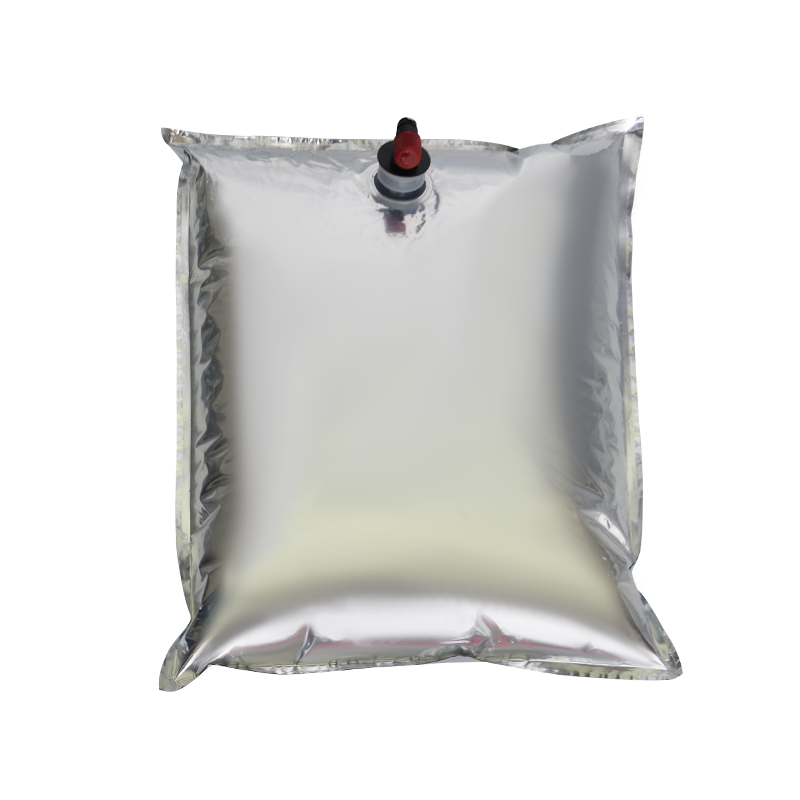

Aseptic bag-in-box is a packaging system that combines flexible packaging materials (such as polyethylene PE and polyethylene terephthalate PET) with advanced aseptic technology. The system ensures that the product is free from microbial contamination during filling, sealing and transportation through a series of rigorous processes. The core is to use an aseptic environment for filling and be equipped with a special aseptic valve so that it can be taken without destroying the integrity of the package.

Advantages of aseptic bag-in-box

Efficient aseptic guarantee: Aseptic bag-in-box uses advanced aseptic technology to ensure that the product remains sterile throughout the supply chain, effectively extending the shelf life of the product and reducing the loss caused by microbial contamination.

Flexibility and convenience: The design of aseptic bag boxes enables them to accommodate different volumes and types of liquids, such as juice, milk, oil, wine, etc. Its light weight and easy stacking make storage and transportation more efficient. In addition, the design with valves makes product access more convenient and reduces waste.

Environmental protection and sustainability: Compared with traditional rigid packaging, aseptic bag boxes use less materials, and most of them are recyclable materials, which helps to reduce garbage generation and conforms to the current environmental protection trend.

Cost-effectiveness: Aseptic bag boxes have relatively low manufacturing costs, and due to their efficient transportation and storage capabilities, they can further reduce logistics costs and bring higher economic benefits to manufacturers.

Application of aseptic bag boxes in the food and beverage industry

Juice and dairy products: Aseptic bag boxes occupy an important position in the juice and dairy market due to their excellent aseptic protection and convenience. Manufacturers can use their extended shelf life characteristics to sell products to more distant markets.

Alcoholic products: As consumers' requirements for convenience and freshness of alcoholic products such as wine increase, aseptic bag boxes are gradually becoming a new choice for alcoholic packaging. It not only maintains the original flavor of the wine, but also provides consumers with a more flexible way of taking it.

Edible oil and condiments: Aseptic bag boxes are also widely used in the field of edible oil and condiments. Its oil resistance and sealing performance ensure the freshness and safety of the product, satisfying consumers' pursuit of high-quality life.

Other foods: Aseptic bag boxes are also suitable for the packaging of foods such as ketchup, concentrated juice, and syrup. Its flexible volume and easy storage characteristics make these foods more convenient in processing, transportation, and sales.

English

English русский

русский