In the modern food industry, aseptic packaging has become an important means to ensure food safety, extend shelf life and enhance product value. Aseptic packaging bags are the core carrier of this technology, and their importance is self-evident.

The core of aseptic packaging bags lies in their aseptic packaging technology, which is to package sterilized food in a sterile environment and seal it in a sterilized container. This process needs to be carried out under an environment with strict control of microbial contamination to ensure that the food is not contaminated by bacteria after packaging, thereby extending the shelf life of the food.

Sterilization is the first step in aseptic packaging, usually using high-temperature sterilization or chemical sterilization methods. High-temperature sterilization kills microorganisms in food by heating it to a certain temperature and keeping it for a period of time. Chemical sterilization uses chemical disinfectants to disinfect the surface of food.

A sterile environment is the key to aseptic packaging. During the packaging process, it is necessary to ensure that the entire operating area, packaging materials and the food itself are in a sterile state. This is usually achieved through equipment such as high-efficiency air filters, ultraviolet disinfection and sterile operating tables.

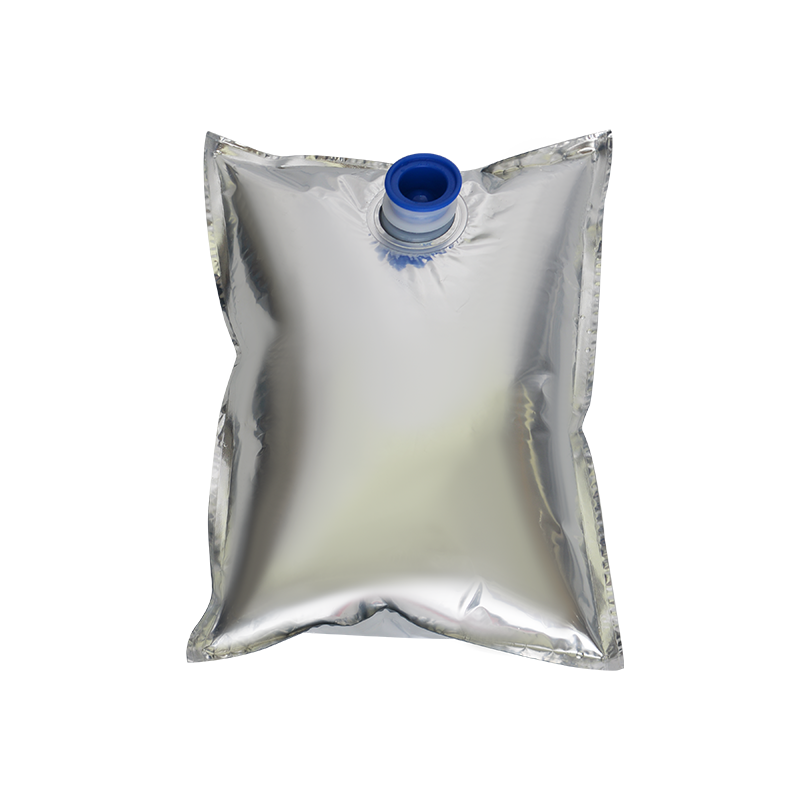

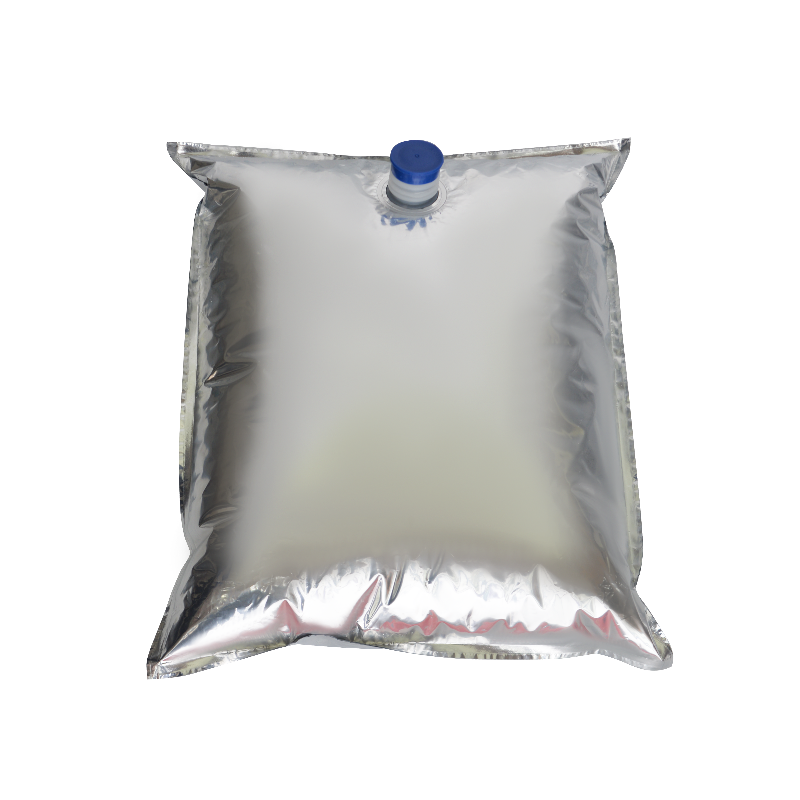

Sealing is the last step of aseptic packaging. Sterilized food is packed into pre-sterilized packaging bags, and the mouth of the packaging bag is sealed using special sealing technology. This step requires ensuring that the inside of the packaging bag is completely isolated from the outside to prevent re-contamination by microorganisms.

The material selection of aseptic packaging bags is crucial to their performance. High-quality materials not only provide good barrier properties, but also ensure that the taste and nutritional value of food remain unchanged for a long time.

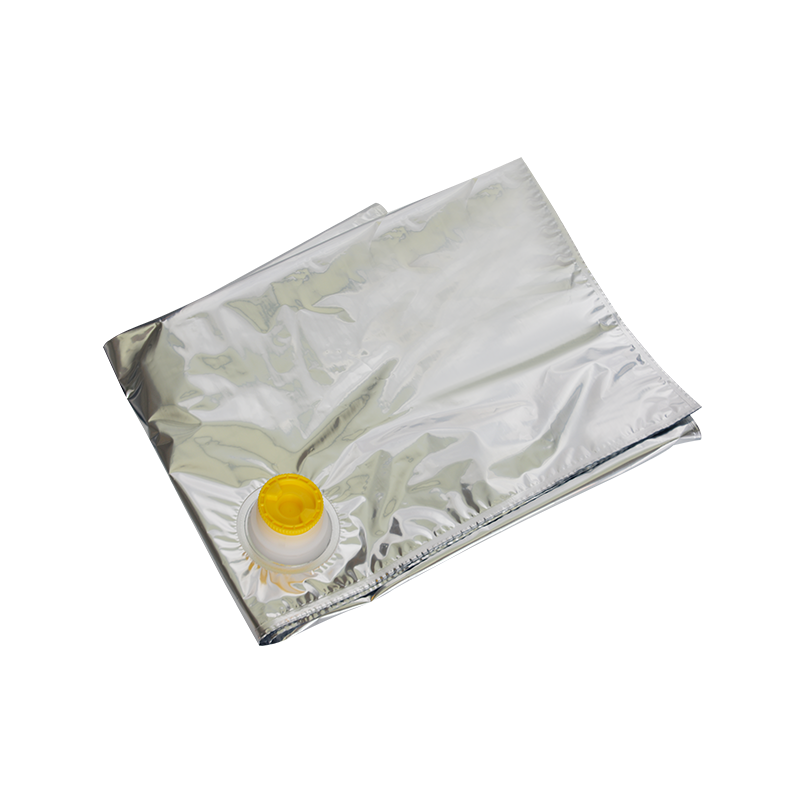

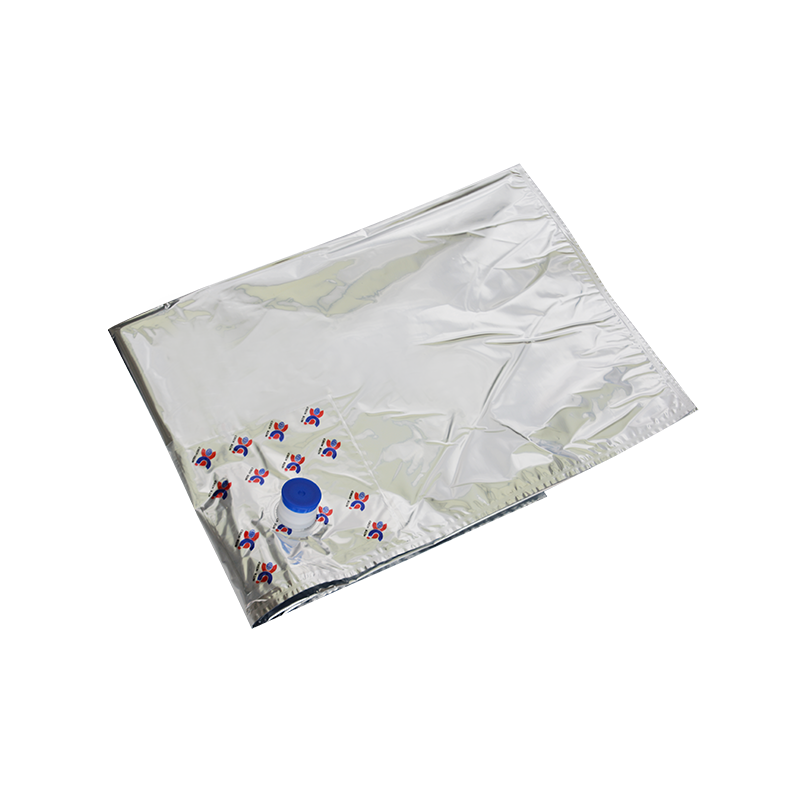

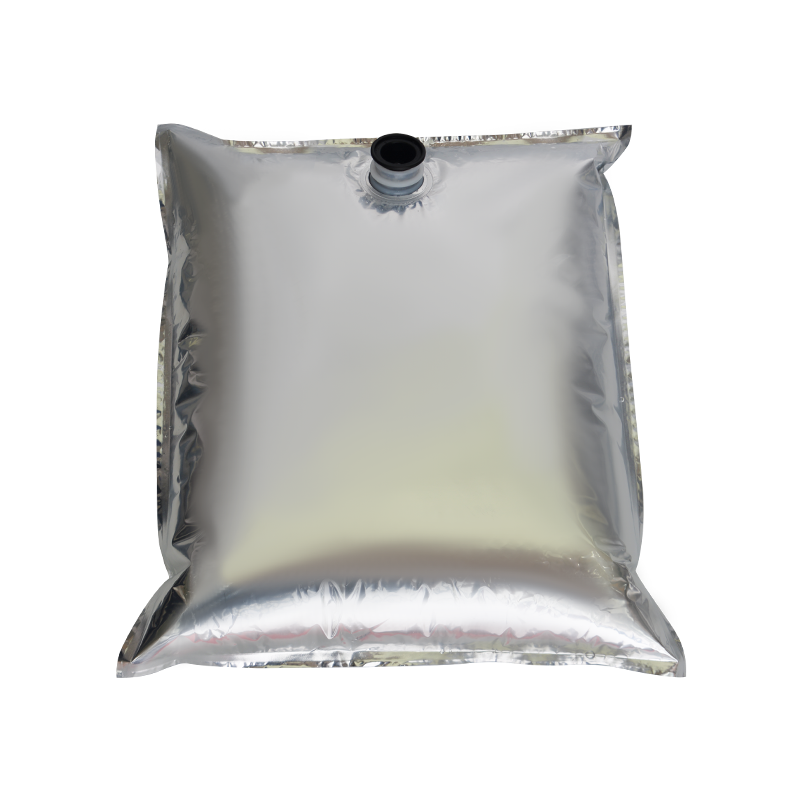

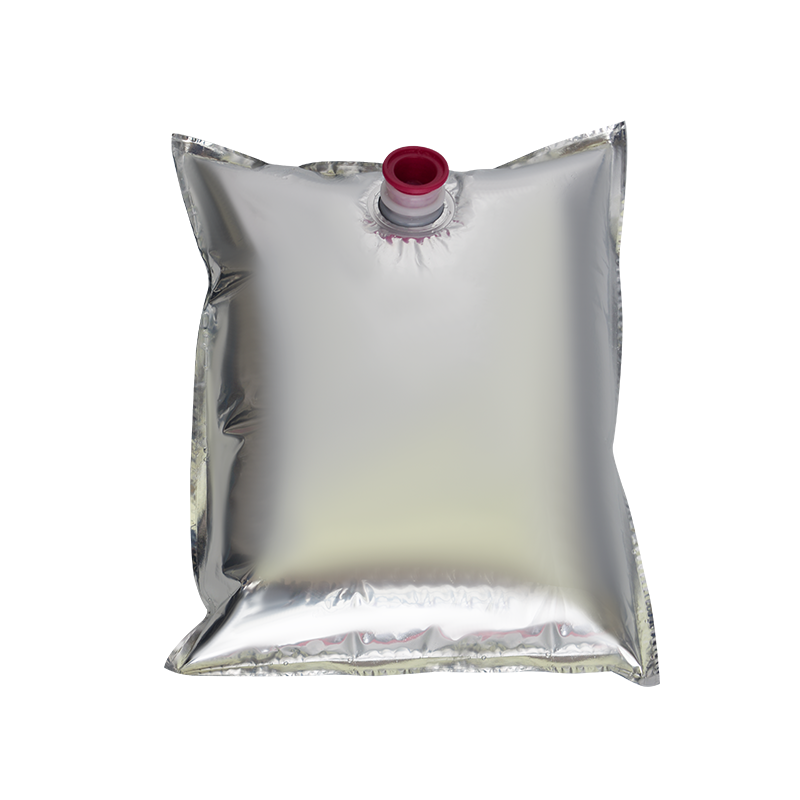

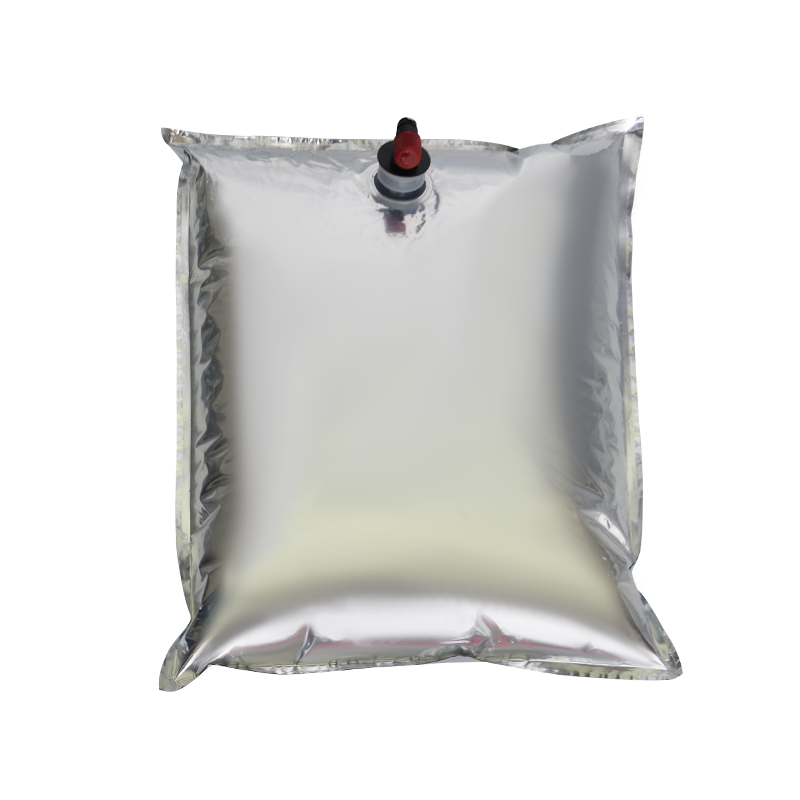

High-barrier materials are the main components of aseptic packaging bags. These materials usually have low oxygen permeability and moisture permeability, which can effectively prevent oxygen and moisture from entering the inside of the packaging bag, thereby extending the shelf life of food. Common high-barrier materials include aluminized film, aluminum foil, and multi-layer co-extruded film.

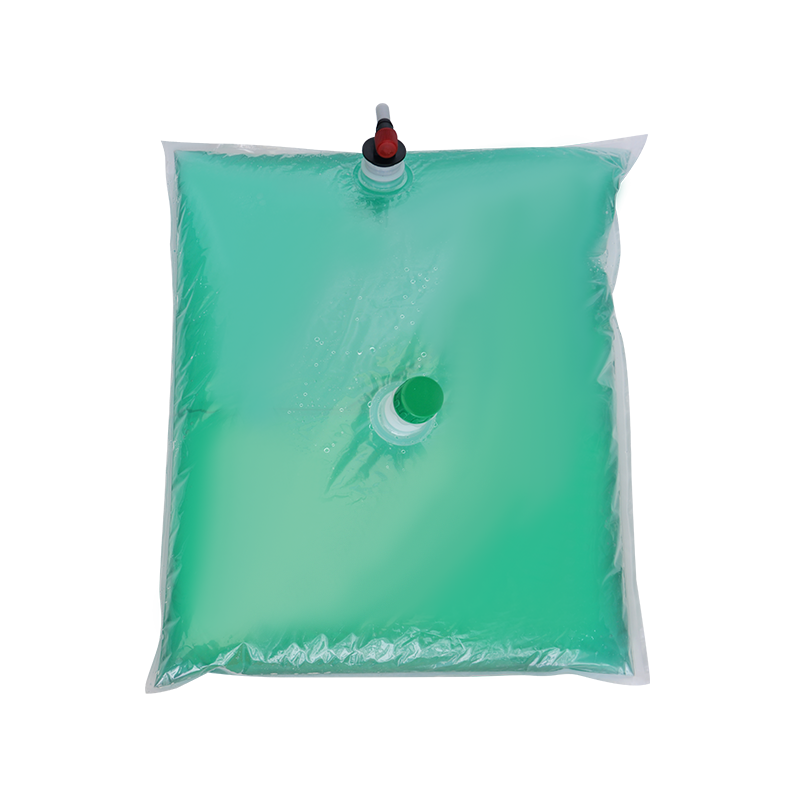

Aseptic packaging bags need to withstand certain pressure and folding during transportation and storage. Therefore, choosing materials that are resistant to folding and pressure is crucial to ensure the integrity of the packaging bag and the safety of the food. Common resistant to folding and pressure materials include polyethylene (PE), polypropylene (PP), and polyester (PET).

With the improvement of environmental awareness, more and more consumers are beginning to pay attention to the environmental performance of aseptic packaging bags. Choosing degradable or recyclable materials can not only reduce environmental pollution, but also enhance the social responsibility of enterprises. Common environmentally friendly materials include biodegradable plastics, paper materials and recyclable plastics.

Aseptic packaging bags are widely used in the packaging of various foods and beverages due to their unique properties. Here are some of the main application areas:

Dairy products are one of the important application areas of aseptic packaging bags. Aseptic packaging can effectively extend the shelf life of dairy products while maintaining their taste and nutritional value. Common aseptic packaging bags for dairy products include milk bags, yogurt bags and cheese packaging.

Juice drinks are also a common application area for aseptic packaging bags. Aseptic packaging can prevent juice from being contaminated by microorganisms during the packaging process, thereby maintaining its freshness and taste. Common aseptic packaging bags for juice drinks include juice bags, pulp bags and concentrated juice packaging.

Condiments such as soy sauce, vinegar and sauces are also often packaged in aseptic packaging bags. Aseptic packaging can effectively prevent condiments from deteriorating during storage while maintaining their flavor and taste.

In addition to the above application areas, aseptic packaging bags are also widely used in the packaging of other foods, such as meat, vegetables, fruits and baked goods, etc. These foods can maintain their freshness and nutritional value under the protection of aseptic packaging, thus meeting the needs of consumers.

English

English русский

русский