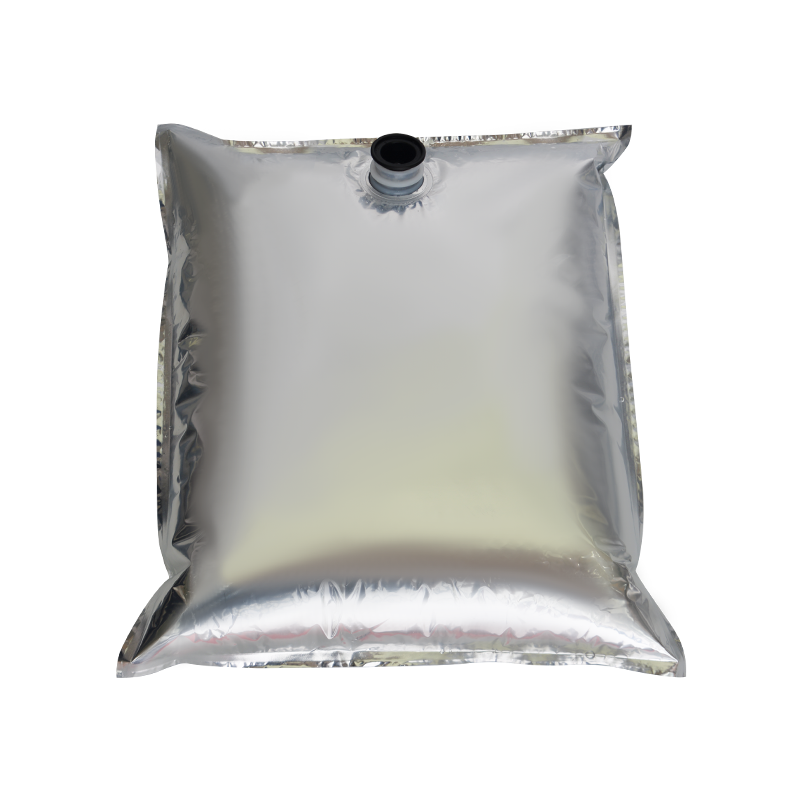

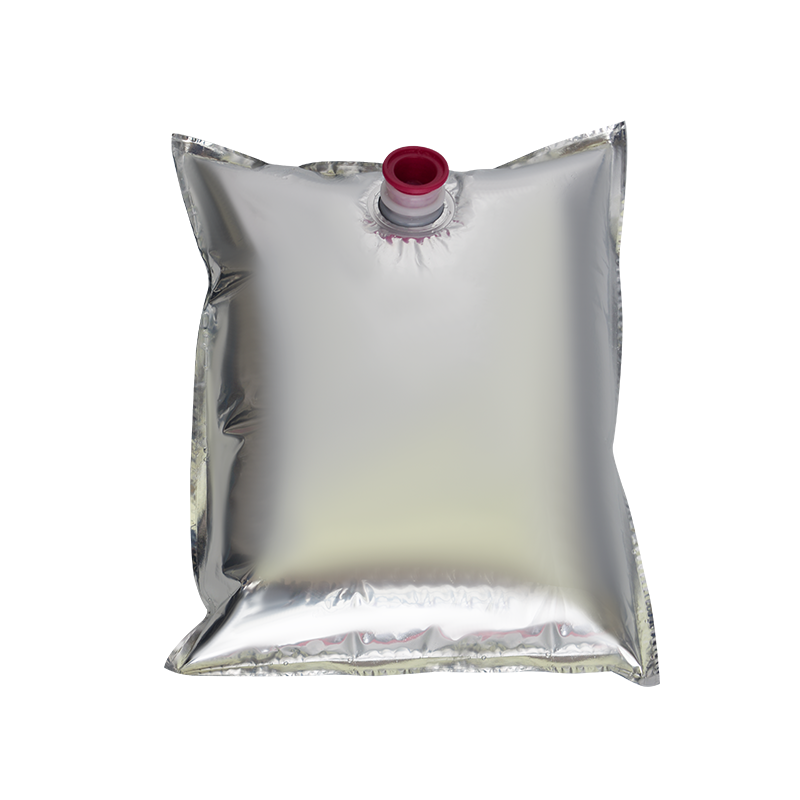

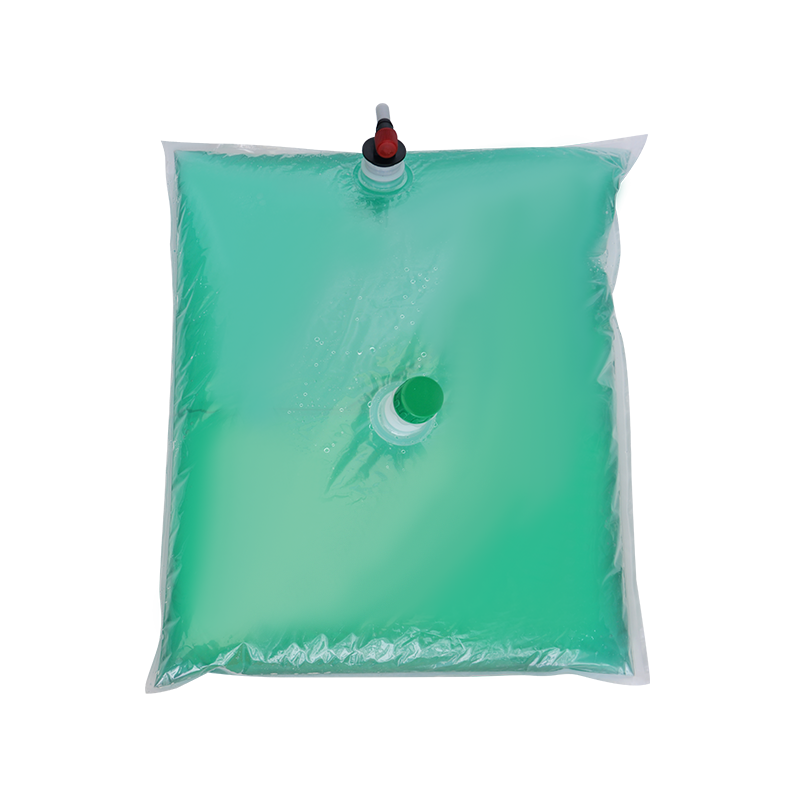

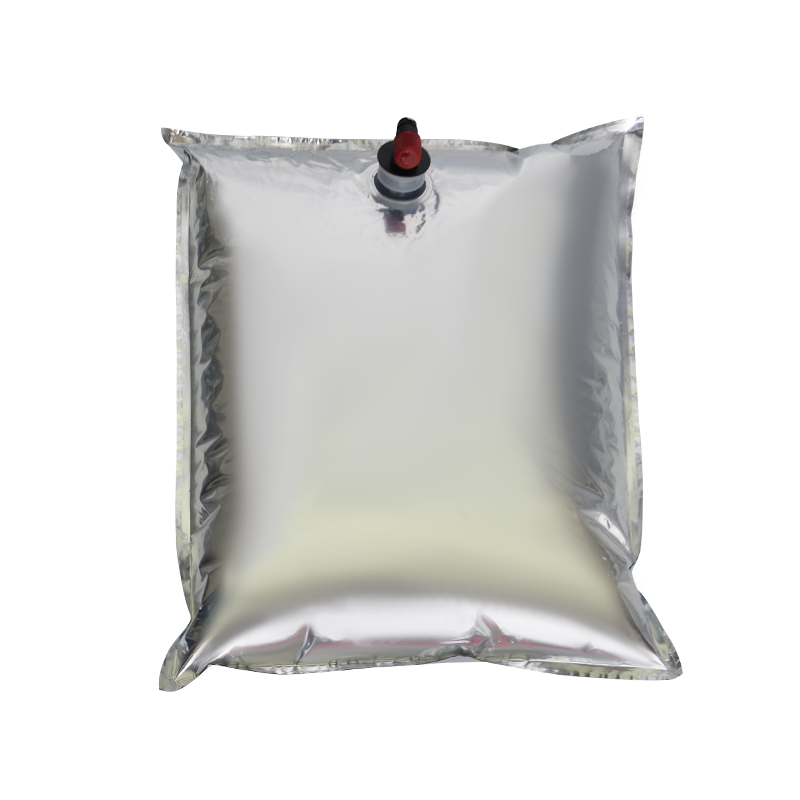

In the field of liquid food packaging, the Aseptic Bag-In-Box system is gradually becoming an important solution for improving product quality, extending shelf life and optimizing user experience. This innovative packaging form is not only widely used in liquid foods such as milk, juice, wine and olive oil, but also shows great potential in the medical, chemical and other industries.

The core advantage of the aseptic bag and box system is that it can effectively maintain the sterility of food, thereby significantly extending the shelf life of the product. Traditional liquid food packaging, such as glass or plastic bottles, typically has a shelf life of only a few days once opened. Food packaged in sterile bags and boxes, such as milk, can maintain a shelf life of up to one month even after opening. This feature is undoubtedly a huge boon for home users, the catering industry and food delivery services.

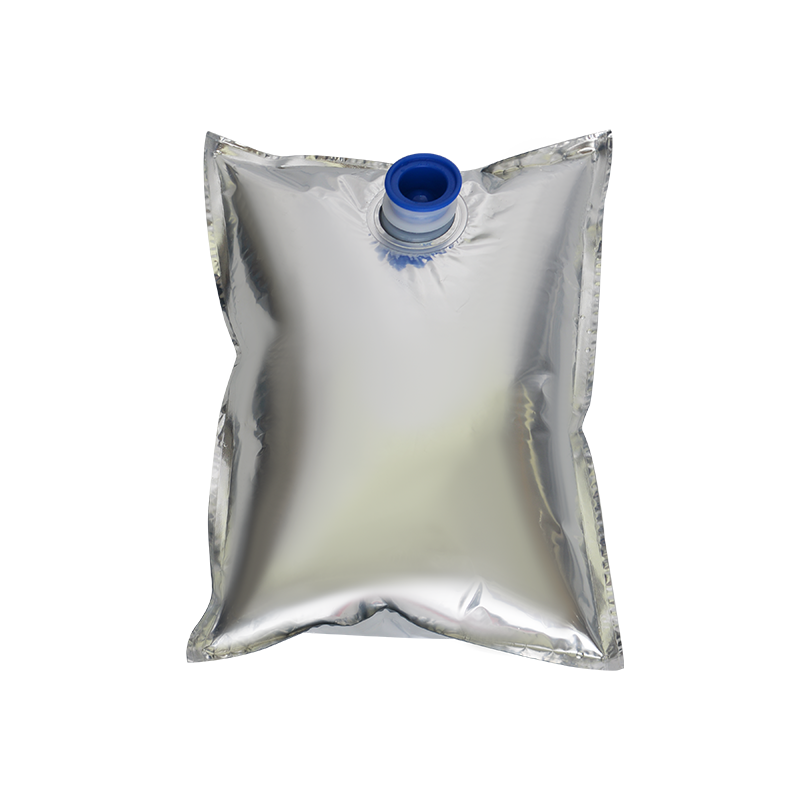

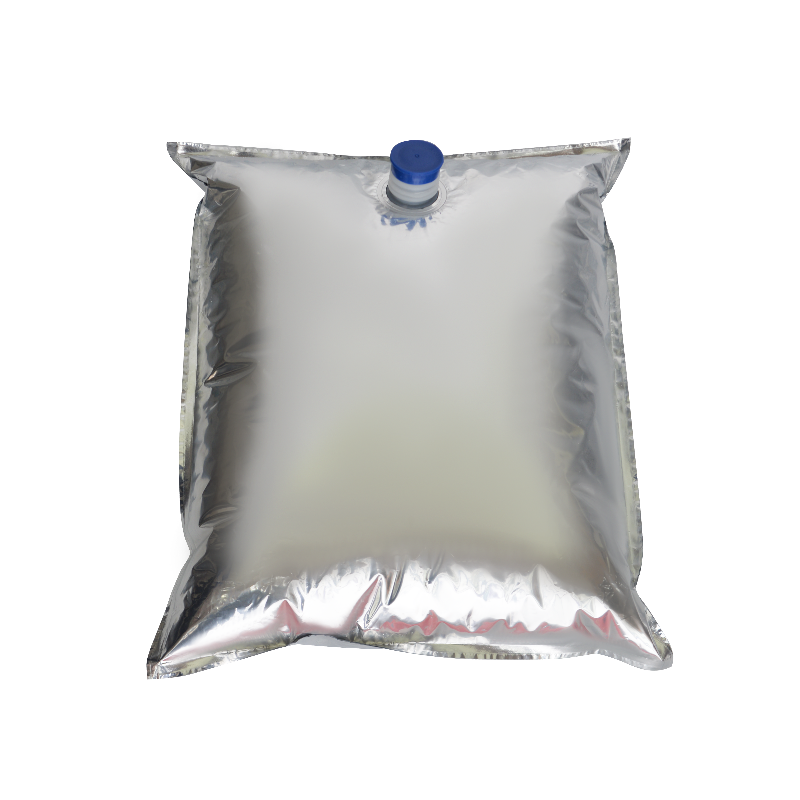

The sterile bag and box system also has excellent environmental adaptability. The PA/PE+PE material used has good oxygen barrier properties, which can effectively prevent food from oxidative deterioration and maintain the freshness and taste of food. At the same time, this material also has good flexibility, allowing bags and boxes to save space and reduce logistics costs during transportation and storage.

The technical features of the aseptic bag and box system are mainly reflected in its unique aseptic processing technology and convenient liquid distribution design. During the production process, the bags and boxes and their contents undergo strict aseptic treatment to ensure that they are free from microbial contamination during the packaging process. To achieve this goal, high temperature short-time sterilization (HTST) or ultra-high temperature instant sterilization (UHT) technology is usually used, combined with advanced aseptic filling equipment, to ensure the sterility of the product throughout the entire production chain.

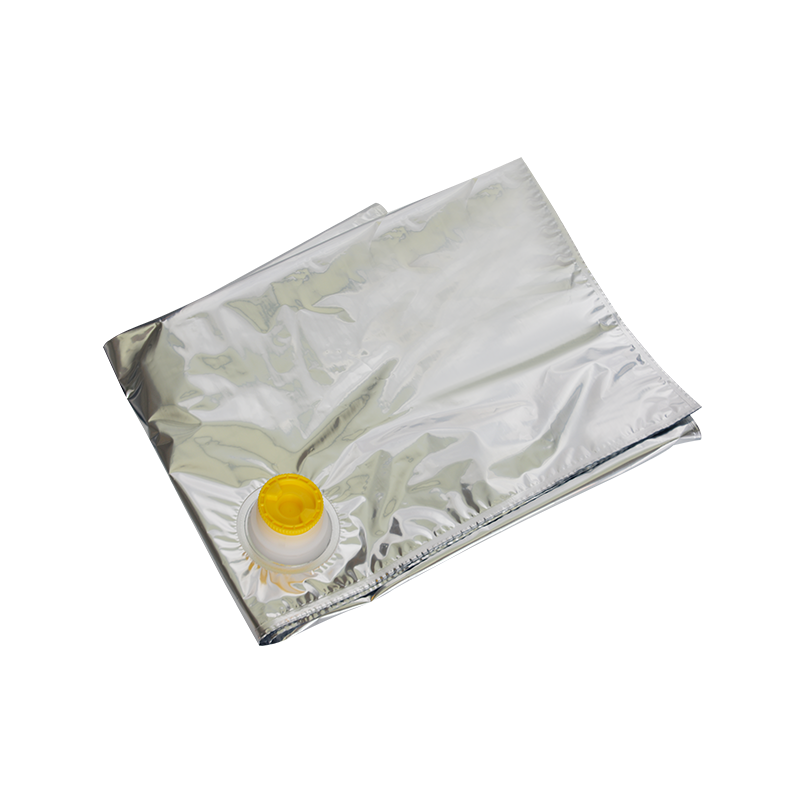

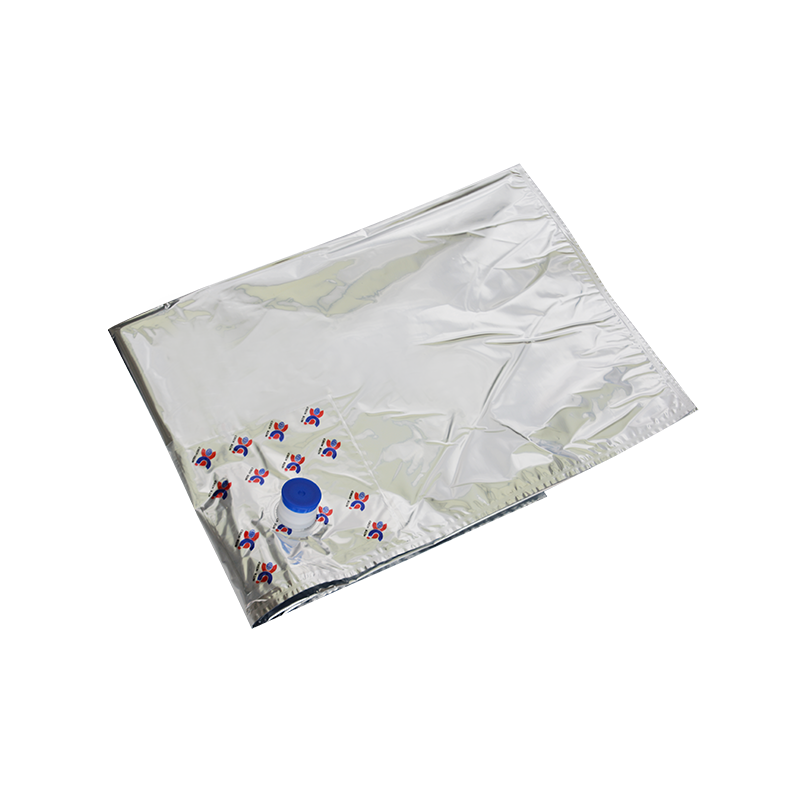

In terms of liquid distribution design, sterile bag and box systems usually adopt a bag design with a sterile nozzle, which is sealed by a sterile cap when not in use to prevent the entry of external microorganisms. When liquid needs to be dispensed, the user only needs to open the sterile cap and the liquid can be easily poured out through the nozzle, which is convenient and hygienic.

Aseptic bag and box systems are used in a wide range of applications, not just in the food industry. In the medical industry, sterile bags and boxes are used to package medical supplies such as infusions and vaccines to ensure their sterility during transportation and use. In the chemical industry, sterile bags and boxes are used to package various chemicals, such as paints, coatings, etc., to prevent them from being contaminated during storage and use.

As consumers' requirements for food safety and quality continue to increase, and food distribution services become increasingly popular, the market prospects for aseptic bag and box systems are very broad. Especially in the rapidly developing takeout and catering industries, aseptic bags and boxes have become the preferred packaging solution for many businesses due to their excellent shelf life and convenience.

In the future, sterile bag and box systems will continue to develop in a more efficient and environmentally friendly direction. On the one hand, with the advancement of material science, more new materials with excellent barrier properties and degradability will be developed to replace the existing PA/PE+PE materials and further reduce the impact of packaging on the environment. On the other hand, with the continuous development of automation and intelligent technology, the production and filling process of sterile bag boxes will be more efficient and precise, thereby reducing production costs and improving product quality.

English

English русский

русский