Sterile bags are widely used in sterile solid raw materials, sterile pharmaceutical excipients, sterile preparations, and other products due to their sterility, non-toxicity, low-temperature resistance, good chemical stability, and electrical insulation properties. Transshipment and temporary storage, as well as transit packaging of sterile rubber stoppers from cleaning to filling lines. In order not to affect the use of the product, strict quality control is required. Here we will introduce to you the factors that affect the quality of sterile bags.

1. The oxygen barrier performance of the bag body. There are three commonly used isolation materials:

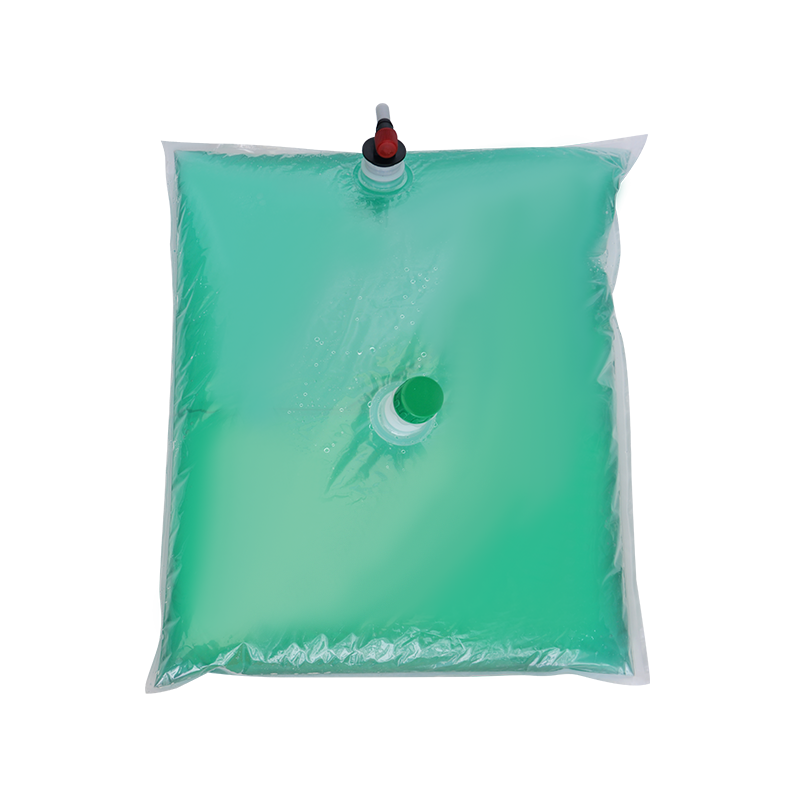

1. For basic isolation, use aluminized PET;

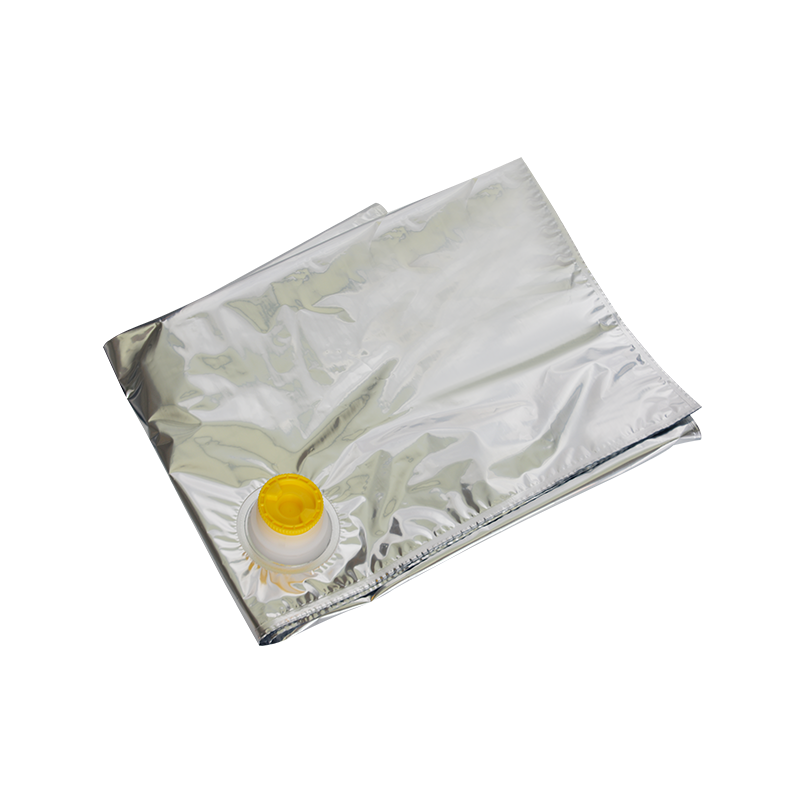

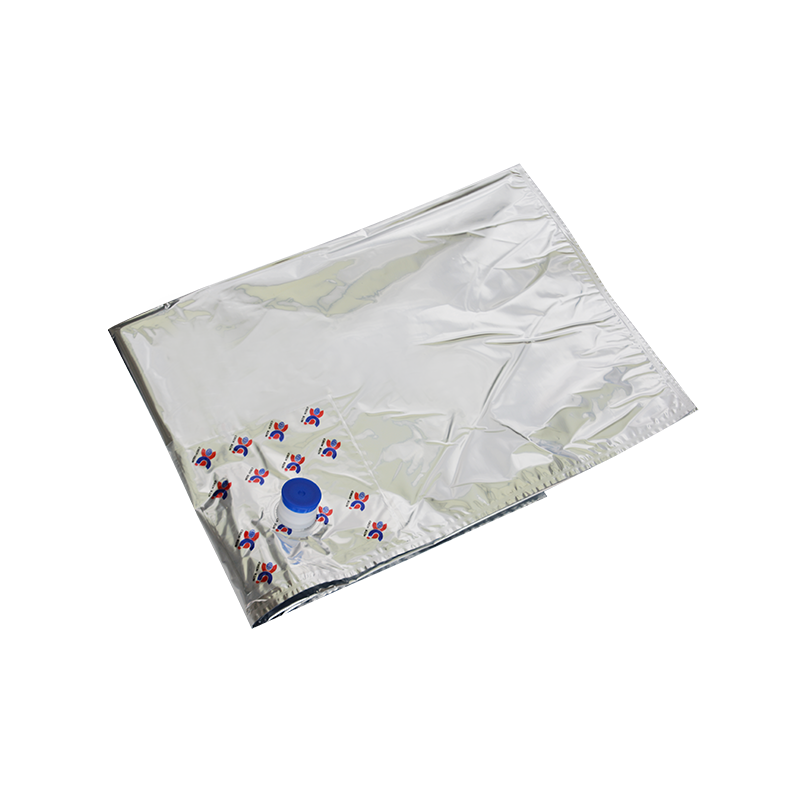

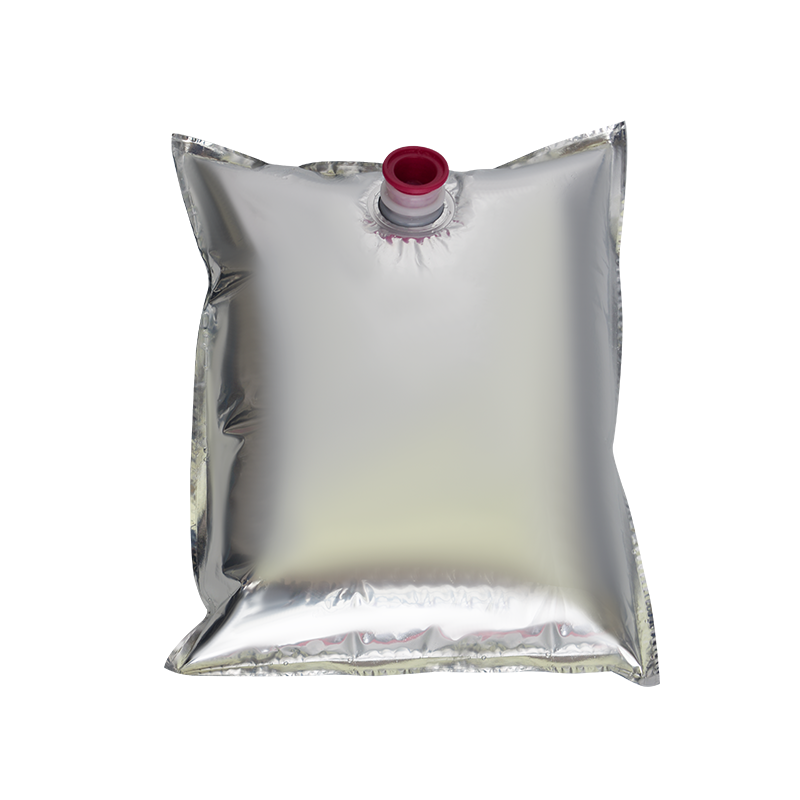

2. High isolation, using aluminized PET+EVOH, for example, we have seen sterile bags with outer membranes compounded with yellow PE films (commonly known as gold bags), or blue PE films to distinguish them;

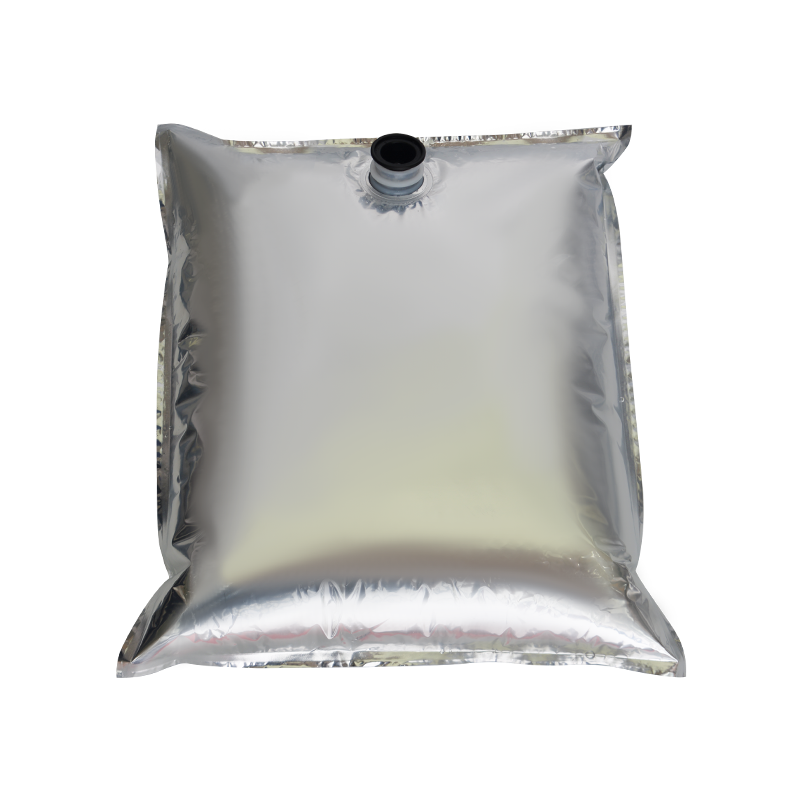

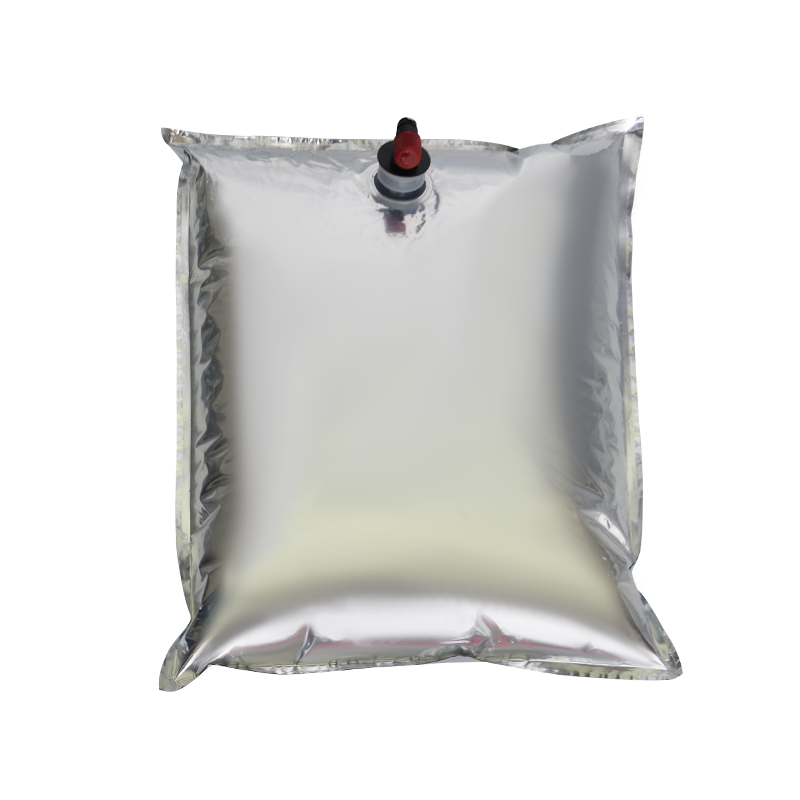

3. Super isolation, using pure aluminum-platinum composite membrane.

The above three different materials correspond to different filling materials respectively and can be used selectively. They are not the same every time. For example, it is recommended to use high-isolation bags for mango pulp and coconut milk. Low-sugar juices such as turbid juices and NFC juices must be stored in ultra-isolated or refrigerated bags.

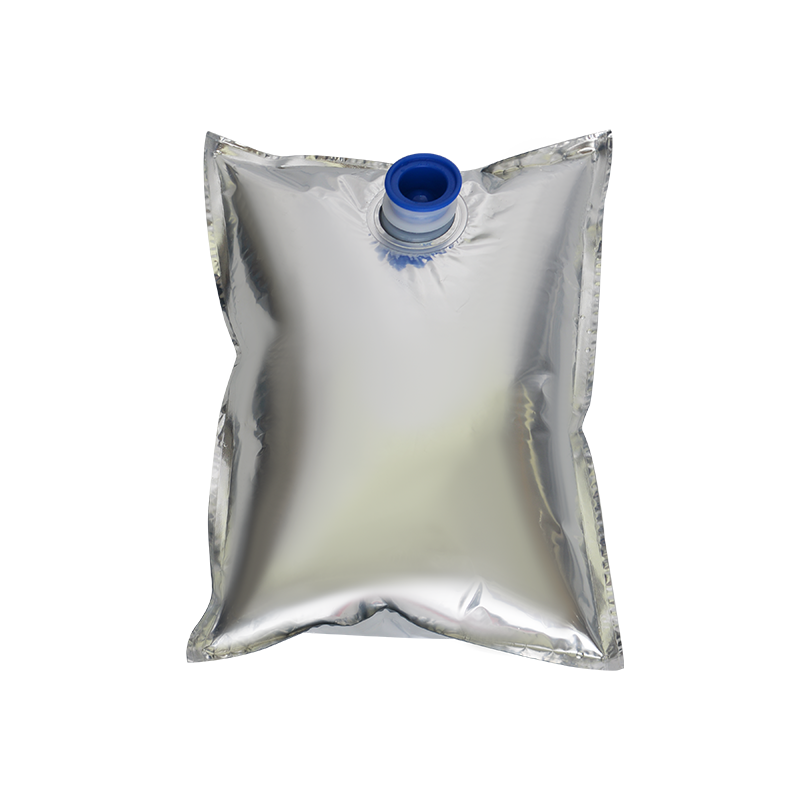

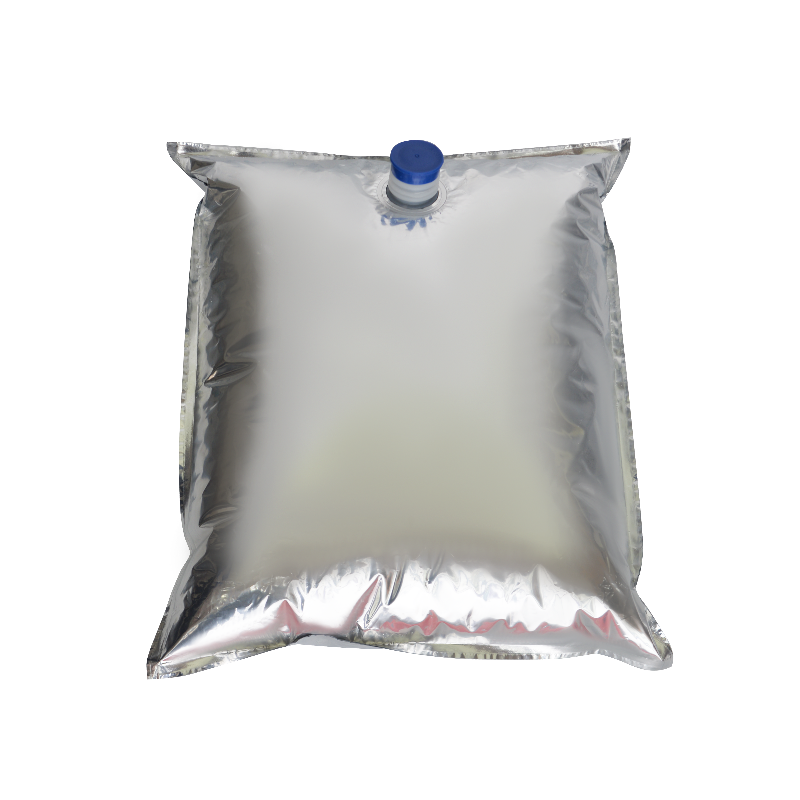

2. Flexibility. The softer the bag, the less likely it is to have crease and point leakage. Several mainstream sterile bag factories are currently undergoing technological transformation to make the bags softer and more wear-resistant.

3. Heat sealability. The heat sealing strength of the bag must be good, pressure-resistant, and impact-resistant. Today’s sterile bag companies can generally meet this technical requirement.

4. Sealing of the lid: The lid of the sterile bag can be said to be the core quality control point. The lid is required to be resistant to high temperatures and freezing temperatures, and be both flexible and strong. The requirements for plastic material formula and plastic mold accuracy are very high. All sterile bag companies that independently produce lids strictly control this quality.

English

English русский

русский