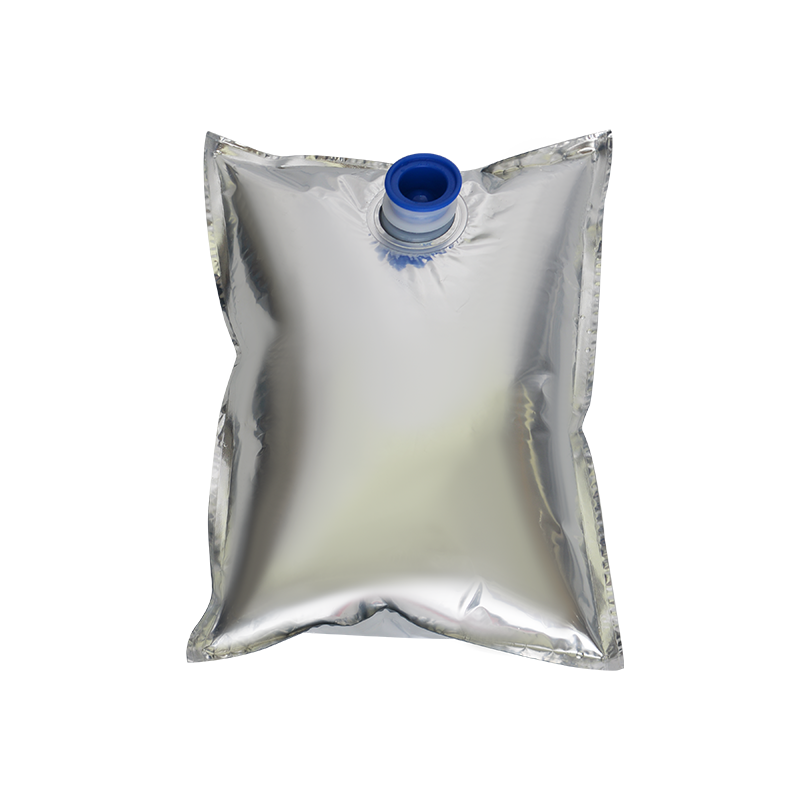

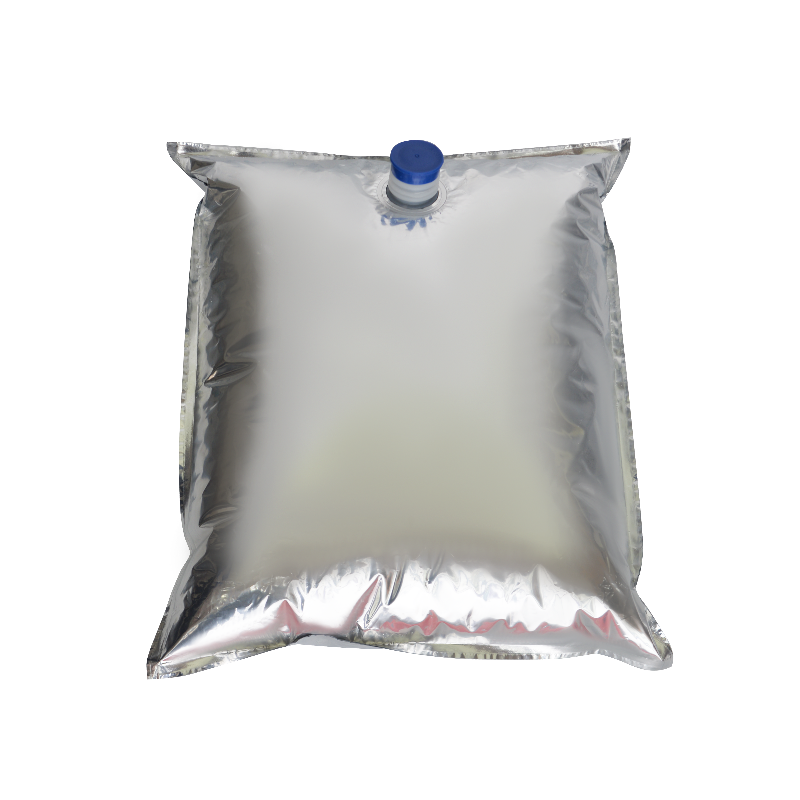

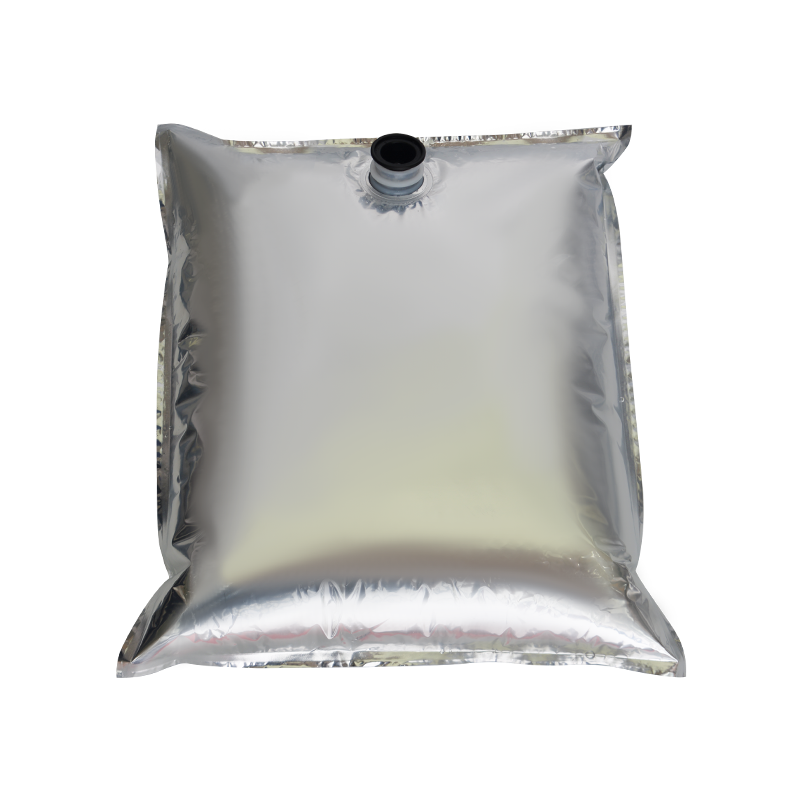

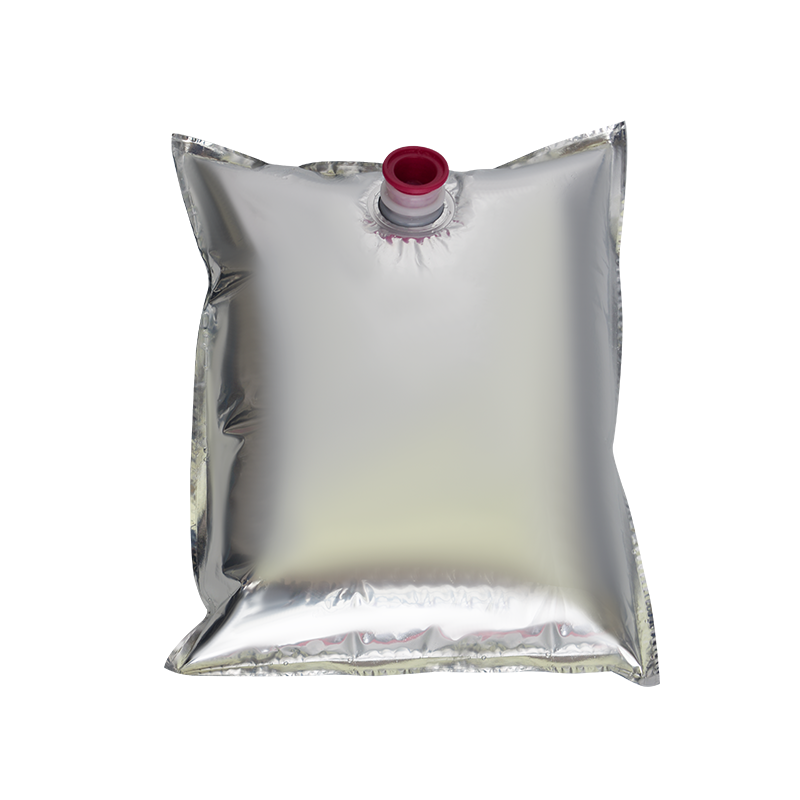

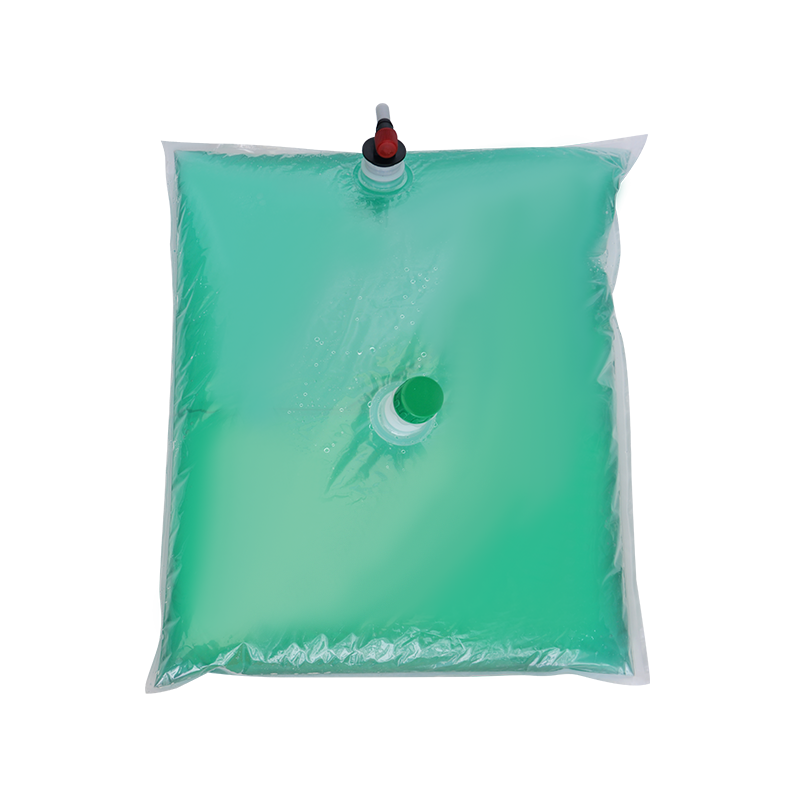

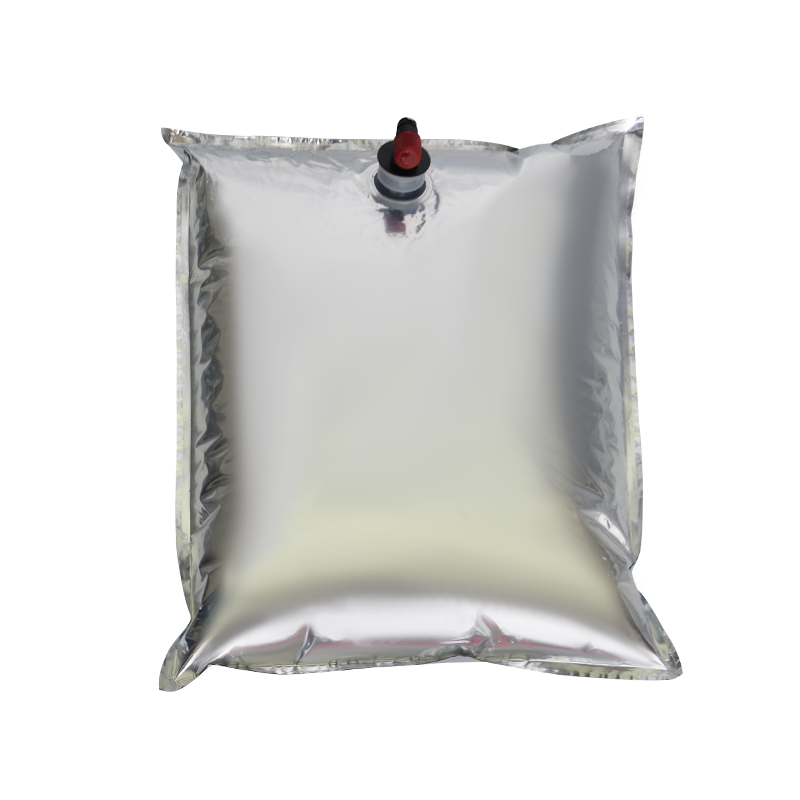

Liquid packaging bags have a relatively large market. From soy milk for breakfast, to juice in the afternoon, to milk before going to bed, they all fall into the category of liquid packaging. Because of this, the demand for liquid packaging is very large, and it is an important order method for flexible packaging companies. Let me share with you some packaging methods for liquid packaging bags:

In the past, liquid packaging bags were mainly stand-up bags and penguin bags. However, with the continuous improvement of customers’ requirements for the appearance and performance of packaging and the development needs of the entire market, in the past two years, more and more large-scale food and beverage Enterprises have flat flat-bottom bag packaging methods, among which the popular is the eight-side sealing flat bottom bag liquid packaging. Because it is both beautiful and practical, it is deeply loved by the majority of consumers.

Square bottom bags for liquid packaging bags are the mainstream in the shopping mall and the favorite of food companies. If flexible packaging companies can improve the production efficiency and scrap rate of square-bottom bags for liquid packaging, it will effectively enhance the company's competitiveness in the industry. The display of the five sides of the square bottom bag and the larger space than the stand-up penguin bag meet the needs of customers. The square standable bottom makes full use of shelf space and is suitable for large shopping malls and supermarkets. Liquid packaging has high requirements for sealing and heat sealing strength during the bag-making process. When selecting composite bags with different structures, different heat sealing temperatures, heat sealing pressures, and heat sealing times need to be set. Once there is an error in operation, the product will become scrap, the scrap rate will increase, and the cost of bag making will also increase accordingly. Therefore, this requires flexible packaging companies to understand the functional characteristics of composite bags, be proficient in operating related bag-making machines, and be able to solve problems in the production process promptly.

English

English русский

русский