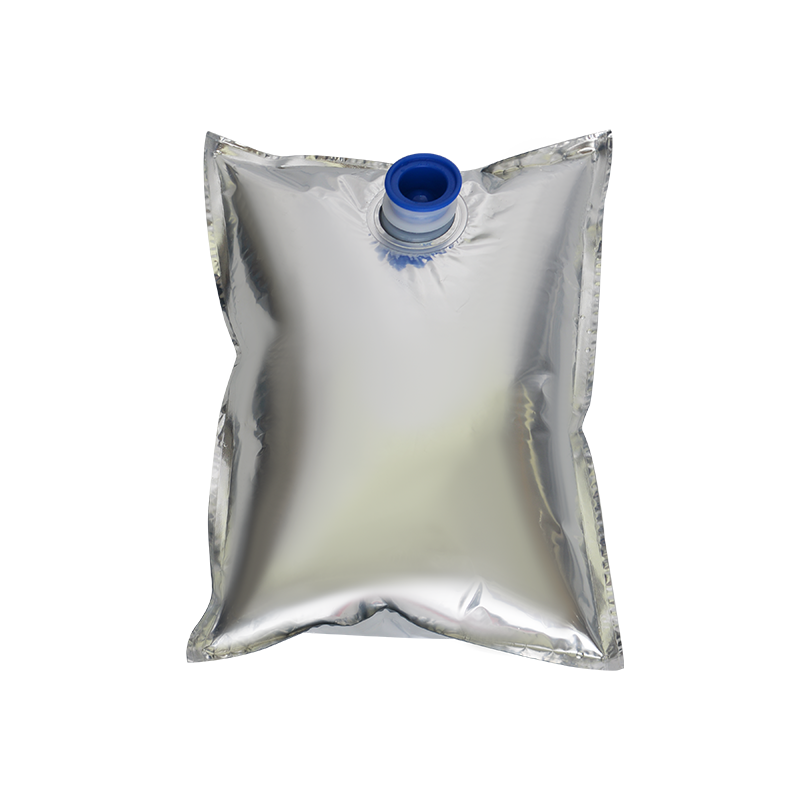

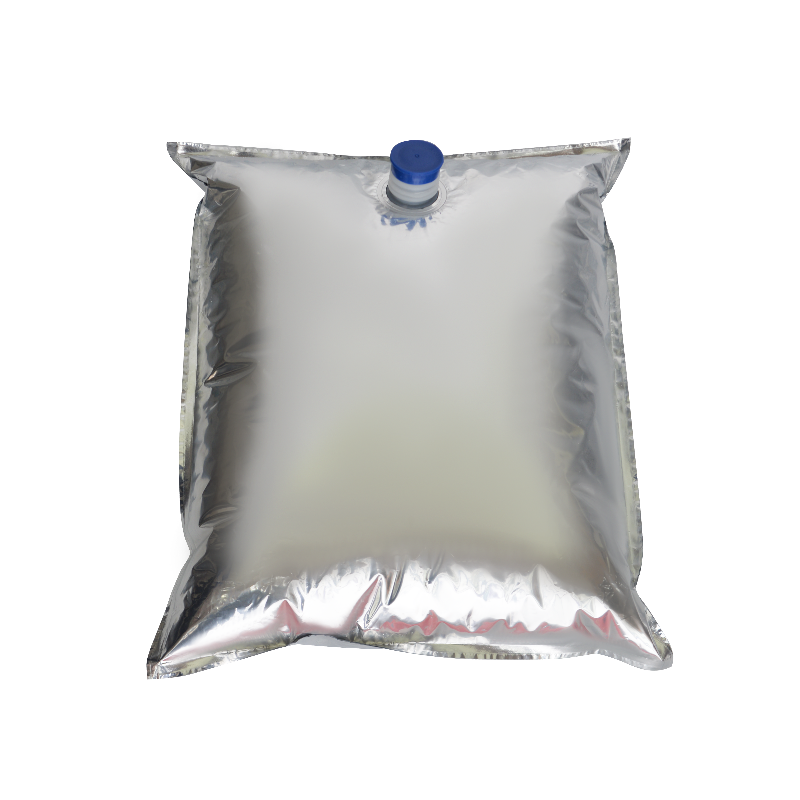

In the food industry, it is crucial to ensure the hygiene and sterility of products during packaging, especially for foods like juice concentrates, diced tomatoes, apple purees, sauces and ketchup. These sterile bags, especially designed for 220 liter capacity, provide an ideal environment for food products to maintain their quality and safety during packaging, storage and transportation.

The manufacturing process of sterile bags strictly follows hygiene and sterility standards. These bags are typically made from multiple layers of materials that offer excellent barrier properties to effectively prevent the penetration of microorganisms, dust, and other contaminants. At the same time, the materials themselves are rigorously screened and tested to ensure that they will not chemically react with food, thereby affecting the quality and safety of the food.

These sterile bags undergo a series of pre-treatment and sterilization steps before packaging. This typically involves thorough cleaning and disinfection of the bag's interior and exterior surfaces using high-pressure steam, UV radiation, or chemical disinfectants. These steps ensure that the bag itself is free of any microorganisms or other contaminants, providing a clean, sterile environment for the subsequent packaging process.

During the packaging process, the use of sterile bags also follows strict operating procedures. First, workers must wear specialized protective clothing and gloves to avoid any possible contamination. At the same time, the entire packaging area will also be kept clean and sterile, with regular disinfection and cleaning.

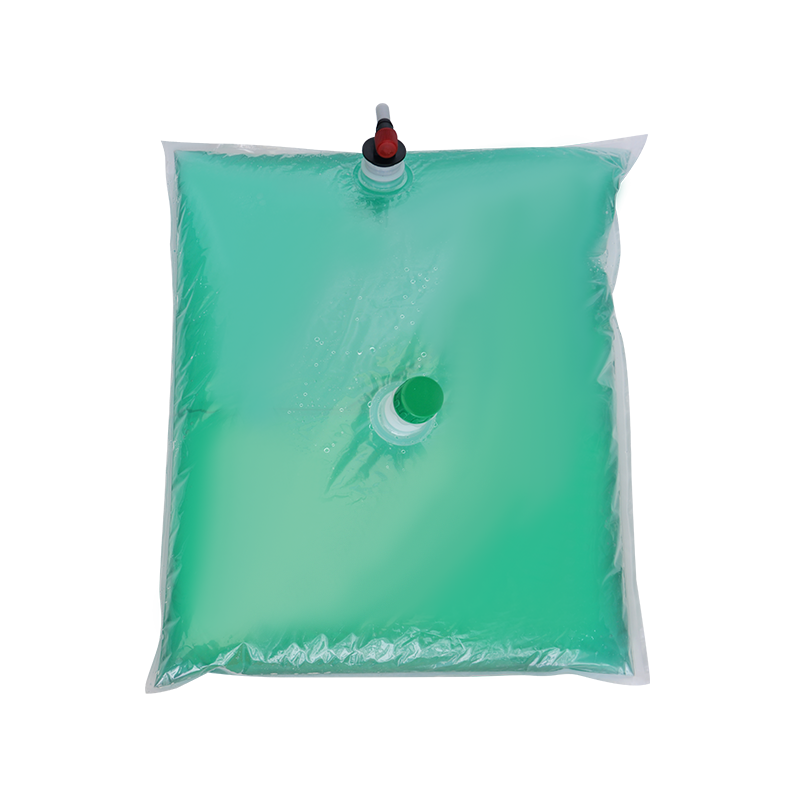

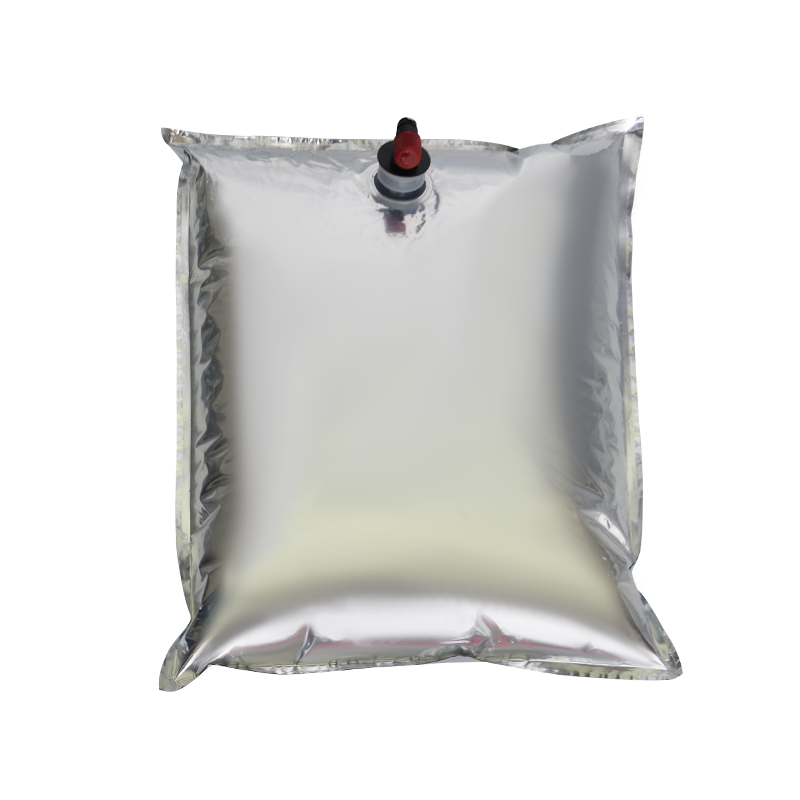

Different packaging technologies and methods may be required for different types of food products, such as juice concentrates, diced tomatoes, apple purees, sauces and ketchup. For example, for foods that require high-temperature processing, the sterile bag may undergo a preheating process to ensure that the internal temperature of the bag reaches the required sterilization temperature when the food is filled. In addition, for some foods that are prone to oxidation, the sterile bags may be equipped with a special gas barrier layer to prevent oxygen from coming into contact with the food, thereby extending its shelf life.

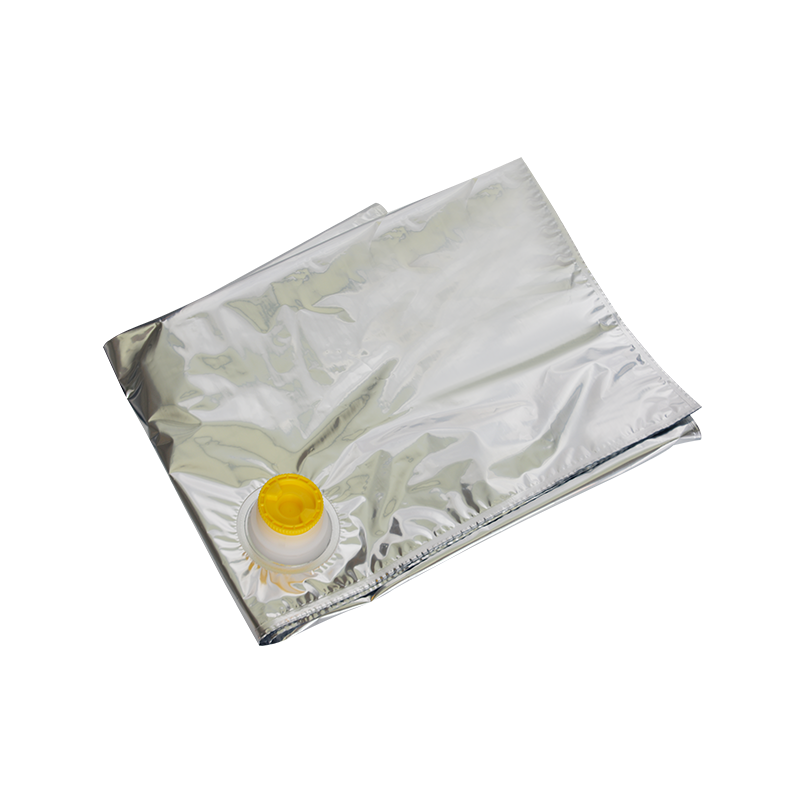

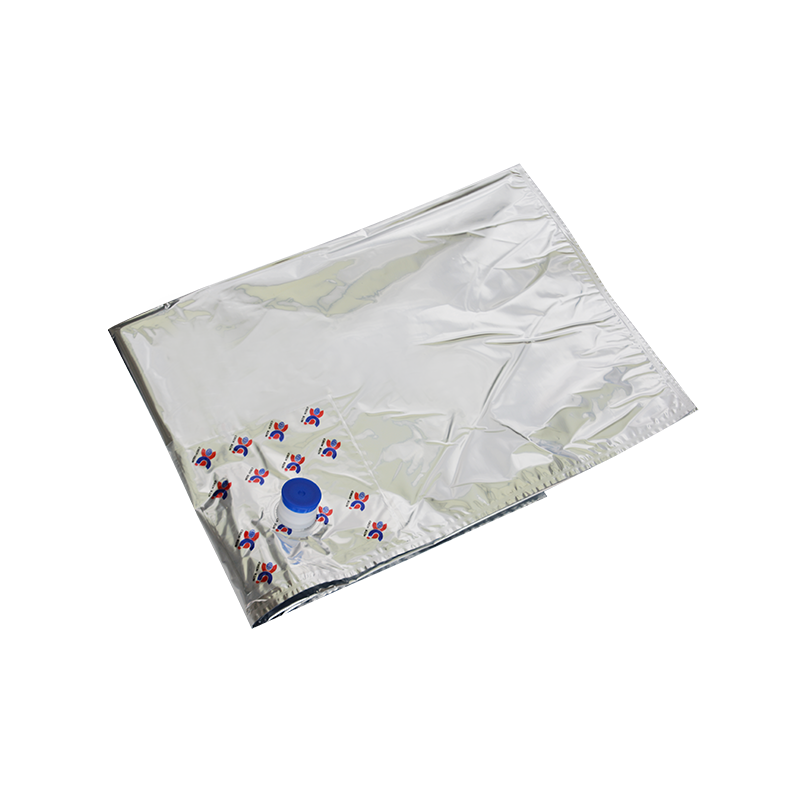

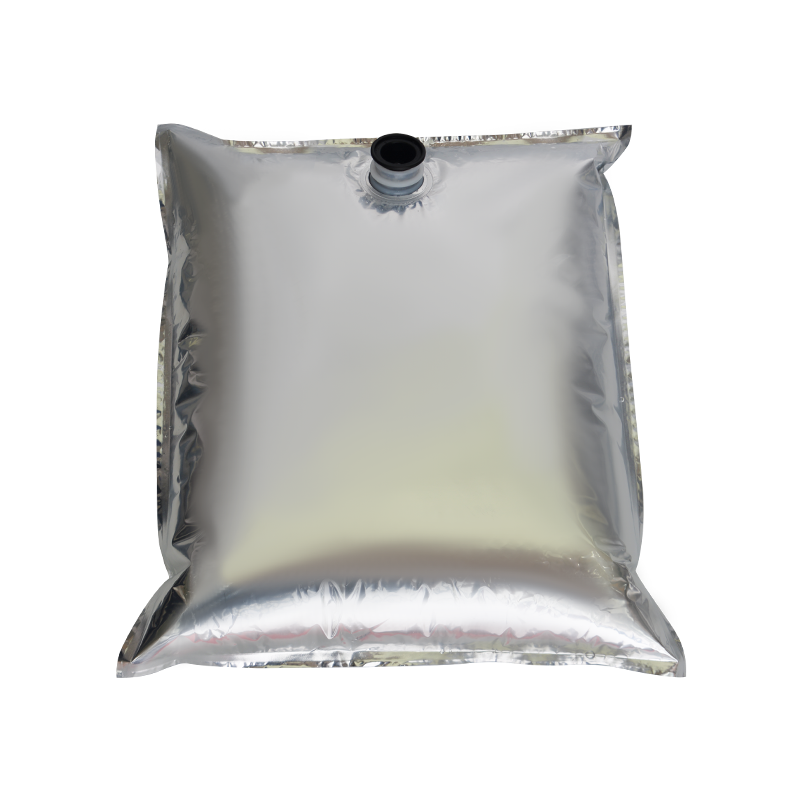

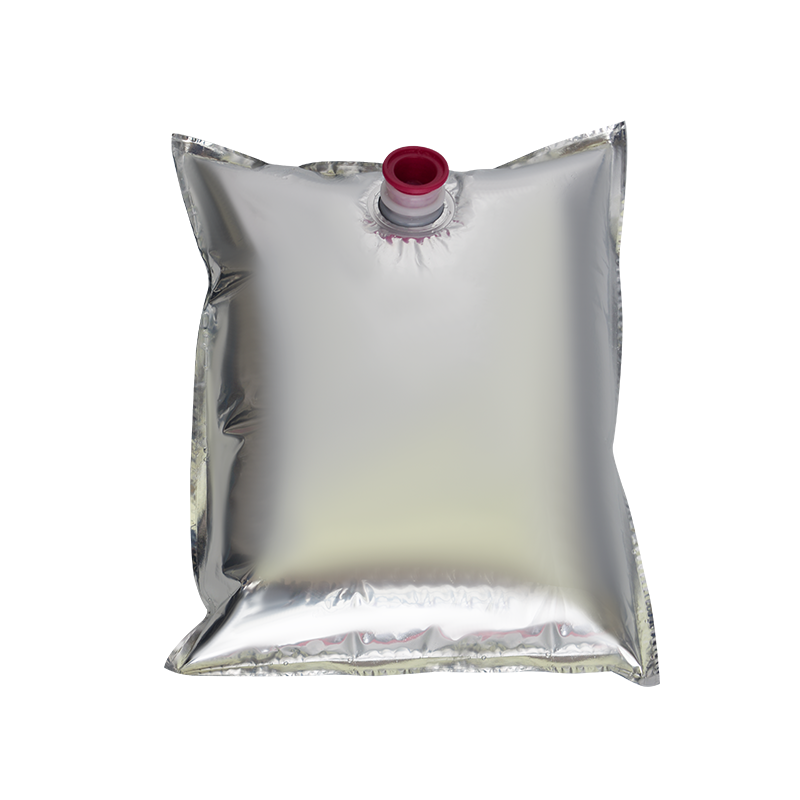

When filling with food, the opening of the sterile bag is connected to the food processing equipment through a special sterile interface. The opening part of the sterile bag is very cleverly designed, and it has the characteristics of speed, accuracy and good sealing. This opening enables efficient filling of food without destroying the overall sterility of the bag. At the same time, this design also avoids the invasion of external microorganisms during the filling process and ensures food safety. The sterile interface is the bridge between the sterile bag and the food processing equipment. This interface is usually made of high-quality stainless steel or other corrosion-resistant materials, with a smooth surface and precise dimensions to ensure a tight fit with the opening of the sterile bag for seamless docking. During the connection process, the sterile interface will undergo strict cleaning and disinfection to ensure that its surface is sterile. When filling food, the food processing equipment will transport the food into the sterile bag through the sterile interface. In this process, the sterile interface plays a crucial role. First, it ensures that food will not be contaminated by external microorganisms during transportation. Secondly, the sterile interface can also control the flow rate and flow rate of food to ensure that food can flow evenly and steadily into the sterile bag during the filling process, avoiding bubbles or gaps.

Once the food is filled into the sterile bag, the bag is immediately sealed and labeled. The sealing process usually uses heat sealing technology to ensure that the bag is completely closed and has no leaks. The markings include production date, shelf life, product name and other relevant information to facilitate traceability and management during subsequent storage, transportation and sales.

These sterile bags also undergo stringent quality checks and testing to ensure that they meet all hygiene and sterility standards. These inspections may include microbiological testing, chemical residue testing, and other physical performance testing. Only sterile bags that pass these inspections can be used to package food and be put on the market for sale.

English

English русский

русский