In today's fast-paced market, the packaging industry is constantly evolving to meet the diverse needs of consumers and businesses alike. Among the myriad of packaging options available, flexible liquid packaging bags have emerged as a revolutionary solution, particularly for liquid products. These bags offer a multitude of benefits that make them indispensable in various industries, from food and beverages to chemicals and pharmaceuticals.

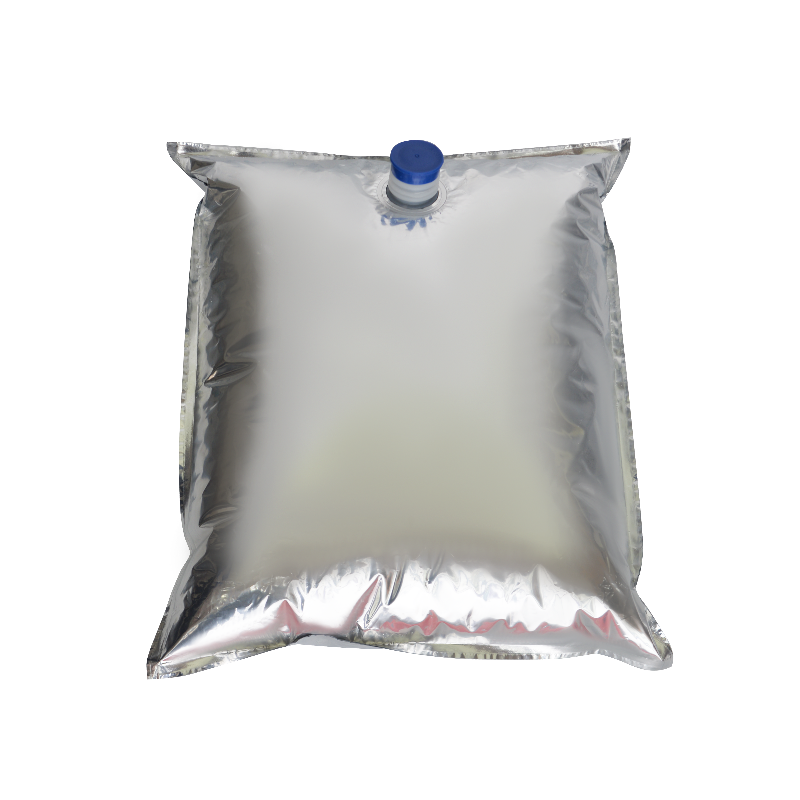

Flexible packaging has seen a surge in popularity due to its versatility, cost-effectiveness, and environmental benefits. Unlike rigid packaging, such as glass bottles or plastic containers, flexible liquid packaging bags can conform to various shapes and sizes, making them ideal for a wide range of applications. Moreover, they are lighter in weight, which reduces transportation costs and carbon emissions.

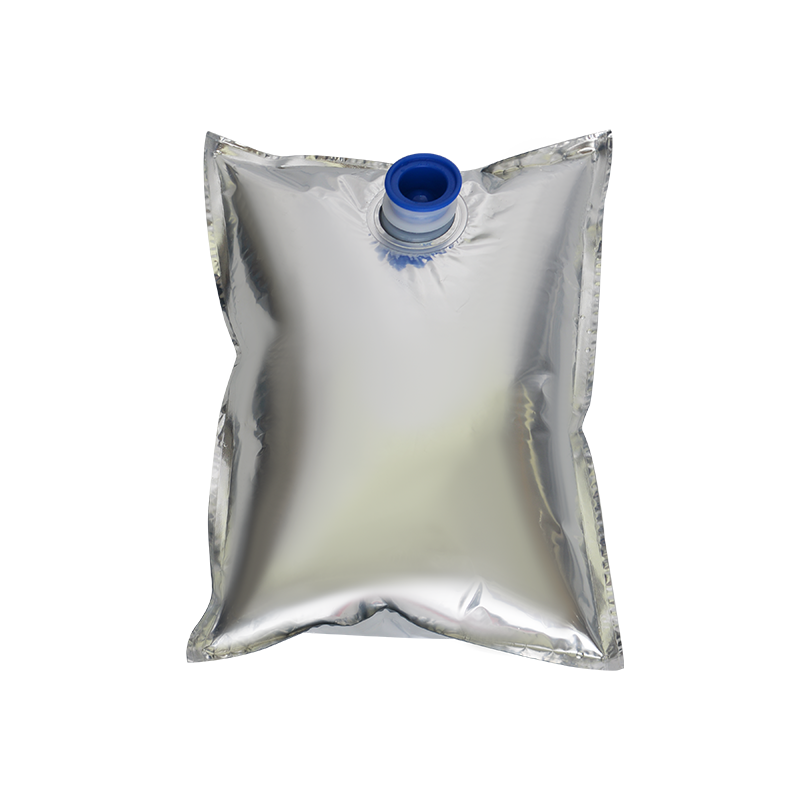

Flexible liquid packaging bags are typically made from multi-layer films that combine different materials to ensure barrier properties against oxygen, moisture, and light. This ensures the integrity and shelf life of the liquid products contained within. The materials used in these bags are often chosen for their durability, strength, and ability to withstand extreme temperatures, making them suitable for both chilled and ambient distribution.

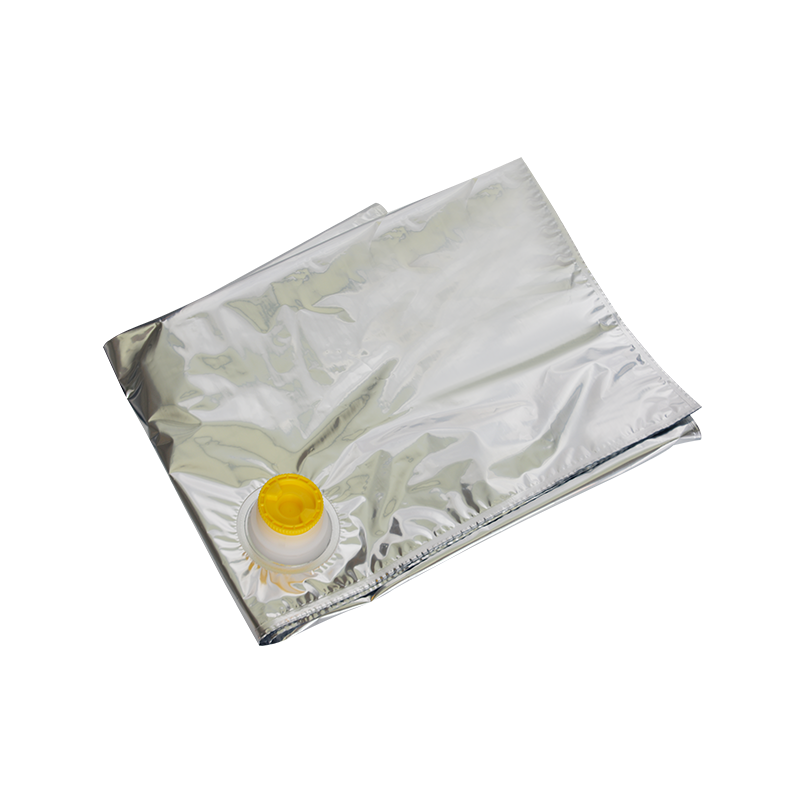

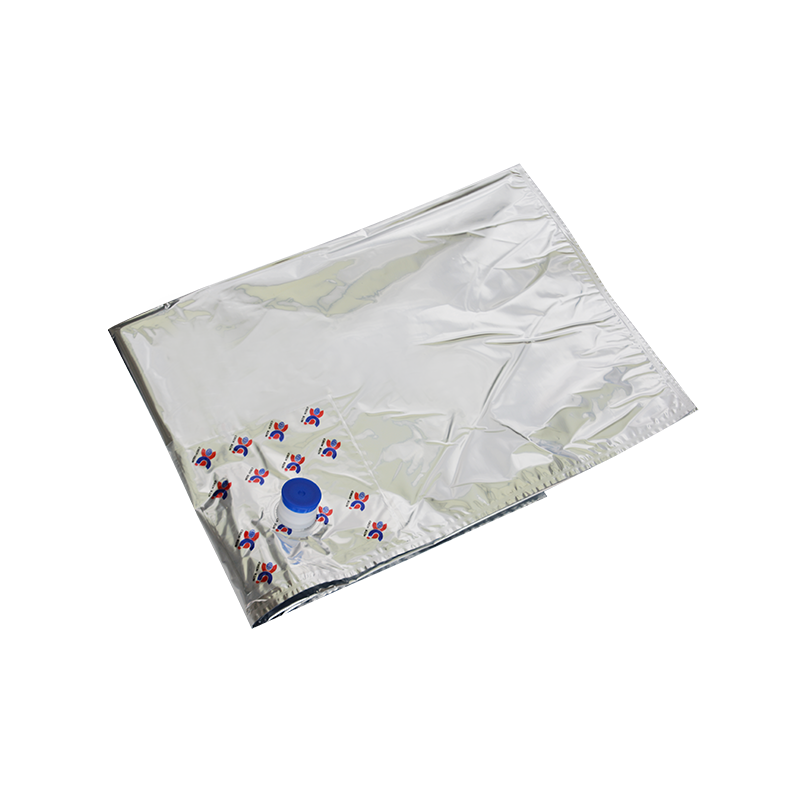

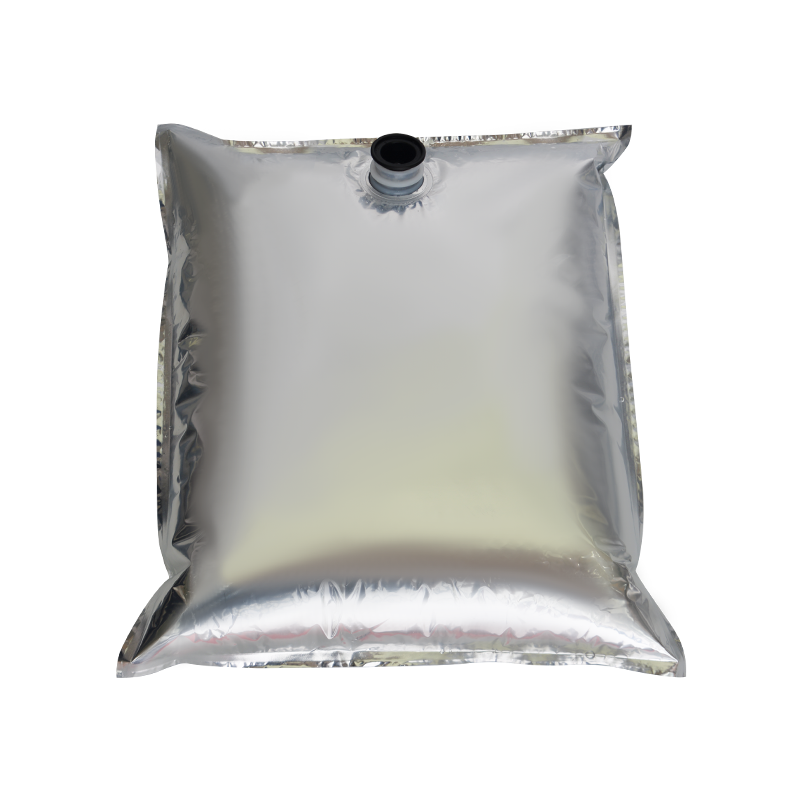

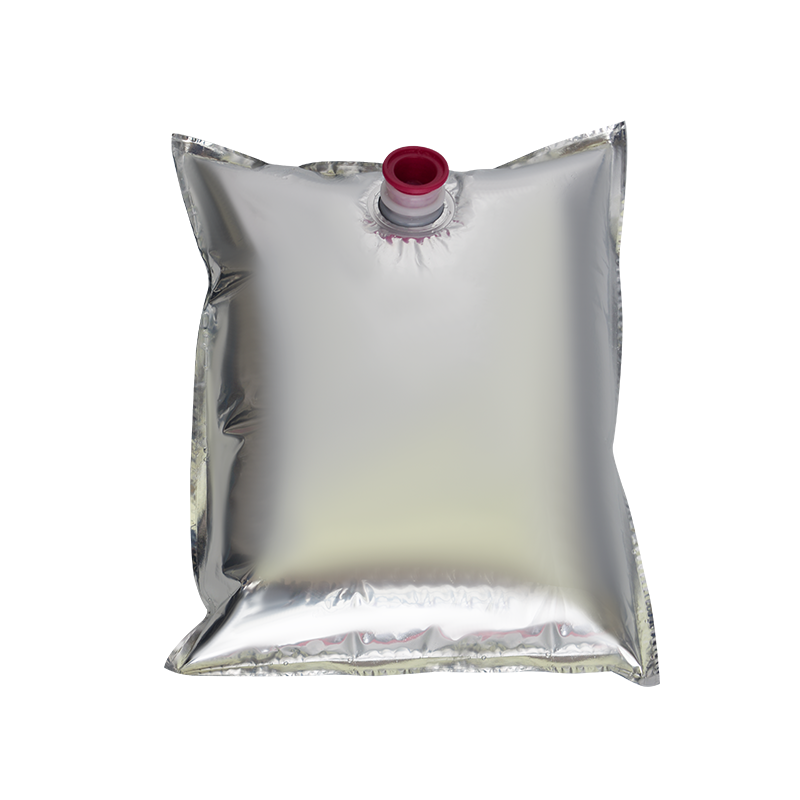

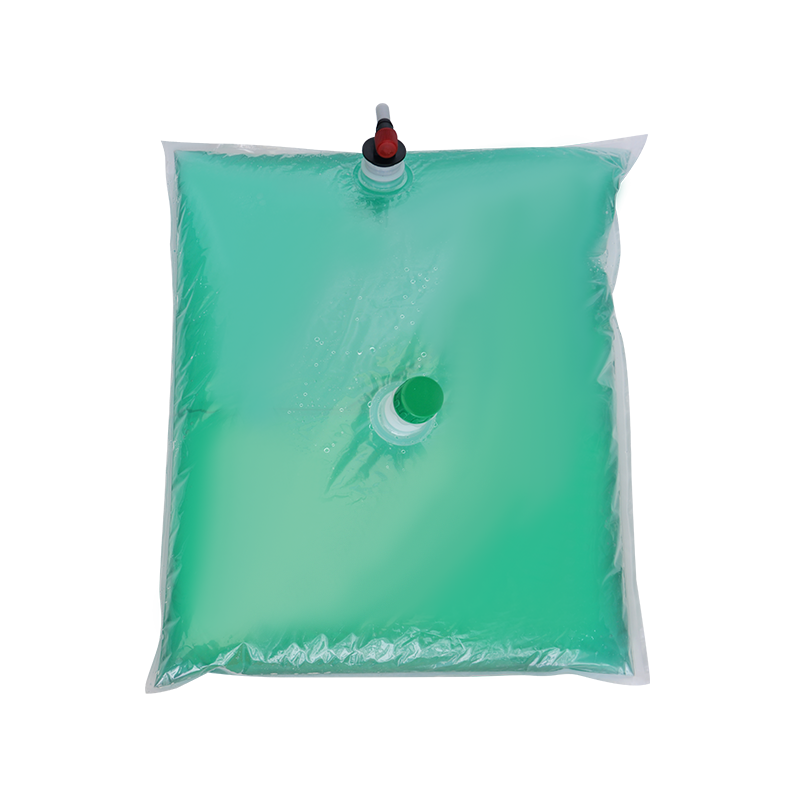

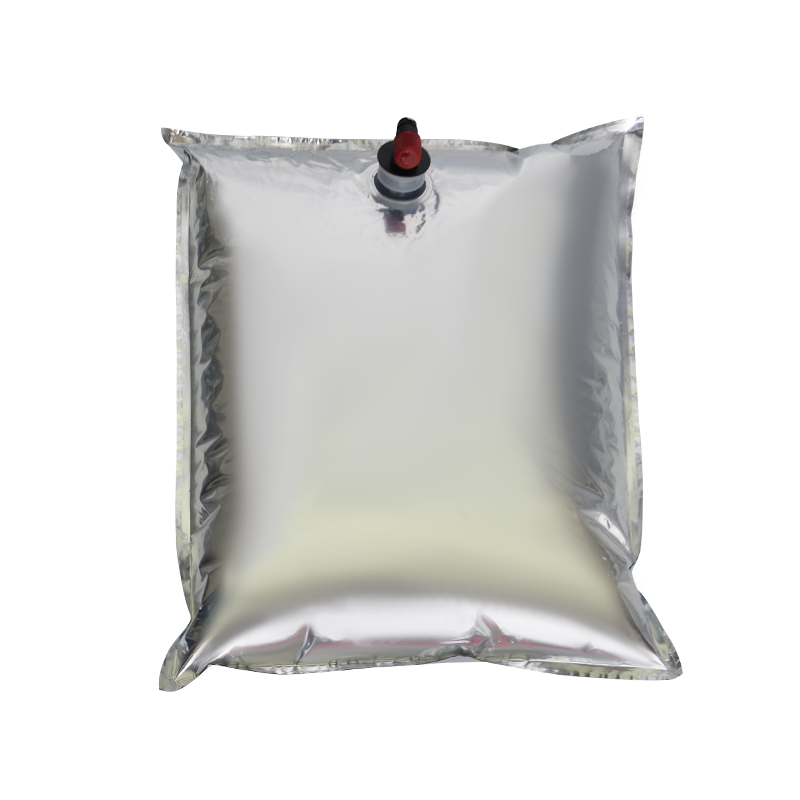

In the food and beverage industry, flexible liquid packaging bags are a staple for products like juices, milk, wine. They offer convenience for consumers, as the bags can be easily squeezed to dispense the liquid, reducing waste and making portion control easier. Additionally, the bags can be equipped with spouts, taps, or resealable caps, enhancing user experience and product versatility.

For manufacturers, flexible packaging offers cost savings through efficient storage and transportation. The bags can be stacked or nested, maximizing warehouse space and minimizing shipping costs. They are less prone to breakage, reducing product loss and waste.

In the chemical and pharmaceutical sectors, flexible liquid packaging bags play a crucial role in the safe and efficient handling of hazardous and sensitive materials. These bags are designed to meet stringent regulatory standards, ensuring the safe containment and transportation of chemicals, vaccines, and other medical liquids.

Their ability to be customized with specific barrier properties makes them ideal for protecting products from contamination and degradation. Moreover, the bags can be equipped with specialized fittings and valves for controlled dispensing, ensuring accuracy and safety during use.

One of the most compelling aspects of flexible liquid packaging bags is their environmental friendliness. Unlike rigid packaging, which often ends up in landfills or oceans, flexible bags can be more easily recycled or incinerated with lower environmental impact. Many manufacturers are now adopting sustainable materials, such as biodegradable and compostable films, to further reduce their carbon footprint.

The lightweight nature of flexible packaging reduces fuel consumption during transportation, contributing to lower greenhouse gas emissions. This aligns with the growing consumer demand for eco-friendly packaging solutions and corporate sustainability goals.

English

English русский

русский