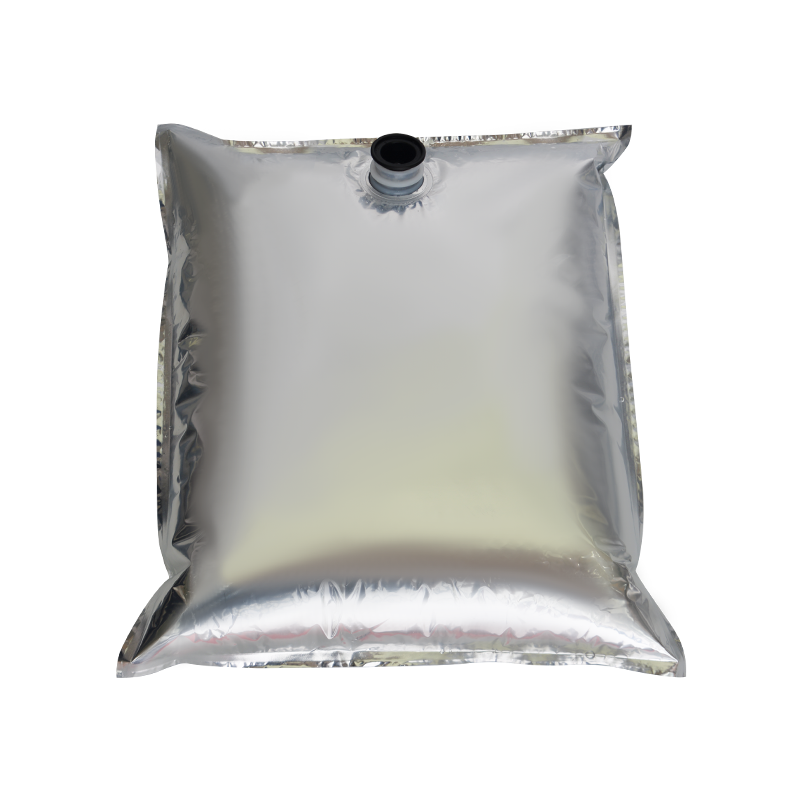

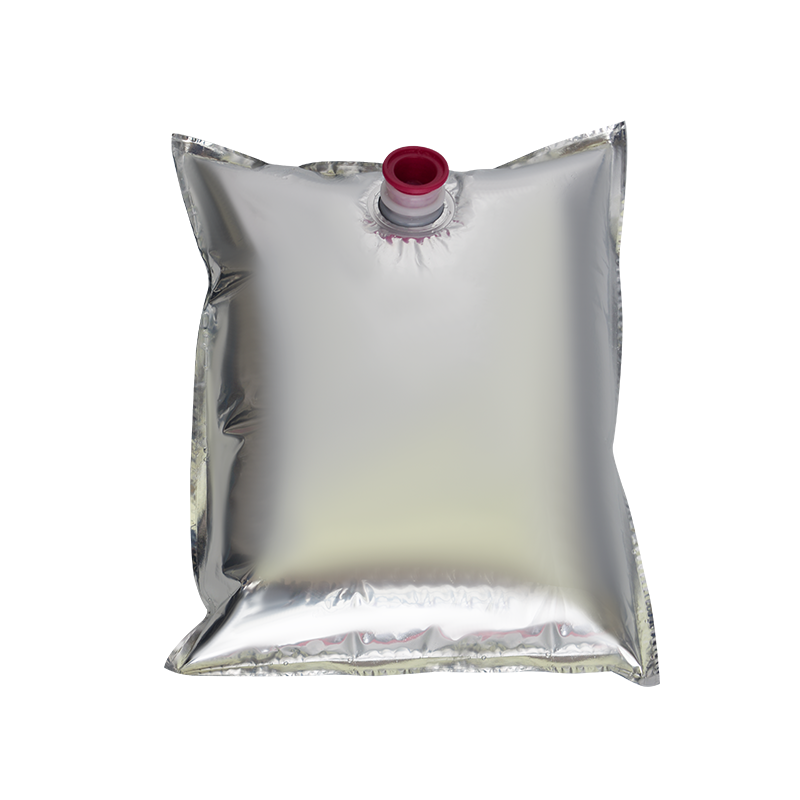

In today's era of high attention to food safety, medical health and life science research, aseptic bags, as a key packaging solution, have not only promoted the progress of the industry, but also profoundly affected our daily life and scientific exploration.

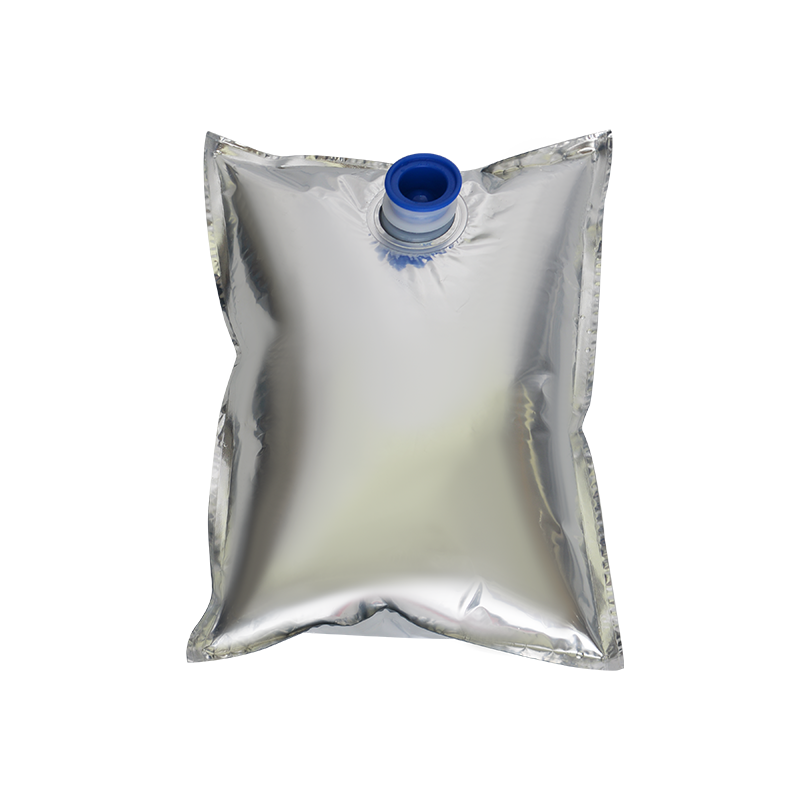

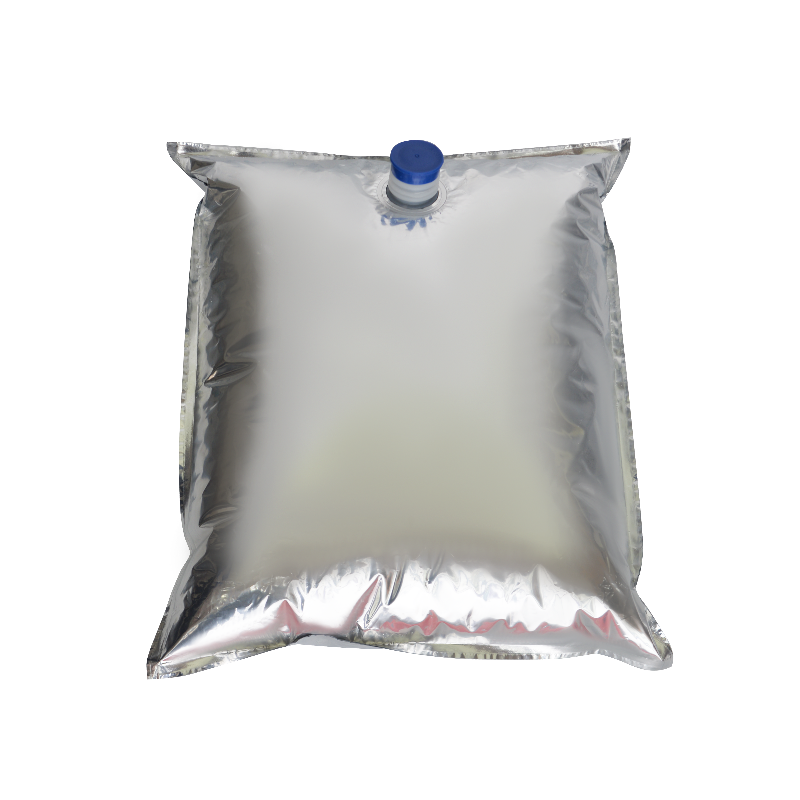

The core of aseptic bags lies in the selection and design of their materials. It requires that the materials can not only effectively isolate the invasion of external microorganisms, but also maintain the sterility of the internal environment, and at the same time have good physical strength, chemical stability and processability. In recent years, with the rapid development of materials science, a series of new materials have been applied to the production of aseptic bags.

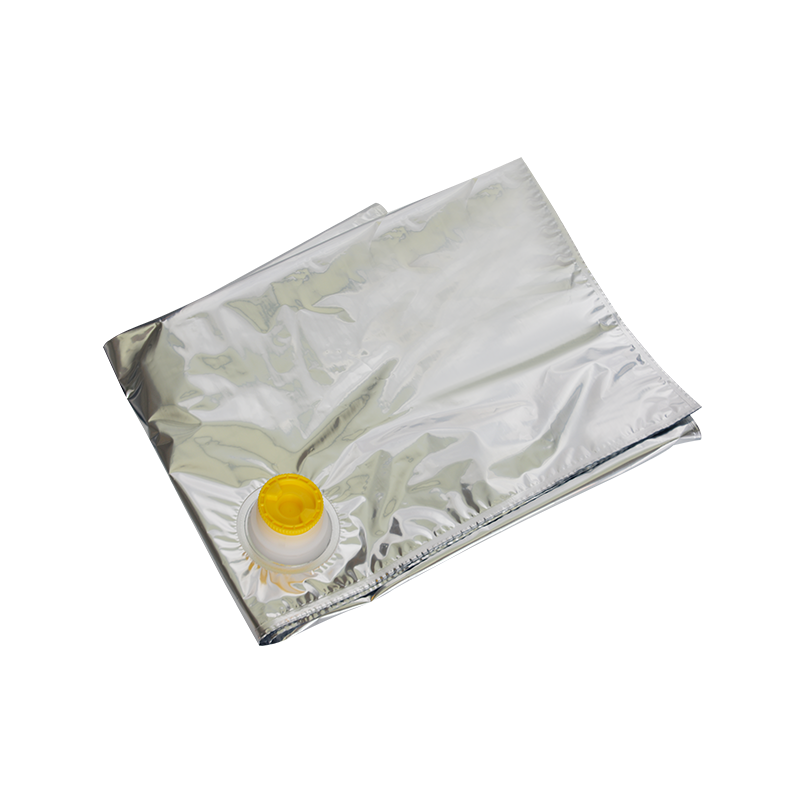

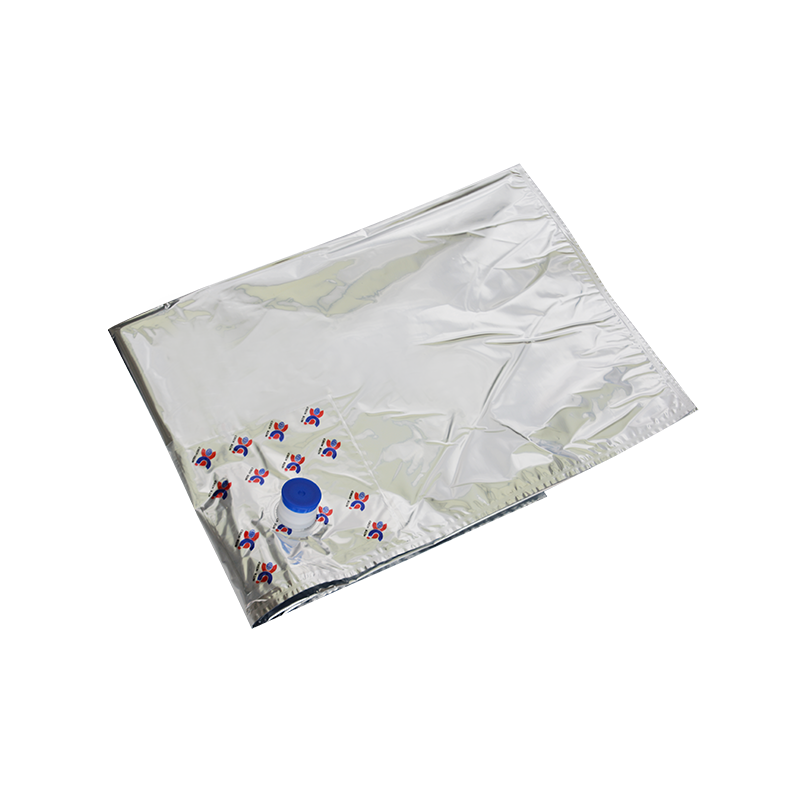

Multi-layer co-extrusion composite film, which is one of the most commonly used materials for aseptic bags at present, is made by co-extrusion and composite of multiple layers of plastic films with different properties. Each layer of material has its own function. For example, the inner layer uses high barrier materials to prevent gas and liquid penetration, and the outer layer emphasizes wear resistance and tear resistance. This structure not only improves the overall performance of aseptic bags, but also reduces production costs.

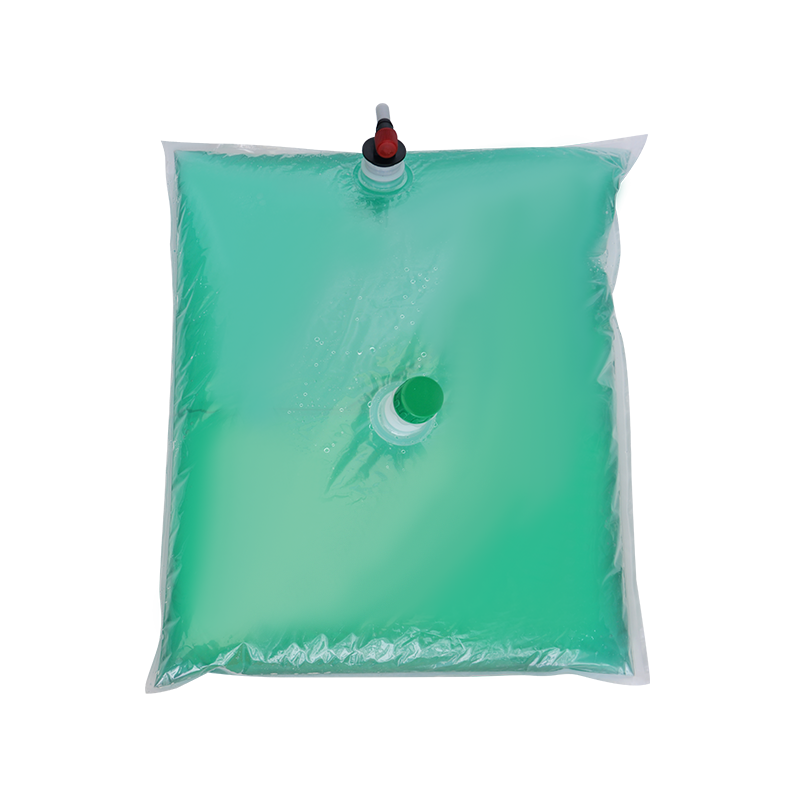

With the enhancement of environmental awareness, bio-based and degradable materials have gradually become research hotspots in the field of aseptic bags. These materials are derived from renewable resources, such as corn starch, cellulose, etc., while maintaining good barrier and aseptic properties, reducing dependence on petroleum resources, and can be naturally degraded after use, reducing the environmental burden.

The introduction of nanotechnology has brought revolutionary changes to aseptic bag materials. The addition of nanoparticles (such as silica, silver nanoparticles) can significantly improve the antibacterial properties, barrier properties and mechanical strength of the material, making it possible for aseptic bags to be used in high-end medical, precision instrument packaging and other fields.

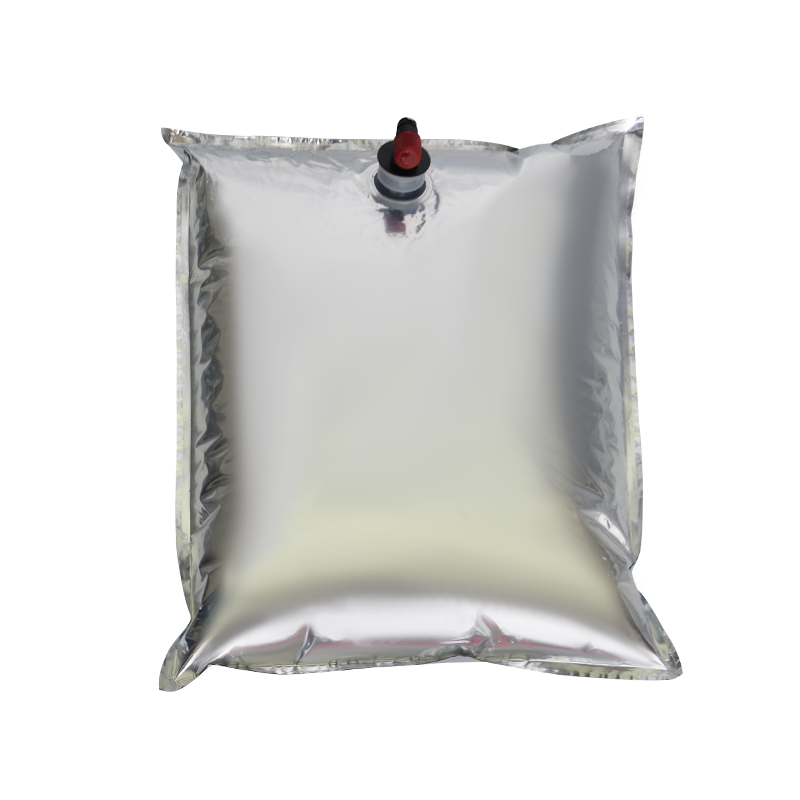

The manufacturing process of aseptic bags has also undergone a transformation from simple to complex, from inefficient to efficient. A series of advanced production technologies have been widely used to ensure the high quality and aseptic state of the products.

The production of aseptic bags must be carried out in a strictly controlled environment to avoid microbial contamination during the production process. Modern aseptic bag production lines are usually equipped with high-level clean rooms, which ensure that the aseptic level of the production environment meets or exceeds industry standards through air purification systems, temperature and humidity control systems, etc.

With the continuous advancement of science and technology and the increasing diversification of consumer needs, the material science and manufacturing process of aseptic bags will continue to develop to a higher level. In the future, we are expected to see more high-performance, environmentally friendly, and intelligent aseptic bag products coming out, which will play a more important role in food safety, medical and health care, biomedicine, aerospace, etc. At the same time, the concept of sustainable development is deeply rooted in people's hearts, and the widespread application of bio-based and degradable materials will also become an important trend in the aseptic bag industry, driving the entire industry to develop in a greener and healthier direction.

English

English русский

русский