In the medical, biotechnology and many industrial fields, aseptic packaging of liquids is a crucial technology. This is not only related to the safety and effectiveness of the product, but also the key to ensuring the health and satisfaction of the end user. In this context, aseptic bag in box, as an innovative packaging form, has become a leader in the field of liquid packaging with its unique design concept and performance.

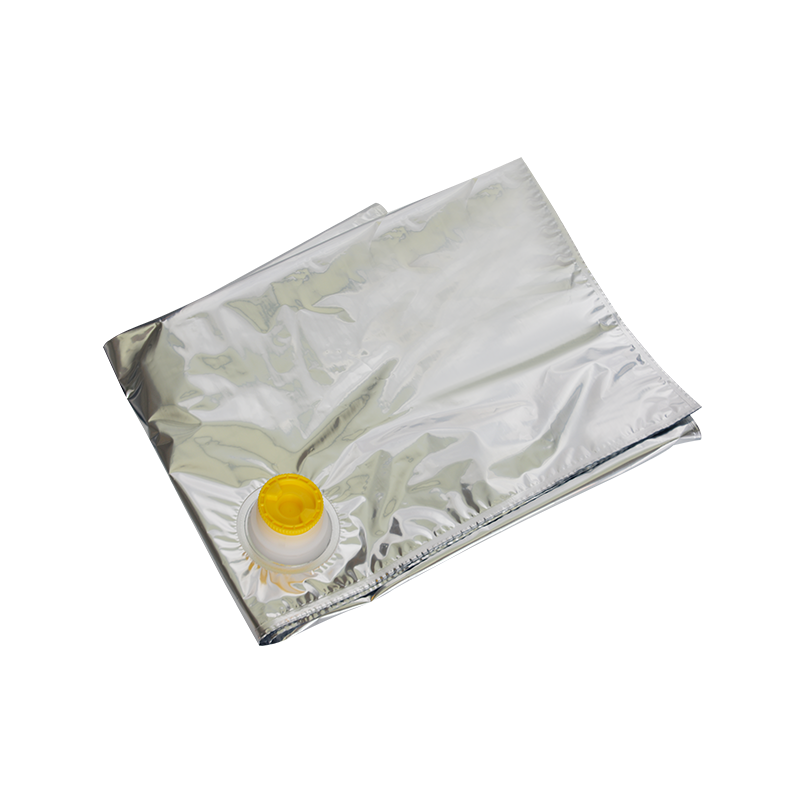

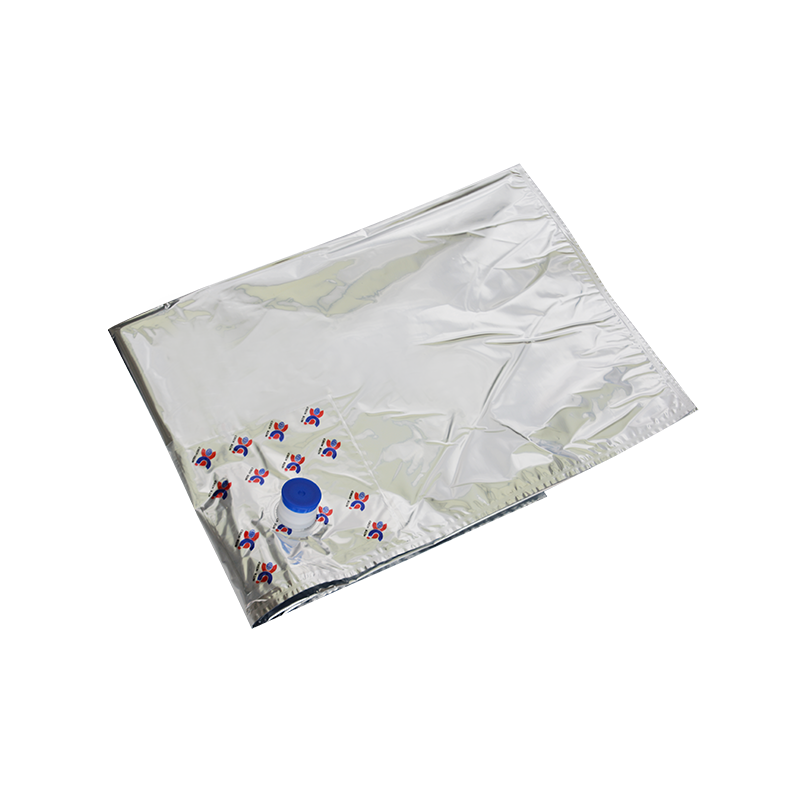

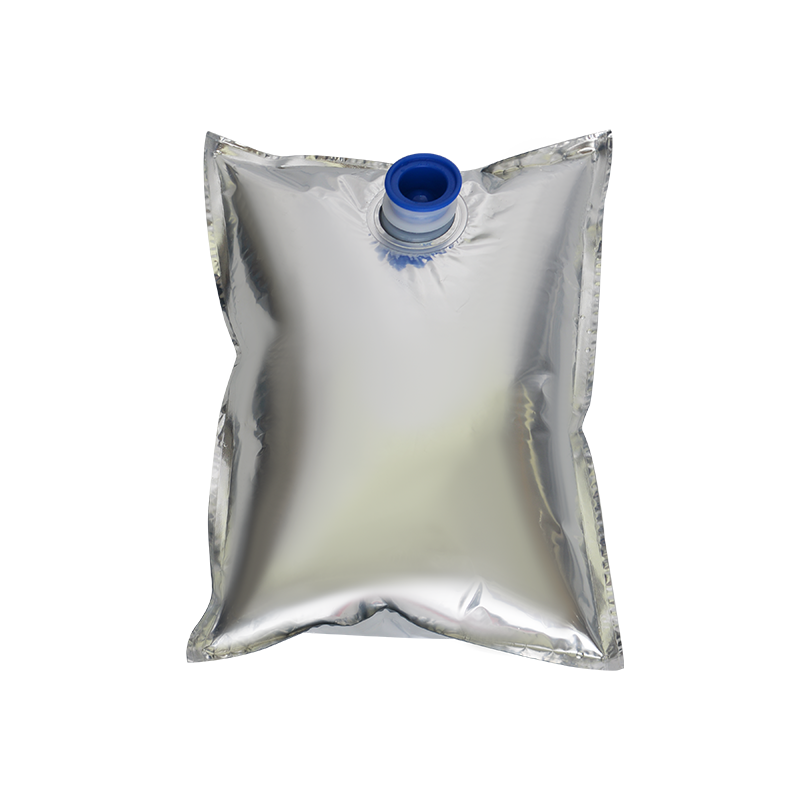

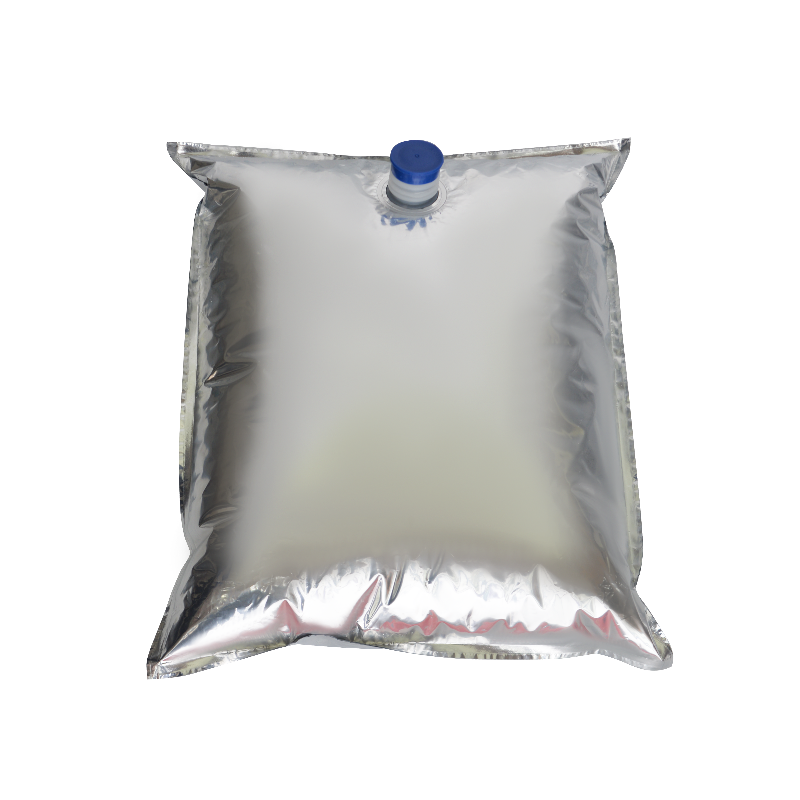

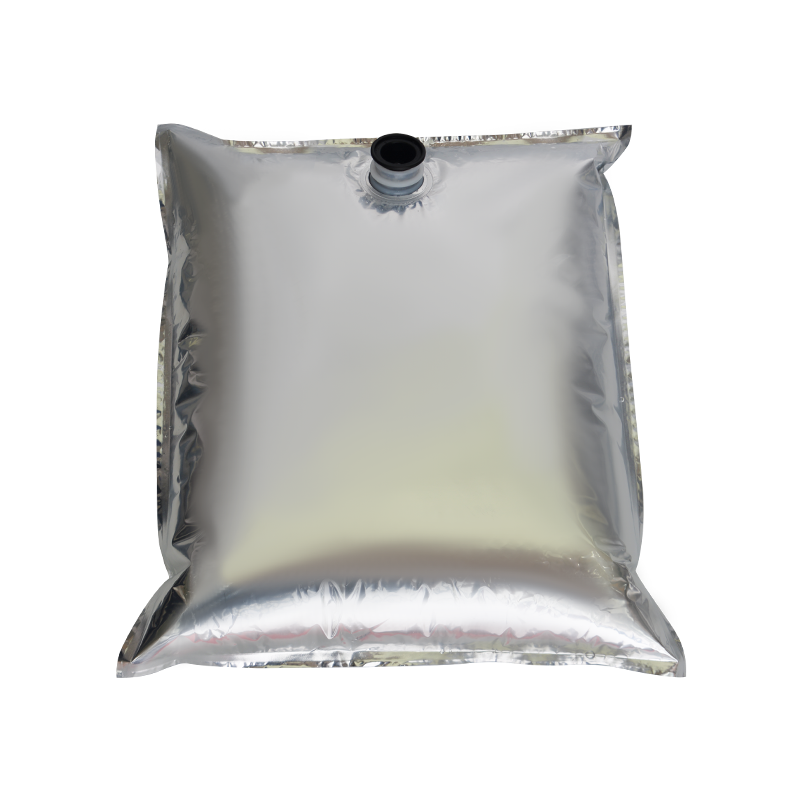

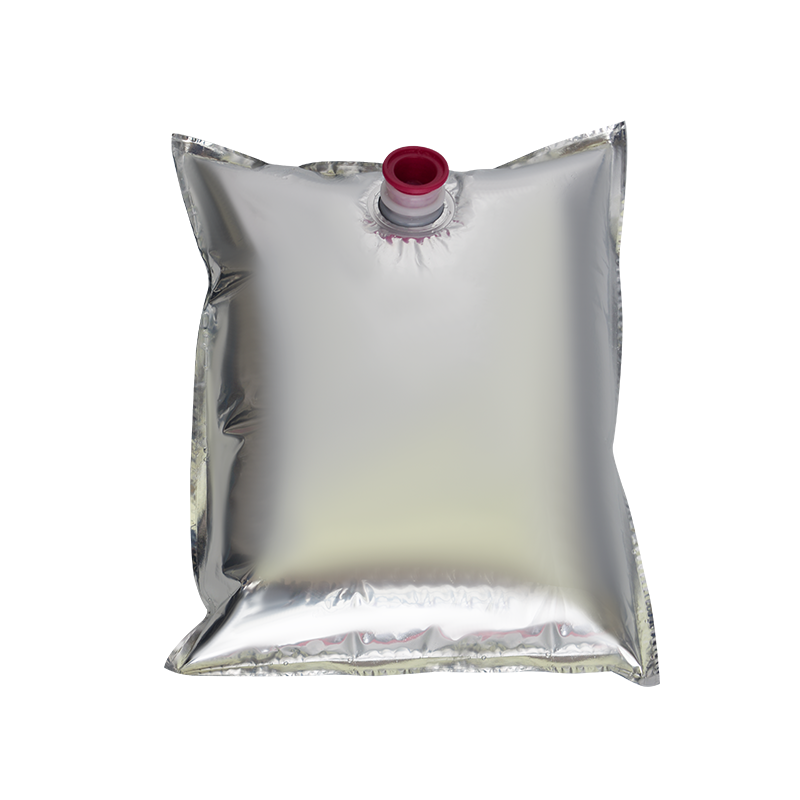

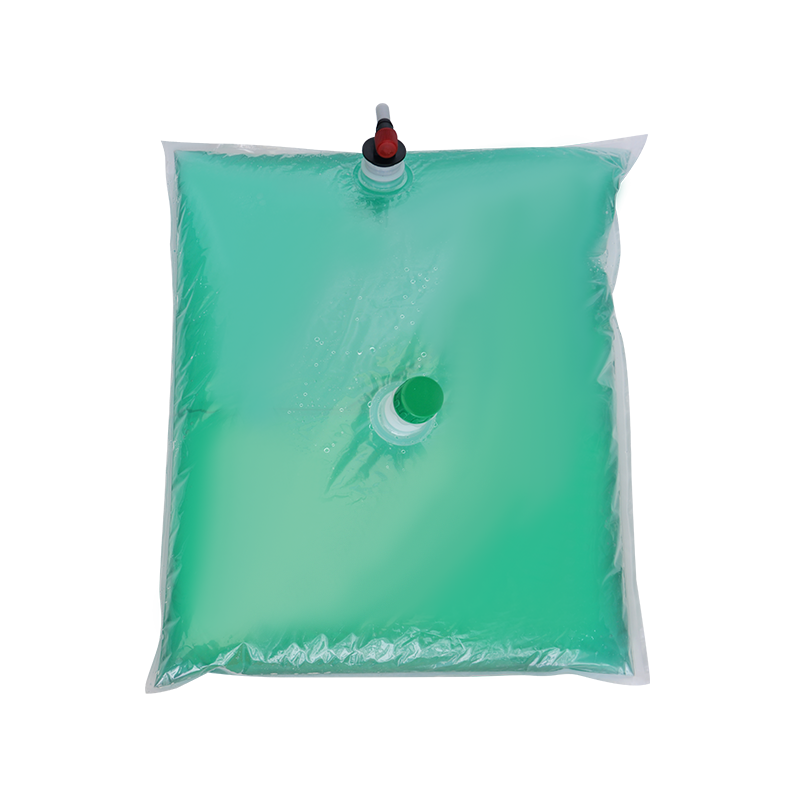

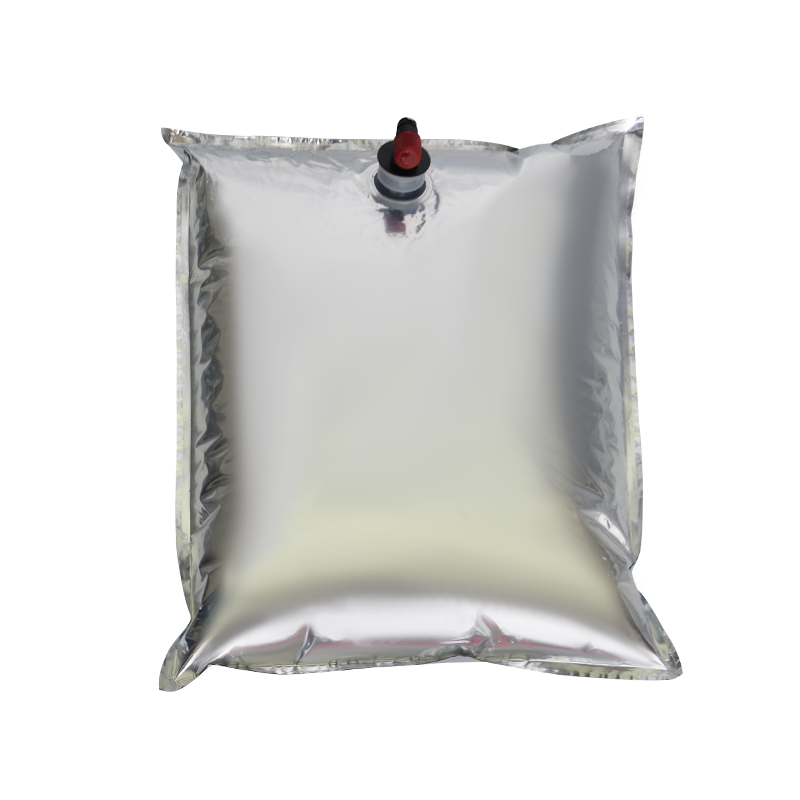

The core advantage of aseptic bag in box lies in its combination of aseptic bag and hard shell. Aseptic bags are usually made of materials that meet medical grade standards, such as polyethylene (PE) and polyvinyl chloride (PVC), which have barrier properties and sterilization resistance, and can effectively prevent the invasion of microorganisms. The hard shell provides additional protection, preventing physical damage and interference from the external environment, ensuring the sterility of the liquid in the bag.

During the manufacturing process, aseptic bag in box needs to undergo strict sterilization. Common sterilization methods include steam sterilization and ethylene oxide sterilization, which can ensure that the liquid in the bag remains sterile during packaging, transportation and storage. The sterile bag-in-box is also equipped with a high-seal design to ensure complete isolation of the environment inside and outside the bag, further improving the safety and reliability of the product.

The sterile bag-in-box is widely used in liquid packaging. In the medical field, it is widely used for the packaging of sensitive liquids such as blood products, nutrient solutions, and vaccines. These liquids usually require sterile conditions to maintain their activity and effectiveness, and the sterile bag-in-box can provide this necessary guarantee. In the field of biotechnology, sterile bags-in-box are also used for the packaging of key raw materials such as cell culture media and growth factors, ensuring the accuracy and reliability of scientific research experiments.

The convenience of sterile bags-in-box is also one of the important reasons for its popularity. The hard shell design makes the sterile bag-in-box easy to carry and store, while the soft sterile bag facilitates the access and distribution of liquids. This design not only improves work efficiency, but also reduces the risk of contamination and ensures the quality and safety of the product.

With the advancement of science and technology, the design of sterile bags-in-box is also constantly innovating. Some manufacturers have begun to integrate smart sensors into sterile bags-in-box to monitor the status of the liquid in the bag in real time, including temperature, pressure, and sterility. These sensors can provide real-time data to help users better understand the status of the product and take timely measures to ensure the safety and effectiveness of the product.

As the innovative guardian of liquid packaging, aseptic bag-in-box plays an important role in medical, biotechnology and many industrial fields with its unique design concept and performance. It not only ensures the safety and effectiveness of the product, but also improves work efficiency and environmental protection. With the continuous advancement and innovation of technology, the future of aseptic bag-in-box will be brighter, injecting new vitality and opportunities into the field of liquid packaging.

English

English русский

русский