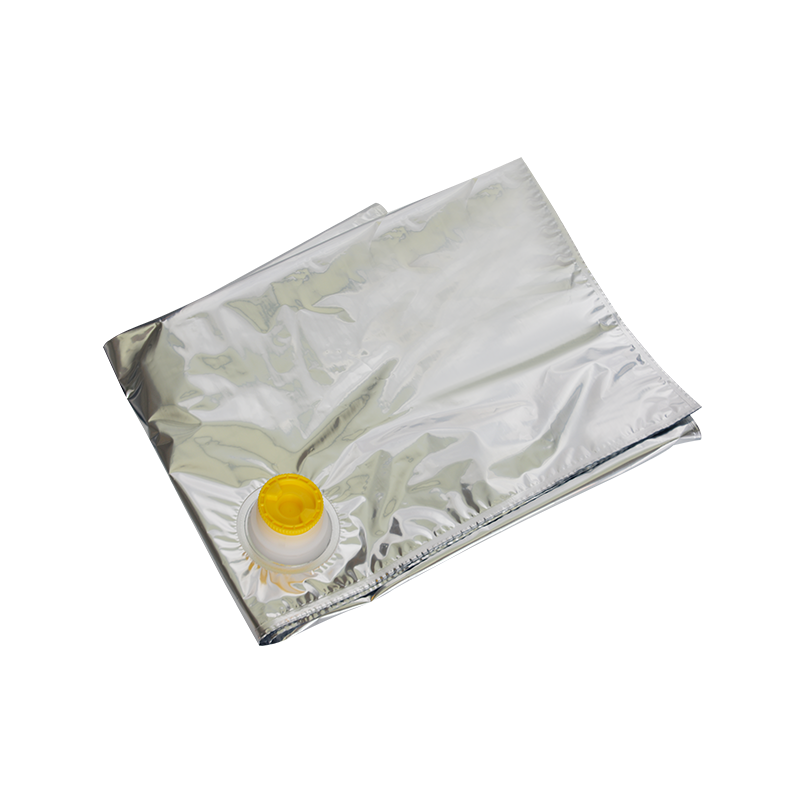

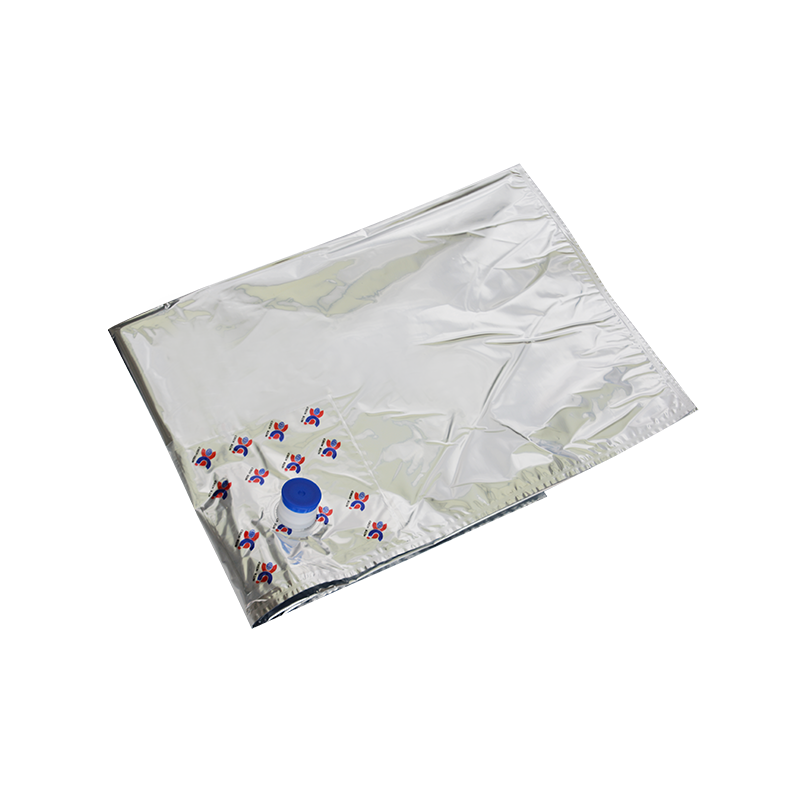

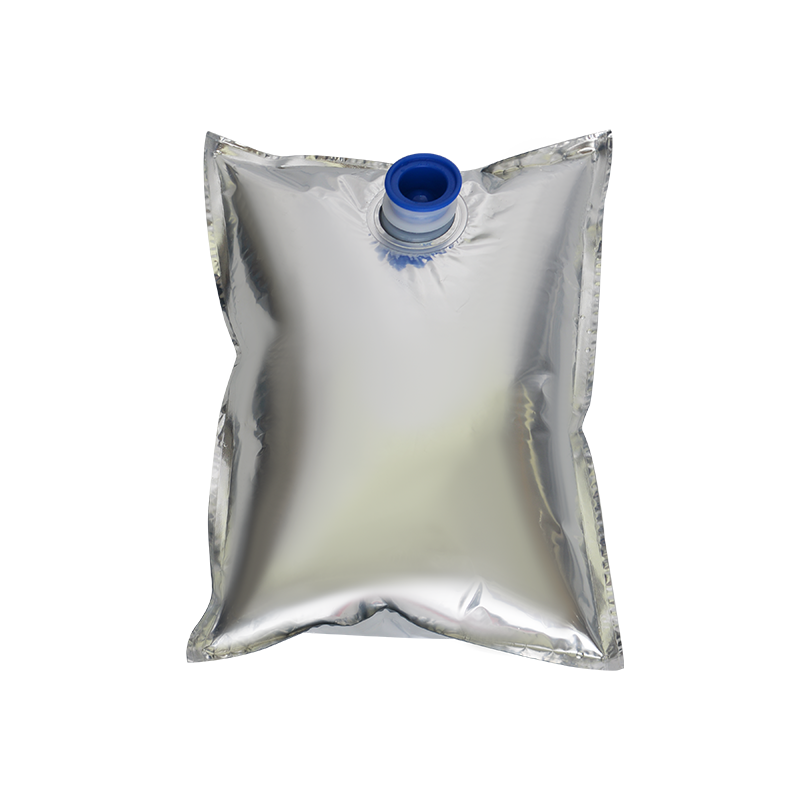

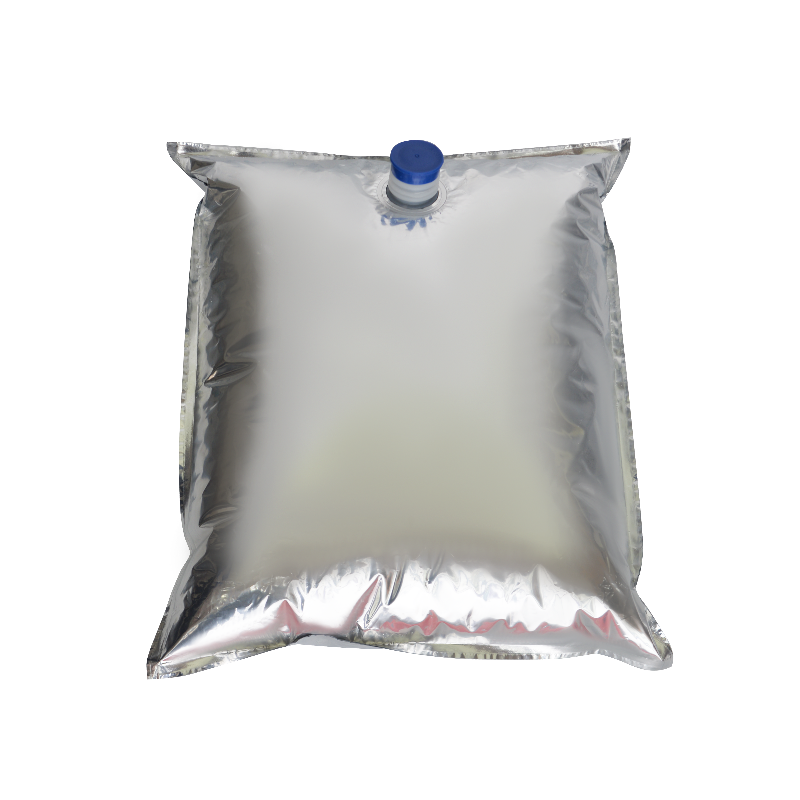

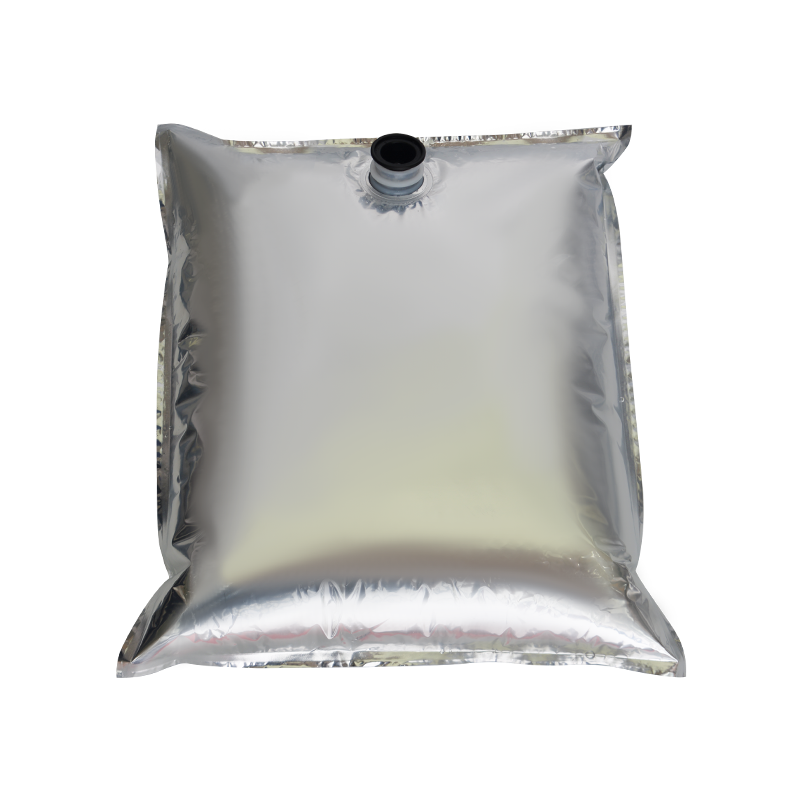

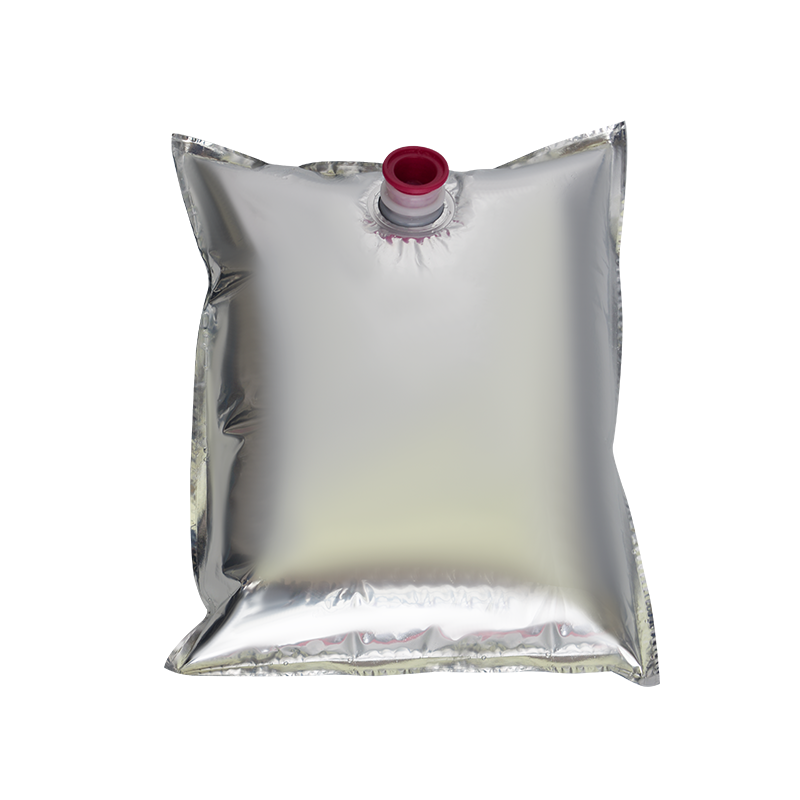

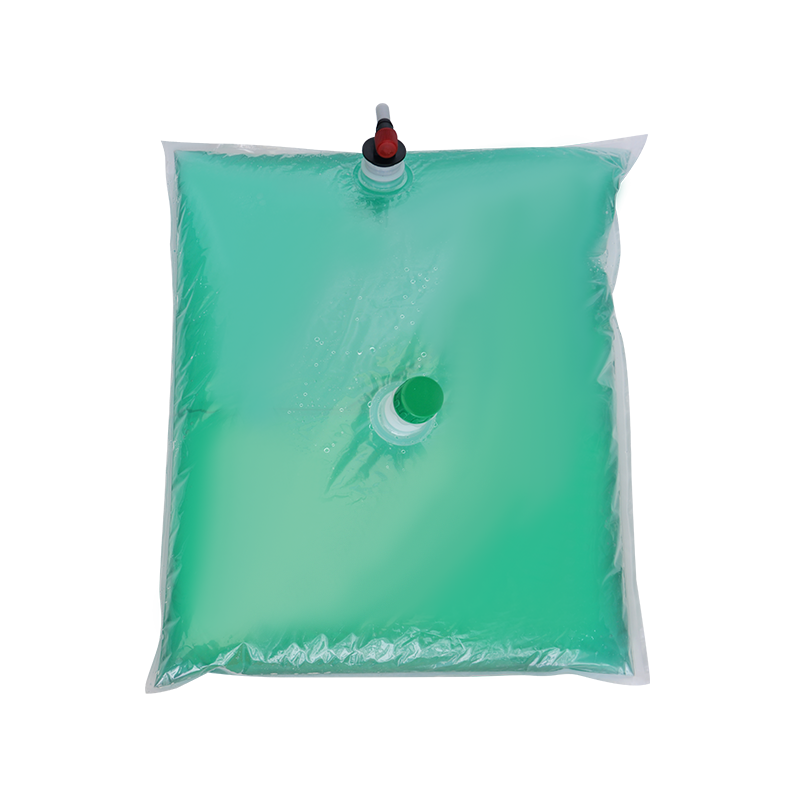

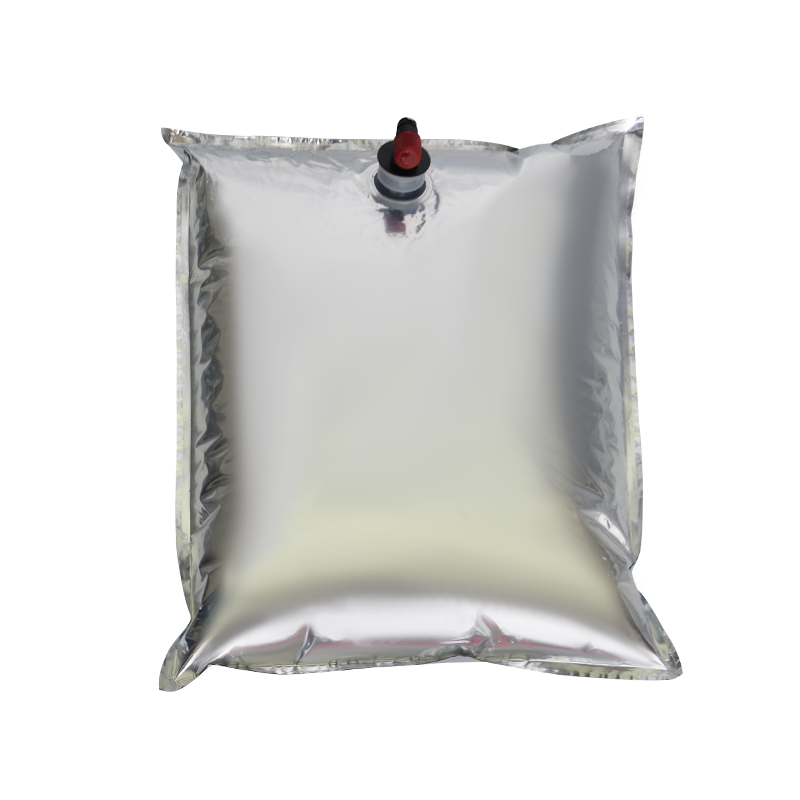

In the modern industrial field, sterile bags have become an indispensable packaging material for industries such as medical, food and pharmaceutical production due to their excellent performance advantages. Aseptic bags not only provide a safe and sterile packaging environment for products, but also have a series of excellent physical and chemical properties to ensure the quality and safety of products.

The core advantage of sterile bags lies in their excellent sterility. During the production process, sterile bags undergo strict sterilization treatment to ensure that the internal environment reaches a sterile state before packaging the product. This feature makes sterile bags have extremely high application value in the fields of medical, food and pharmaceutical production. In the medical field, sterile bags are widely used in the packaging of medical instruments, syringes and other medical devices, effectively reducing the risk of surgical infection; in the field of food and pharmaceutical production, sterile bags can ensure that products are free from microbial contamination during the packaging process, ensuring the quality and safety of products.

Sterile bags have excellent barrier properties and can effectively prevent the penetration of moisture, oxygen and other external substances. This feature gives sterile bags a significant advantage in protecting products from the influence of the external environment. In the food industry, aseptic bags can prevent food from getting damp, oxidized and deteriorating, and extend the shelf life of food; in the field of pharmaceutical production, aseptic bags can prevent drugs from getting damp, caking and contaminating, and ensure the quality and stability of drugs.

Aseptic bags can still maintain good performance in low temperature environments, which makes them widely used in the packaging of frozen and refrigerated products. In the food industry, aseptic bags can be used to package products that need to be stored at low temperatures, such as ice cream and quick-frozen foods; in the medical field, aseptic bags can be used to package biological products and vaccines that need to be stored at low temperatures.

Aseptic bags have good stability to most chemicals and solvents and are not prone to chemical reactions. This feature gives aseptic bags a significant advantage in packaging sensitive products such as chemicals and biological products. Aseptic bags can prevent chemical reactions between products and packaging materials, ensuring the safety and stability of products.

With the improvement of environmental awareness, aseptic bags are also paying more and more attention to environmental protection and sustainability in the design and production process. Many aseptic bags are made of recyclable materials, such as polyethylene (PE) and polypropylene (PP), which can be recycled and reused after being discarded, reducing pollution to the environment. In addition, the lightweight design of aseptic bags also reduces resource consumption and waste generation, further improving its environmental performance.

Aseptic bags are highly convenient and flexible in design and use. Aseptic bags can be customized according to different product shapes and sizes to meet the needs of different customers. At the same time, the opening and sealing design of aseptic bags makes it more convenient and quick to take and store products. Aseptic bags also have good printing performance, and various patterns and text information can be printed on the bag to improve the recognition and publicity effect of the product.

Aseptic bags have broad application prospects in the fields of medical, food and pharmaceutical production due to their excellent aseptic performance, excellent barrier performance, good low temperature resistance, excellent chemical stability, environmental protection and sustainability. With the continuous advancement of science and technology and the continuous development of the market, the performance of aseptic bags will continue to be improved and optimized, providing safer and more reliable packaging solutions for products in more fields.

English

English русский

русский